Safety Considerations in Wellhead Control Systems: Preventing Blowouts

The oil and gas industry relies heavily on wellhead control systems to maintain safe operations and prevent disasters such as blowouts. These systems are designed to monitor, regulate, and manage the flow of hydrocarbons from a well, ensuring safe extraction while minimizing risks. A blowout, the uncontrolled release of oil or gas from a well, is one of the most catastrophic incidents that can occur, making wellhead control systems vital for operational safety.

What is a Wellhead Control System?

A wellhead control system is a critical mechanism used in oil and gas drilling operations to manage the pressure and flow of hydrocarbons from a well. It serves as the primary safety barrier between the well’s subsurface pressure and the surface facilities. The primary objective of a wellhead control system is to prevent uncontrolled releases of oil, gas, or drilling fluids during production, maintenance, or drilling operations.

Wellhead control systems ensure the well’s integrity, allowing operators to shut in or regulate the well under both normal and emergency conditions. These systems include a combination of mechanical, hydraulic, and electronic components that monitor real-time conditions and provide the ability to intervene if unsafe situations arise.

Components of Wellhead Control Systems

Wellhead control systems are composed of several essential components that work together to maintain safety and control. Each component plays a specific role in monitoring and regulating well conditions to prevent blowouts and other hazards.

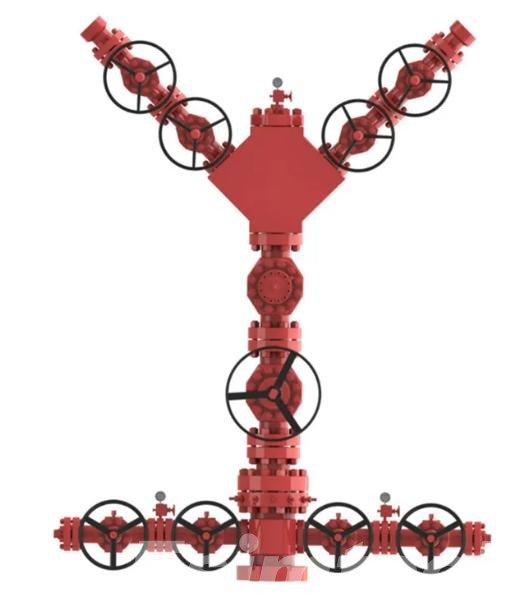

- Wellhead

The wellhead is the physical structure installed at the surface of the well. It provides structural support and pressure containment for the production casing, tubing, and valves. The wellhead connects the drilling equipment with the oil or gas reservoir, making it an integral part of both drilling and production operations.

- Blowout Preventer (BOP)

The blowout preventer is a key safety device that prevents uncontrolled flow from the well. It consists of high-pressure valves that can be closed in an emergency to stop the flow of oil, gas, or other fluids. BOPs are critical during drilling operations and are designed to withstand the extreme pressures encountered in the well.

- Master Valves

Master valves, located on the wellhead, are used to control the flow of oil and gas from the well. These are the primary control points for stopping or regulating flow during production or emergencies.

- Choke Manifold

A choke manifold is a system of valves and chokes used to control well pressures and flow rates. It plays a critical role in managing pressure during production, testing, or maintenance operations, allowing for precise control of the well’s output.

- Hydraulic Control Panel

The hydraulic control panel is responsible for actuating the wellhead valves and BOPs. In most modern systems, this panel receives inputs from sensors monitoring pressure, flow, and other parameters, allowing for automatic or manual adjustments to be made remotely. The hydraulic panel ensures rapid response in emergencies, such as a blowout scenario.

- Emergency Shutdown System (ESD)

The ESD system is designed to shut in the well in the event of abnormal conditions, such as excessive pressure or flow rates. It provides an additional layer of safety by automatically closing critical valves when predetermined conditions are exceeded, preventing blowouts or other hazards.

Key Safety Considerations in Wellhead Control Systems

Ensuring the safety and reliability of wellhead control systems is critical in preventing blowouts and maintaining operational integrity in oil and gas drilling. The following four key safety considerations are essential for minimizing risks and ensuring smooth, safe operations.

Regular Maintenance and Testing

Routine maintenance and testing of wellhead components are essential to ensure their proper functioning during emergency situations. This includes regular inspections, servicing, and testing of Blowout Preventers (BOPs), control panels, pressure sensors, and other critical elements.

- Importance: Over time, wear and tear can lead to equipment degradation, potentially compromising safety. Regular maintenance helps identify and address issues before they escalate, ensuring all components are operational and reliable.

- Protocols: Operators should adhere to manufacturer guidelines and industry best practices regarding maintenance schedules. This typically involves conducting pressure tests, functional tests, and inspections at defined intervals and after any significant operational changes.

- Documentation: Maintaining detailed records of all maintenance activities, inspections, and tests provides a history of the equipment’s reliability and can be crucial during safety audits or regulatory inspections.

Operator Training

Comprehensive training programs for operators are vital for effective safety management in wellhead control systems. Operators must be well-versed in the operation of the equipment, emergency procedures, and the specific risks associated with wellhead operations.

- Training Focus: Training should cover not only standard operating procedures but also emergency response protocols for various scenarios, including blowouts, leaks, and equipment failures. This may involve classroom instruction, hands-on training, and simulations.

- Continuous Education: Regular refresher courses and drills help ensure that operators stay current with the latest safety practices and technologies. This is especially important as new equipment or procedures are introduced.

- Assessment: Implementing assessment procedures to evaluate operator competency can help identify areas for improvement and ensure that all personnel meet safety standards before they are assigned to critical tasks.

Emergency Response Planning

Developing and regularly updating emergency response plans is crucial for minimizing the effects of potential incidents at the wellhead. These plans must address a range of scenarios, including blowouts, leaks, and equipment failures.

- Plan Development: Emergency response plans should clearly define specific roles and responsibilities for personnel, establish procedures for evacuating staff, and outline safe shutdown processes for operations. Effective communication protocols are essential to ensure that everyone involved understands their responsibilities during an emergency.

- Regular Drills: Conducting frequent drills and simulations of various emergency scenarios is vital for familiarizing personnel with the emergency response plan. This practice enhances their ability to execute the plan effectively under pressure and helps identify any shortcomings that may need to be addressed.

- Review and Revision: Emergency response plans should be periodically reviewed and updated to incorporate insights gained from drills, real incidents, and any changes in operational practices or regulations. This ongoing review process ensures that the plans remain relevant and effective in addressing current risks.

Real-Time Monitoring Systems

Implementing real-time monitoring systems is crucial for maintaining safe operations in wellhead control systems. Continuous monitoring allows for immediate detection of any abnormal conditions, enabling prompt action.

- Sensor Integration: Utilizing advanced sensors to monitor pressure, temperature, flow rates, and other critical parameters can provide valuable data for operators. These sensors should be strategically placed throughout the wellhead control system to provide comprehensive coverage.

- Data Analysis: Integrating data analytics tools with monitoring systems can enhance the ability to predict potential issues. By analyzing trends and deviations from normal operating parameters, operators can intervene before conditions escalate to dangerous levels.

- Alerts and Notifications: Setting up automated alerts for operators when sensor readings exceed predefined thresholds ensures that any anomalies are addressed promptly. These alerts can facilitate quick decision-making and reduce the likelihood of catastrophic events.

By prioritizing these key safety considerations, operators can significantly enhance the safety and reliability of wellhead control systems, ultimately reducing the risk of blowouts and ensuring safer oil and gas extraction operations.

Technology and Innovation in Wellhead Control

Advancements in technology have revolutionized wellhead control systems, enhancing their safety, reliability, and efficiency. These innovations are crucial in mitigating risks such as blowouts and ensuring more effective management of oil and gas wells.

1. Automated Control Systems

Automated control systems have significantly improved the precision and reliability of wellhead operations. These systems can monitor real-time data on well conditions, such as pressure, temperature, and flow rates, and automatically adjust parameters to maintain safe operating conditions. By reducing reliance on human intervention, automation minimizes the risk of human error, especially during critical moments like pressure spikes or equipment failures.

2. Remote Monitoring and Control

The integration of Internet of Things (IoT) technology into wellhead control systems allows for remote monitoring and control. Operators can access real-time data and make critical adjustments from any location, improving response times in case of an emergency. This is particularly beneficial for offshore or remote drilling operations, where on-site intervention may be delayed.

3. Predictive Maintenance with AI and Data Analytics

Predictive maintenance, driven by artificial intelligence (AI) and data analytics, has become an essential innovation in wellhead safety. By analyzing historical data from sensors and equipment, these tools can identify patterns and predict when components are likely to fail. This allows operators to schedule maintenance before problems arise, reducing downtime and preventing catastrophic failures such as blowouts.

4. Smart Blowout Preventers (BOPs)

Smart BOPs, equipped with sensors and automated control features, represent a major leap in safety technology. These devices can provide real-time feedback on well conditions and initiate emergency shutdowns if abnormal pressure or flow conditions are detected. The integration of self-diagnosing capabilities ensures that the BOPs are always in optimal condition for immediate deployment.

These technological innovations not only improve the safety and efficiency of wellhead control systems but also pave the way for more sustainable and responsible resource extraction.

Wellhead control systems are critical to the safe and efficient operation of oil and gas drilling activities. As technology continues to evolve, the future of wellhead control systems promises even greater safety and efficiency, paving the way for responsible resource extraction in an increasingly demanding energy landscape.