Snubbing Operations in Offshore Environments: Challenges and Solutions

Offshore oil and gas extraction is a critical industry that meets global energy demands. As reserves onshore become increasingly depleted, companies are pushing further offshore, where operational challenges intensify. Among the complex procedures carried out in these environments is snubbing, a specialized operation critical for well intervention, workover, and drilling activities. This article explores the intricacies of snubbing operations in offshore environments, highlighting the associated challenges and the strategies employed to mitigate these issues.

Oil and Gas Offshore Environments

Offshore oil and gas environments are among the most challenging work settings globally, characterized by their remote locations, harsh weather conditions, and complex underwater infrastructures. These environments are typically found in deep or ultra-deep waters, requiring platforms or floating production systems to extract hydrocarbons from beneath the seabed. The conditions in these environments necessitate advanced technology and highly skilled personnel to maintain safety and operational efficiency.

In offshore environments, well pressure management is critical due to the increased risk of blowouts and other dangerous incidents. The depth and pressure of offshore wells often exceed those encountered in onshore operations, making snubbing a preferred method for well intervention, especially when the well cannot be killed using conventional means.

Challenges of Offshore Snubbing Operations

Offshore snubbing operations face a distinct set of challenges compared to onshore operations, influenced by the unique and often extreme conditions of the offshore environment, thus significantly impact the efficiency, safety, and cost of operations. Here’s a more detailed look at the primary challenges encountered in offshore snubbing operations:

1. Harsh Environmental Conditions

Offshore environments are known for their severe and unpredictable weather conditions. Platforms and rigs are exposed to high winds, rough seas, and extreme temperatures, which can adversely affect snubbing operations. High winds can sway the platform, making it difficult to maintain the stability of equipment and the accuracy of snubbing operations. Rough seas can cause the platform to move or tilt, further complicating the task of inserting or removing pipe or tubing under pressure. These conditions not only increase the risk of operational delays but also pose significant safety risks to personnel working on the platform.

Additionally, the corrosive nature of the marine environment accelerates the wear and tear on equipment, necessitating frequent maintenance and the use of more robust, corrosion-resistant materials. Ensuring that all equipment can withstand these harsh conditions is crucial for maintaining operational integrity and safety.

2. Logistical Complexities

The logistical challenges of offshore snubbing operations stem from the remote and often isolated locations of offshore platforms. Transporting the necessary equipment, materials, and personnel to and from these sites is both time-consuming and expensive. The logistics of handling heavy and oversized snubbing units, along with the limited space on offshore platforms, require careful planning and coordination.

Offshore platforms are generally confined spaces, which can make the setup and operation of snubbing units more difficult. The need for precision in positioning and anchoring equipment adds to the complexity of operations. Any delays or issues in logistics can result in extended downtime, increased costs, and potential operational risks.

3. Well Pressure and Depth

The depth and pressure of offshore wells often exceed those found onshore, introducing additional challenges for snubbing operations. Managing high-pressure wells requires sophisticated equipment capable of withstanding extreme conditions. The deeper the well, the greater the pressure, and the more complex the snubbing operation becomes. Specialized snubbing units must be designed to handle these pressures, and their operation requires a high level of expertise and precision.

The increased depth also means that any issues encountered during snubbing operations can be more challenging to address. For example, if a pipe becomes stuck or if there is a problem with the well, retrieving equipment from great depths can be both costly and time-consuming.

4. Safety Risks

Safety is a paramount concern in offshore snubbing operations due to the combination of high-pressure environments, confined spaces, and the complexity of the equipment involved. The potential for catastrophic events, such as blowouts, is heightened in offshore settings where well control is critical. Ensuring the safety of personnel working on the platform is a continuous challenge, requiring strict adherence to safety protocols and regular training.

The confined spaces of offshore platforms can also complicate emergency responses. In the event of an accident, such as a blowout or equipment failure, the ability to quickly and effectively respond is crucial to preventing injury and mitigating damage. This makes the development of robust emergency response plans and regular drills an essential part of offshore snubbing operations.

5. Environmental Impact

The potential environmental impact of offshore snubbing operations is another significant challenge. Any accidental discharge of hydrocarbons or other contaminants into the marine environment can have severe ecological consequences. The remote location of offshore platforms can also hinder the speed and effectiveness of environmental response efforts.

Mitigating environmental risks requires the implementation of stringent environmental safeguards, including the use of blowout preventers (BOPs), containment systems, and comprehensive spill response plans. Continuous monitoring and adherence to environmental regulations are necessary to minimize the risk of incidents and ensure rapid response if an issue arises.

Solutions and Mitigation Strategies for Offshore Snubbing

To address the multifaceted challenges of offshore snubbing operations, a combination of advanced technology, procedural enhancements, and strategic planning is employed. Here’s a deeper look into the solutions and mitigation strategies that are critical for successful offshore snubbing:

Advanced Technology and Equipment

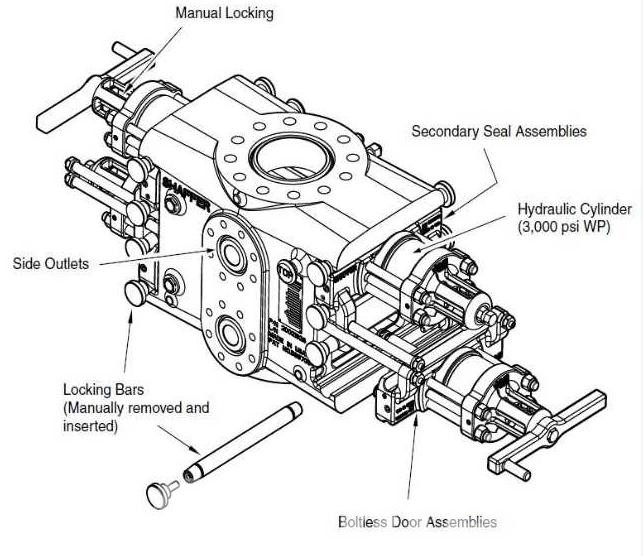

- Specialized Snubbing Units: Offshore snubbing units are designed to operate efficiently in the constrained and challenging environment of offshore platforms. These units are engineered to be more compact and modular, fitting into the limited space available while still delivering high performance. They are built to withstand harsh marine conditions and are often equipped with enhanced hydraulic systems to manage the high pressures associated with deepwater wells.

- High-Pressure and High-Temperature (HPHT) Equipment: Given the extreme conditions of offshore wells, HPHT-rated equipment is essential. This equipment is designed to handle the significant pressures and temperatures found in deepwater wells, ensuring reliable performance and safety during snubbing operations. Technologies such as advanced blowout preventers (BOPs) and reinforced casing and tubing are crucial in managing these high-pressure environments.

- Enhanced Control Systems: Modern snubbing units are equipped with sophisticated control systems that provide real-time data on well conditions. These systems allow operators to monitor pressure, temperature, and other critical parameters continuously. Advanced control systems with automation capabilities enable precise adjustments during operations, enhancing safety and efficiency.

Training and Expertise

- Specialized Training Programs: Given the complexity of offshore snubbing operations, specialized training programs are essential for preparing personnel. These programs include both theoretical knowledge and practical simulations, ensuring that crews are well-versed in the specific challenges of offshore environments. Regular refresher courses and training updates help keep skills current and address new developments in technology and procedures.

- Simulation and Drills: Realistic simulations and emergency response drills are integral to preparing teams for offshore snubbing operations. Simulations allow personnel to practice handling various scenarios, including equipment failures and emergency situations, in a controlled environment. These drills help reinforce safety protocols and improve crew readiness.

- Expertise and Experience: The experience of personnel is invaluable in offshore operations. Experienced operators and engineers bring a wealth of knowledge and problem-solving skills to the table, which is critical for managing the complex dynamics of offshore snubbing. Mentoring and knowledge sharing among experienced and less experienced team members foster a culture of safety and continuous improvement.

Real-Time Monitoring and Automation

- Integrated Data Systems: Real-time monitoring systems collect data from various sensors and instruments installed on the snubbing unit and the well. This data is processed and displayed on control panels, allowing operators to make informed decisions quickly. These systems help in detecting early signs of potential issues, such as pressure anomalies or equipment malfunctions, allowing for prompt corrective actions.

- Automated Systems and Robotics: Automation and robotics play a significant role in reducing human error and improving operational efficiency. Automated systems can perform repetitive tasks with high precision, and robotic systems can handle dangerous or complex tasks in hazardous environments, thus enhancing safety for the crew.

- Remote Operation Capabilities: In some offshore settings, snubbing operations can be controlled remotely from a command center. This capability allows for greater flexibility and safety, as operators can manage operations from a secure location, minimizing their exposure to potential hazards.

Rigorous Safety Protocols

- Comprehensive Risk Assessments: Before commencing snubbing operations, thorough risk assessments are conducted to identify potential hazards and develop mitigation strategies. These assessments cover various aspects, including equipment integrity, environmental conditions, and personnel safety.

- Safety Audits and Inspections: Regular safety audits and equipment inspections are performed to ensure that all systems are functioning correctly and adhere to safety standards. These audits help identify potential issues before they escalate, ensuring that safety measures are continuously upheld.

- Emergency Response Planning: Detailed emergency response plans are developed and practiced to prepare for potential incidents such as blowouts or equipment failures. These plans outline procedures for evacuation, containment, and communication with emergency response teams. Ensuring that all personnel are familiar with these plans and trained in emergency procedures is crucial for minimizing the impact of any incidents.

Environmental Safeguards

- Blowout Preventers (BOPs): BOPs are critical in controlling well pressure and preventing blowouts during snubbing operations. Advanced BOP systems with redundant safety features are used to ensure that well control is maintained at all times.

- Containment and Spill Response: Effective containment systems and spill response strategies are essential for minimizing environmental impact. These systems include barriers and skimmers designed to contain and recover any spilled hydrocarbons. Regular drills and maintenance of these systems ensure readiness in the event of a spill.

- Continuous Environmental Monitoring: Monitoring systems are employed to track environmental conditions and detect any signs of pollution or other impacts. This proactive approach helps in quickly addressing any environmental concerns and ensuring compliance with regulatory requirements.

Snubbing operations in offshore environments face challenges such as harsh weather, high-pressure wells, and logistical complexities. However, through advanced technology, real-time monitoring, stringent safety protocols, and specialized training, these challenges are effectively managed. Continued innovation and adherence to best practices are crucial for safe and efficient offshore operations.