Revolutionary Power of VR Training in the Oil and Gas Industry

Practical training is essential, but it can be costly, difficult to access, and risky, especially in industries like oil and gas. As technology evolves, proper training for service personnel becomes even more crucial to keep up with new equipment and methods. Failure to provide adequate training puts operations at risk. However, organizing training for oil rig employees is a complex task, requiring solutions to numerous challenges. By creating immersive and interactive experiences, VR training transcends traditional limitations, fostering a safer, more skilled, and adaptable workforce in the oil and gas industry.

Challenges Associated with Practical Training in the Oil and Gas Sector

1. High Cost

Practical training in the oil and gas sector can be prohibitively expensive due to the need for specialized equipment, facilities, and qualified instructors. Setting up and maintaining training facilities that accurately simulate real-world environments, such as drilling rigs or refineries, requires significant financial investment.

Additionally, Oil and gas fields are often situated in remote locations such as deserts or open seas, posing accessibility challenges. Companies typically rely on helicopters or motorboats to access these areas. Once personnel arrive, they often need to remain for extended periods since immediate return transportation may not be available. For oil industry companies aiming to conduct on-site training, this necessitates flying employees to the rig and arranging accommodation. So, the associated costs of such training endeavors are notably high.

2. High risk

Practical training in the oil and gas sector often involves working with hazardous materials, heavy machinery, and potentially dangerous environments. Ensuring the safety of trainees during practical training exercises is paramount but can be challenging, particularly when simulating high-risk scenarios. Throw in the harsh weather conditions, and you are getting a very dangerous affair exposing the trainees to a high risk of accident or injury. Inadequate safety measures or equipment failure during training sessions can lead to accidents or injuries, posing significant risks to trainees and instructors alike.

3. Skill Shortages

The oil and gas industry faces ongoing challenges related to workforce demographics, including an aging workforce and shortages of skilled labor in certain regions. Providing practical training opportunities to develop essential skills and competencies is critical for attracting and retaining talent within the industry. However, skill shortages can also impact the availability of qualified trainers and instructors, further exacerbating the challenges associated with practical training.

4. Limited Accessibility

Limited accessibility characterizes many oil and gas facilities, such as offshore rigs or remote drilling sites, often situated in isolated or hard-to-reach areas. This geographical challenge poses significant obstacles for trainees seeking hands-on training opportunities. The remote locations make it challenging to access training sites, resulting in logistical complexities and heightened costs associated with travel and accommodation arrangements. Such limitations hinder the efficiency of practical training programs and may necessitate innovative solutions to overcome geographical barriers and ensure effective skill development for personnel within the oil and gas

5. Environmental Considerations

The oil and gas industry operates in sensitive environmental settings, including offshore platforms, drilling sites, and refineries. Practical training activities must be conducted in a manner that minimizes environmental impacts and complies with regulatory requirements. Implementing environmentally sustainable practices within training programs, such as waste management and pollution prevention measures, adds complexity to the planning and execution of practical training exercises.

6. Difficulty to assess

The professional skills are best of all demonstrated in a live situation. No exam, test, quiz, or practice can truly show how well the trainee is prepared for the real work.

Since many professions in the oil and gas sector are subject to certification, it is especially important to verify that the quality of training is at an acceptable level.

To assess and certify the employees, companies still need to transfer them to the live rigs to have them demonstrate their proficiency. Again, this is a rather costly process.

It is precisely because of these difficulties that VR technology has become the key to solving the problem.

Main Applications of VR Training in Oil and Gas

Virtual reality (VR) is no longer a futuristic fantasy in the oil and gas industry; it’s a powerful tool revolutionizing training methods. Let’s delve deeper into some key applications:

Offshore Platform Operations

- Crane Operation: Trainees virtually pilot cranes amidst realistic weather conditions, practicing load calculations and precision maneuvers without real-world risks. This builds confidence and competency before taking the control on actual platforms.

- Well Intervention: Immerse trainees in virtual wellheads, where they practice handling equipment, identifying potential hazards, and navigating complex procedures like pressure control in a controlled environment. This experiential learning prepares them for real-world scenarios without endangering themselves or others.

- Confined Space Entry: VR simulations recreate confined spaces like tanks and vessels, allowing trainees to safely learn proper entry procedures, utilize safety equipment, and practice effective communication protocols. This builds crucial muscle memory for real-world confined space operations.

Pipeline Maintenance

- Inspection: Trainees navigate intricate 3D models of pipelines as virtual drones, honing their inspection skills by identifying corrosion, leaks, and other anomalies. This immersive training improves visual acuity and decision-making, leading to more effective pipeline maintenance and early detection of potential issues.

- Repair: Don virtual welding masks and step into realistic repair scenarios. Trainees practice intricate welding procedures, leak sealing techniques, and other essential tasks in a controlled environment. This builds proficiency and minimizes downtime when performing real-world repairs.

Emergency Preparedness

- Fire Drills: Experience realistic fire drills on virtual oil platforms. Trainees learn evacuation routes, practice firefighting techniques, and refine communication protocols. This immersive training improves preparedness and response times in real emergencies, potentially saving lives and minimizing damage.

- Spill Response: Respond to simulated oil spills in VR, practicing containment procedures, using specialized equipment, and coordinating response efforts with virtual teams. This fosters effective collaboration and rapid decision-making in critical situations, leading to a more efficient and effective response to potential environmental hazards.

Soft Skills Development

- Communication: Role-play challenging conversations with colleagues, supervisors, or stakeholders in VR simulations. This gamified approach hones clear and effective communication skills under pressure, fostering collaboration and understanding within teams.

- Teamwork: Collaborate with virtual teammates to complete complex tasks like platform maintenance or emergency response. VR creates realistic scenarios where trainees practice coordination, leadership, and problem-solving skills in dynamic situations, ensuring a well-functioning and efficient team structure.

- Decision-Making: Immerse trainees in ethically ambiguous scenarios and face critical decisions in simulated high-pressure situations. VR helps develop the ability to make quick and informed choices with potential consequences, preparing them for real-world complexities and ensuring responsible and ethical decision-making.

Benefits of VR Training in Oil and Gas

By including virtual reality in their training programs, companies can achieve multiple benefits by resolving the major problems related to practical training.

- Improved Safety: VR allows workers to engage in training exercises within realistic yet controlled environments, mitigating the potential risks associated with hands-on training in hazardous settings. By simulating various scenarios, workers can practice safety protocols and emergency procedures without endangering themselves or others, ultimately reducing the occurrence of workplace accidents and injuries.

- Cost Savings: Implementing VR training eliminates the need for expensive physical equipment and facilities traditionally required for hands-on training. This reduction in tangible resources translates to significant cost savings for companies, encompassing expenses related to equipment procurement, maintenance, and facility upkeep. Moreover, by minimizing the need for travel and logistical arrangements associated with traditional training methods, companies can further reduce training expenses and operational downtime.

- Enhanced Learning Outcomes: The immersive nature of VR fosters heightened engagement and retention among trainees, leading to more effective learning outcomes compared to conventional training approaches. By providing a realistic and interactive learning environment, VR enables trainees to actively participate in simulations, apply theoretical knowledge to practical scenarios, and receive immediate feedback on their performance. Consequently, trainees develop a deeper understanding of complex concepts and acquire essential skills more efficiently, contributing to overall competency and proficiency in their roles.

- Remote Training Accessibility: VR technology facilitates remote access to training modules, offering unparalleled flexibility for workers stationed in remote locations, offshore platforms, or other inaccessible areas. By accessing VR training programs through compatible devices, such as VR headsets or desktop applications, employees can participate in training sessions from virtually anywhere with an internet connection. This accessibility not only enhances workforce inclusivity but also minimizes disruptions to operations by eliminating the need for personnel to travel to centralized training facilities.

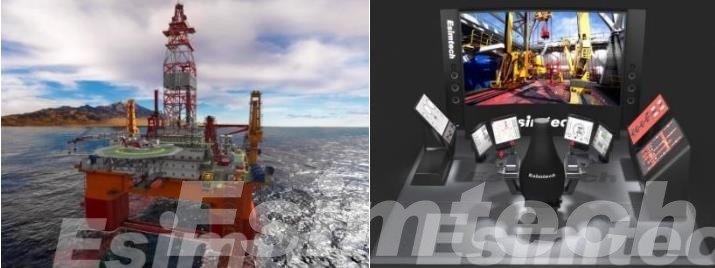

What Esimtech Can Provide You With Its VR Training Technology

Southwest Petroleum University and Chengdu Esimtech Petroleum Equipment Simulation Technology Exploitation Co., Ltd. have jointly developed an exceptional VR training simulation system tailored for the oil and gas sector. This cutting-edge solution is comprehensive and technologically sophisticated, designed to address all training requirements within the industry. Our repertoire includes sought-after VR training simulators like the VR Emergency Training Simulator, Snubbing Simulator, and Device Virtual Assembly. For detailed information on each simulator, please refer to their respective product descriptions, or contact our service team.