Surfactant Flooding: An Advanced Chemical Technique for Enhancing Oil Recovery

Surfactant flooding is a sophisticated oil recovery technique that has gained prominence in the petroleum industry for its effectiveness in mobilizing trapped oil from reservoir rocks. By reducing interfacial tension, surfactants enable better displacement of oil and improve its mobility, ultimately enhancing oil recovery rates. This article explores the principles, applications, benefits, challenges associated with surfactant flooding in oil reservoirs and how simulation technology is used in the planning, design, optimization, and evaluation of surfactant flooding projects for enhanced oil recovery (EOR).

Understanding Surfactant Flooding in Oil Recovery

Surfactants, or surface-active agents, are amphiphilic molecules with hydrophobic (water-repellent) and hydrophilic (water-attracting) regions. When introduced into a reservoir, surfactants adsorb onto oil-water interfaces, forming micelles or microemulsions. This reduces the interfacial tension between oil and water, allowing trapped oil droplets to detach from rock surfaces and migrate towards production wells more efficiently.

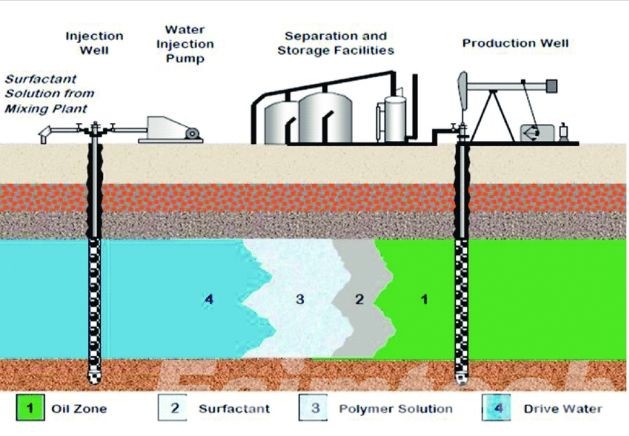

Surfactant flooding is a method employed in enhanced oil recovery (EOR) to improve the extraction of oil from reservoirs. This method involves the injection of surfactants, along with other chemicals, into the reservoir to alter the interfacial tension between oil, water, and rock surfaces.

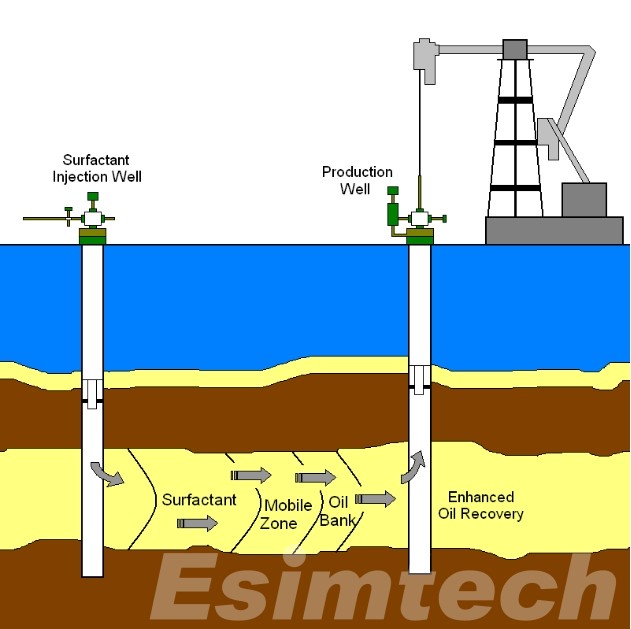

How Does Surfactant Flooding Work

Surfactant flooding operates on several fundamental principles rooted in interfacial chemistry and fluid dynamics.

1. Interfacial Tension Reduction

Surfactants are amphiphilic molecules with hydrophilic (water-attracting) and hydrophobic (oil-attracting) components. When injected into the reservoir, surfactants adsorb onto the interface between oil and water. This reduces the interfacial tension between the two fluids, making it easier for water to displace oil from the reservoir rock surfaces. Lower interfacial tension enables trapped oil droplets to detach from the pore surfaces and move towards production wells more efficiently.

2. Wettability Alteration

Surfactants can alter the wettability of reservoir rocks, affecting how fluids interact with the rock surfaces. In many cases, reservoir rocks exhibit mixed wettability, meaning they are partially water-wet and partially oil-wet. Surfactants can modify the wettability towards a more water-wet condition, which improves the affinity of the rock for water and enhances oil displacement. This wettability alteration further facilitates the mobilization of trapped oil and improves recovery efficiency.

3. Micelle Formation and Solubilization

Surfactants have the ability to form micelles or microemulsions in the presence of oil and water. In micellar solutions, surfactant molecules self-assemble into aggregates known as micelles, with their hydrophilic heads facing outward and hydrophobic tails clustered in the core. These micelles can solubilize hydrophobic components such as oil, forming stable complexes that aid in oil mobilization and transport through the reservoir. By enhancing the solubility of oil in water, surfactant flooding improves the recovery of trapped hydrocarbons.

4. Improvement of Sweep Efficiency

Surfactant flooding improves the sweep efficiency of injected fluids within the reservoir. Sweep efficiency refers to the ability of injected fluids to displace and recover oil from the entire reservoir volume. By reducing interfacial tension and altering wettability, surfactants facilitate more uniform fluid flow and better coverage of the reservoir, ensuring that oil trapped in remote regions and bypassed zones is effectively mobilized and recovered.

5. Optimization of Mobility Control

Surfactant flooding helps optimize mobility control within the reservoir, particularly in heterogeneous formations with varying permeabilities and porosities. By reducing the mobility contrast between injected water and displaced oil, surfactants mitigate the risk of fingering and channeling, which can lead to inefficient sweep and early breakthrough of water. This improved mobility control ensures a more balanced displacement of oil throughout the reservoir and maximizes oil recovery efficiency.

Applications and Benefits of Surfactant Flooding

1. Enhanced Oil Recovery (EOR)

Surfactant flooding is primarily employed as an enhanced oil recovery technique to extract additional oil from reservoirs beyond what can be recovered using primary and secondary recovery methods. By reducing interfacial tension and altering wettability, surfactants improve the displacement efficiency of injected fluids, facilitating the mobilization and recovery of residual oil trapped in the reservoir pores.

2. Increased Sweep Efficiency

Surfactant flooding enhances the sweep efficiency of injected fluids within the reservoir. Sweep efficiency refers to the ability of injected fluids to contact and displace oil from the entire reservoir volume. By reducing interfacial tension and promoting uniform fluid flow, surfactants ensure better coverage of the reservoir and improved displacement of oil from bypassed zones and remote regions, maximizing recovery efficiency.

3. Reduced Water Production

Surfactant flooding helps minimize water production by improving the control of water-oil mobility within the reservoir. By reducing interfacial tension and altering wettability, surfactants mitigate the risk of early breakthrough of injected water, which can lead to excessive water production. This results in a lower water cut, allowing for a higher proportion of oil to be produced from the reservoir.

4. Environmentally Friendly

Compared to other EOR techniques such as steam injection or chemical flooding, surfactant flooding is relatively environmentally friendly. It typically involves the use of biodegradable surfactants and does not generate significant greenhouse gas emissions or surface impacts. As a result, surfactant flooding is often favored for its lower environmental footprint and compatibility with sustainability initiatives.

5. Versatility Across Reservoir Types

Surfactant flooding can be applied across various types of reservoirs, including sandstone, carbonate, and fractured formations. It is effective in both oil-wet and water-wet reservoirs, making it a versatile solution for a wide range of geological conditions. Additionally, surfactant flooding can be tailored to specific reservoir characteristics through the selection of surfactant formulations and injection strategies, maximizing its applicability and effectiveness.

6. Improved Oil Recovery Economics

Surfactant flooding can lead to significant improvements in oil recovery economics by enhancing production rates and extending the economic life of oil fields. While surfactant flooding requires initial investment in surfactants, injection equipment, and reservoir monitoring systems, the resulting increase in oil production and reserve additions can justify these costs over the long term. Economic feasibility assessments are essential to evaluate the potential benefits and optimize project economics.

Challenges and Solutions in the Use of Surfactant Flooding for Enhanced Oil Recovery

1. Surfactant Selection and Formulation

Challenge: Selecting the appropriate surfactant formulation tailored to the specific reservoir conditions can be challenging due to the complex interactions between surfactants, reservoir fluids, and rock surfaces.

Solution: Conduct comprehensive laboratory tests and reservoir simulations to evaluate the performance of different surfactant formulations under reservoir conditions. Utilize advanced analytical techniques and computer modeling to optimize surfactant selection and formulation for maximum effectiveness.

2. Surfactant Retention and Losses

Challenge: Surfactants may adsorb onto reservoir rocks, become trapped in pore spaces, or be degraded by reservoir fluids, reducing their effectiveness and necessitating higher injection volumes.

Solution: Develop surfactant formulations with enhanced retention properties, such as alkyl ethoxylated sulfates or alkyl polyglucosides, which exhibit lower adsorption tendencies. Implement surfactant preflushes or additives to minimize surfactant losses and enhance reservoir penetration. Utilize surfactant recycling and re-injection strategies to improve overall efficiency and reduce consumption.

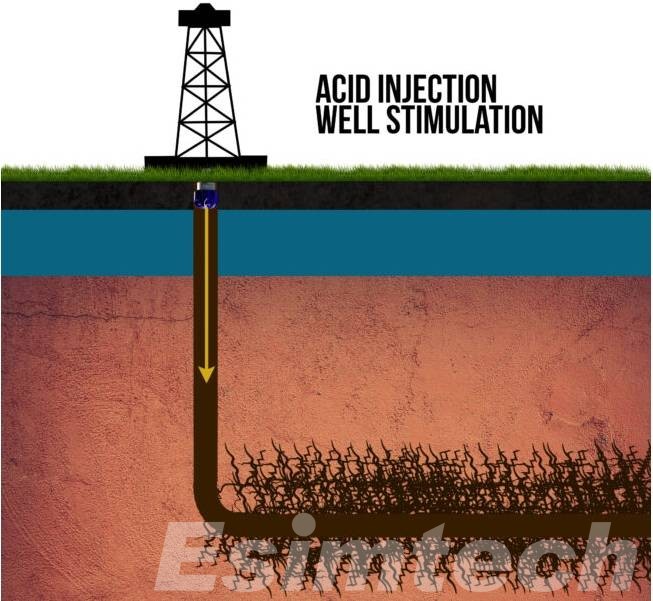

3. Wettability Alteration and Reservoir Heterogeneity

Challenge: Achieving and maintaining the desired wettability alteration in heterogeneous reservoirs with varying rock properties can be challenging, leading to uneven oil displacement and suboptimal recovery.

Solution: Employ surfactant formulations and injection strategies specifically designed to induce and sustain wettability alteration in diverse reservoir conditions. Utilize advanced reservoir characterization techniques, such as well logging and core analysis, to assess reservoir heterogeneity and tailor surfactant flooding designs accordingly. Implement periodic monitoring and adjustment of injection parameters to optimize wettability alteration and maximize oil recovery efficiency.

4. Chemical Compatibility and Interactions

Challenge: Surfactants may interact with other chemicals used in the process, such as polymers or alkaline agents, leading to precipitation, emulsion formation, or reduced performance.

Solution: Conduct compatibility testing to assess potential interactions between surfactants and other chemicals before injection. Utilize surfactant-polymer systems or surfactant-alcohol co-solvents to mitigate compatibility issues and enhance overall performance. Implement real-time monitoring and control systems to detect and mitigate chemical interactions during injection operations.

5. Cost Considerations and Economics

Challenge: Surfactant flooding can be capital-intensive due to the cost of surfactants, injection equipment, and reservoir monitoring systems, raising concerns about economic feasibility and project viability.

Solution: Conduct comprehensive economic evaluations to assess the potential benefits and risks associated with surfactant flooding projects. Optimize injection strategies, reservoir management practices, and surfactant formulations to maximize the return on investment and minimize operational costs. Explore alternative financing options, collaborative partnerships, and government incentives to support the implementation of surfactant flooding projects.

6. Environmental Impact and Regulatory Compliance

Challenge: Surfactant flooding operations may raise environmental concerns related to chemical usage, water consumption, and potential impacts on groundwater quality.

Solution: Implement stringent environmental management practices and regulatory compliance measures to mitigate potential risks and ensure responsible stewardship of natural resources. Utilize biodegradable surfactants, water recycling systems, and environmentally friendly additives to minimize the environmental footprint of surfactant flooding operations. Engage with regulatory authorities, stakeholders, and local communities to address environmental concerns and build trust in the sustainability of surfactant flooding projects.

How Simulation Technology is Used in Surfactant Flooding Projects for Enhanced Oil Recovery

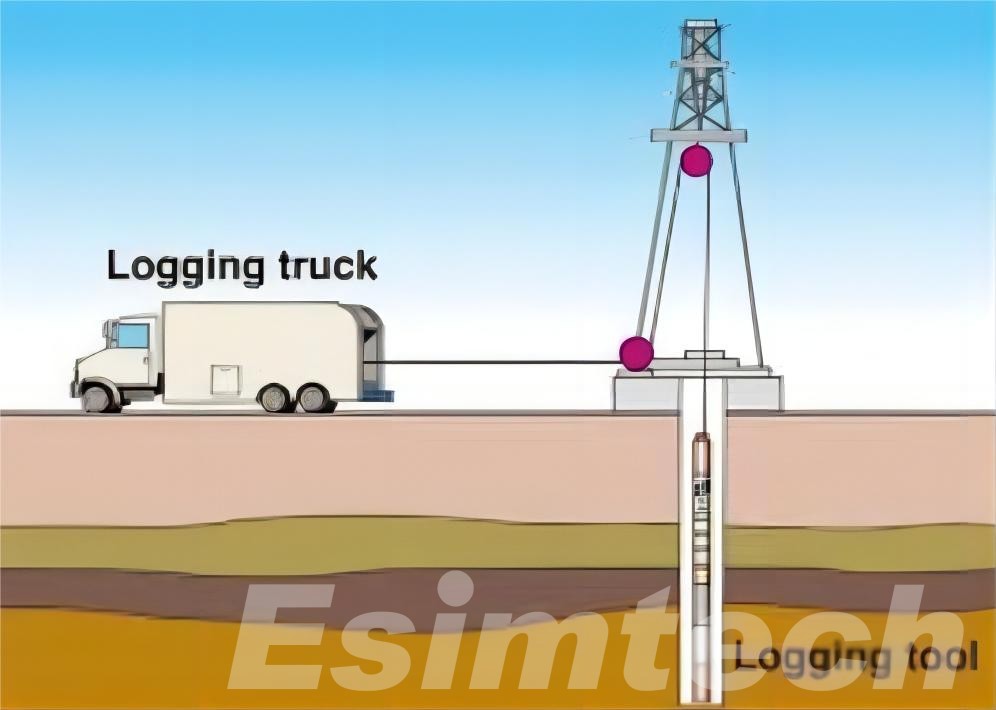

1. Reservoir Characterization

Simulation models begin with detailed reservoir characterization, which involves gathering data on rock properties, fluid composition, reservoir geometry, and other pertinent parameters. Advanced techniques such as well logging, core analysis, and seismic imaging are utilized to generate 3D geological models of the reservoir.

2. Fluid Behavior Modeling

Surfactant flooding simulations involve modeling the behavior of fluids in the reservoir, including the interactions between surfactants, oil, water, and rock surfaces. Fluid properties such as interfacial tension, viscosity, and solubility are incorporated into the simulation models to accurately predict fluid flow and displacement mechanisms.

3. Surfactant Formulation and Injection Strategy Optimization

Simulation technology allows engineers to optimize surfactant formulations and injection strategies by simulating various scenarios and assessing their impact on oil recovery efficiency. Parameters such as surfactant concentration, injection rate, injection timing, and well placement can be adjusted to maximize sweep efficiency and minimize surfactant losses.

4. Wettability Alteration Modeling

Surfactant flooding often involves inducing wettability alterations in reservoir rocks to improve oil recovery. Simulation models simulate the effects of surfactant-induced wettability alterations on fluid flow behavior, capillary pressure, and oil displacement efficiency. This enables engineers to design surfactant flooding projects that optimize wettability alteration and enhance oil recovery rates.

5. Sensitivity Analysis and Uncertainty Assessment

Simulation technology allows for sensitivity analysis and uncertainty assessment to evaluate the impact of various parameters and uncertainties on project outcomes. This helps identify key factors influencing project performance and assess the reliability of simulation results. Sensitivity analysis can be performed on parameters such as reservoir permeability, porosity, surfactant properties, and injection conditions.

6. Real-Time Monitoring and Decision Support

Advanced simulation tools enable real-time monitoring of surfactant flooding operations and provide decision support for field engineers. Real-time data from production wells, injection wells, and monitoring sensors can be integrated into simulation models to track project progress, assess performance deviations, and make informed operational decisions.

7. Performance Evaluation and Post-Simulation Analysis

After surfactant flooding operations are completed, simulation technology is used to evaluate project performance and conduct post-simulation analysis. Engineers compare simulation results with actual field data to validate model accuracy and identify areas for improvement. Lessons learned from post-simulation analysis inform future surfactant flooding projects and contribute to ongoing optimization efforts.

Conclusion

Surfactant flooding represents a sophisticated approach to oil recovery that leverages chemical techniques to enhance oil displacement and extraction from reservoirs. While challenges such as surfactant selection, retention, and reservoir heterogeneity must be addressed, ongoing advancements and innovations in surfactant formulations and injection strategies continue to expand the applicability and effectiveness of this EOR technique.

Simulation technologies play a vital role in the successful implementation of surfactant flooding projects by providing a comprehensive understanding of reservoir behavior, optimizing injection strategies, assessing project risks, and supporting real-time decision-making.