Reservoir Simulation Models for Enhanced Oil Recovery (EOR) Techniques

Reservoir simulation models play a crucial role in the oil and gas industry, particularly in enhancing the efficiency of Enhanced Oil Recovery (EOR) techniques. These models offer a virtual framework for representing underground reservoirs, allowing engineers to analyze and simulate different recovery strategies, forecast performance, and make informed decisions. This article explores the fundamentals of reservoir simulation models, including their core components, classifications, workflows, and recent advancements in their application to EOR methods.

What are Reservoir Simulation Models

Reservoir simulation models are mathematical frameworks designed to replicate the behavior of fluids within porous media in petroleum reservoirs. These models combine geological, geophysical, and engineering data to predict the movement of oil, gas, and water under various production conditions. Their primary purpose is to optimize reservoir management by identifying strategies that maximize hydrocarbon recovery while minimizing operational costs and risks.

In Enhanced Oil Recovery (EOR) projects, simulation models are especially vital. They support the design and evaluation of advanced techniques such as chemical flooding, gas injection, and thermal recovery, enabling the extraction of residual oil that conventional methods cannot efficiently produce.

Key Components of Reservoir Simulation

The key components of reservoir simulation can be summarized in the table below:

| Component | Description | Significance |

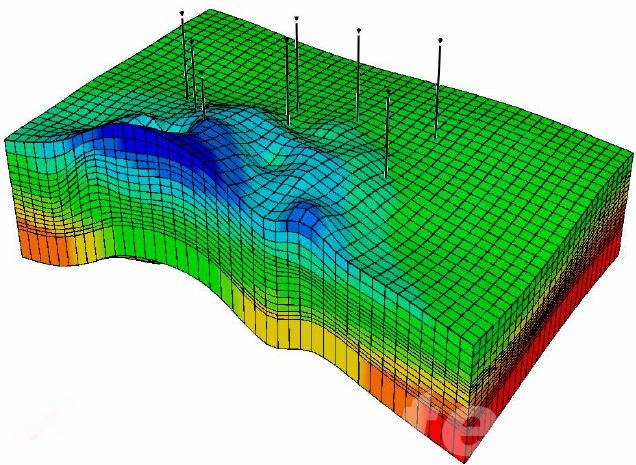

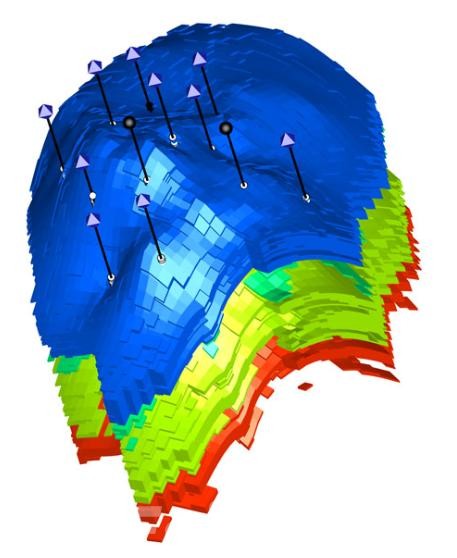

| Reservoir Grid | A 3D grid dividing the reservoir into cells to represent the subsurface. | Determines model resolution and computational efficiency. |

| Reservoir Properties | Includes porosity, permeability, and saturation values for each grid cell. | Defines the reservoir’s capacity to store and transmit fluids. |

| Fluid Properties | Physical and chemical properties of reservoir fluids (e.g., density, viscosity, phase behavior). | Influences fluid flow and recovery processes. |

| Rock-Fluid Interaction | Phenomena such as capillary pressure, relative permeability, and wettability. | Simulates the interaction between fluids and the reservoir rock. |

| Boundary and Initial Conditions | Specifies reservoir limits and initial fluid distribution and pressures. | Establishes the starting point for simulations and constrains model behavior. |

| Numerical Solvers | Algorithms that solve flow equations (e.g., mass, momentum, and energy conservation). | Provides accurate predictions of pressure and fluid movement in the reservoir. |

This structured approach ensures a comprehensive understanding of the reservoir system, enabling precise predictions for EOR techniques.

Types Reservoir of Simulation Models

Reservoir simulation models vary in complexity depending on the specific characteristics of the reservoir and the recovery techniques employed. The main types include:

- Black Oil Models: Black oil models are the simplest type of reservoir simulation, ideal for reservoirs with relatively straightforward fluid compositions. These models assume the presence of three primary phases: oil, water, and gas. They focus on the overall volume and pressure behavior of the reservoir, without accounting for detailed compositional changes in the fluids. Black oil models are typically used in conventional reservoirs and for basic recovery methods.

- Compositional Models: Compositional models are employed when a detailed analysis of the fluid mixture is necessary. These models simulate the behavior of different hydrocarbons in the reservoir, considering their chemical composition and phase changes. They are especially valuable for EOR techniques like CO₂ flooding, where gas miscibility and fluid interactions play a critical role. By accounting for these factors, compositional models provide more accurate predictions of reservoir performance, particularly in gas-injection-based EOR methods.

- Chemical Models: Chemical models are used for reservoirs where enhanced oil recovery techniques involve the injection of chemicals such as polymers, surfactants, or alkaline agents. These models simulate the changes in fluid properties and rock-fluid interactions caused by the chemicals, helping optimize recovery methods like polymer flooding or surfactant-based methods. Chemical models can also be used to predict the impact of chemical flooding on reservoir permeability and wettability.

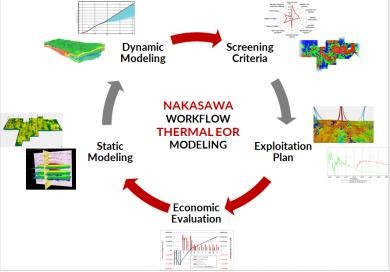

- Thermal Models: Thermal models are specifically developed for reservoirs where heat is a key factor in the recovery process. These models simulate the impact of thermal recovery methods, such as steam injection (steam flooding) or in-situ combustion, which help reduce oil viscosity and enhance flow rates. Thermal models take into account temperature distribution and the changes in fluid properties that occur as a result of heat.

Each type of reservoir simulation model serves a specific purpose and is selected based on the characteristics of the reservoir and the EOR method being applied.

Reservoir Simulation Workflow for EOR Applications

The reservoir simulation workflow for Enhanced Oil Recovery (EOR) applications involves a series of systematic steps to ensure accurate modeling and effective decision-making. The workflow is as follows:

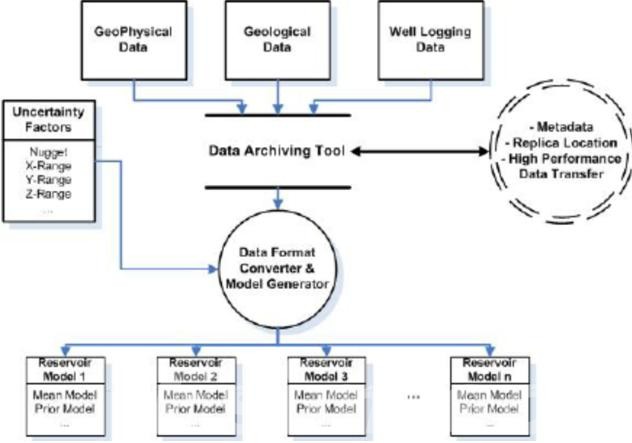

- Data Collection and Integration:

The first step in the process involves collecting all relevant data, including geological, geophysical, petrophysical, and production information. This data is then integrated into the simulation model to ensure an accurate representation of the reservoir’s characteristics, such as rock types, fluid properties, and historical production data.

- Model Construction:

A digital grid or mesh is created to represent the reservoir, dividing it into cells. Each cell is assigned key properties like porosity, permeability, and fluid saturation. Depending on the selected EOR method (e.g., CO₂ injection or thermal recovery), the appropriate model type—such as black oil, compositional, or thermal—is chosen to simulate the reservoir’s behavior under varying conditions.

- History Matching:

History matching is a critical step in refining the model to align with actual field data. This process involves adjusting the model by comparing its predicted outcomes with historical production and pressure data. The objective is to calibrate the model so that it accurately reflects past reservoir performance, providing a solid foundation for future simulations.

- EOR Scenario Simulation:

Once the model is calibrated, various EOR strategies are tested through simulations. These may include techniques such as gas or chemical injection, water flooding, or thermal recovery. The simulations assess the impact of different variables—such as injection rates, fluid compositions, and operational strategies—on recovery efficiency and overall reservoir performance.

- Optimization and Forecasting:

The simulation results are carefully analyzed to determine the most effective EOR strategy. Optimization techniques, such as sensitivity analysis and design of experiments, are used to fine-tune key parameters and maximize recovery. The model is then leveraged to forecast future production, estimating how the reservoir will perform under the chosen EOR scenario over time.

- Implementation and Monitoring:

Once the optimal EOR method is selected, it is put into practice in the field. The simulation model is regularly updated with real-time data from monitoring systems, enabling adjustments to the recovery process based on actual reservoir performance. This ongoing monitoring ensures that the EOR techniques remain efficient and adaptable throughout the project’s lifespan.

By following this structured workflow, reservoir simulation enables more informed decision-making, better management of resources, and more effective deployment of EOR techniques.

Advances in Reservoir Simulation for EOR

Recent advancements in reservoir simulation have greatly improved the accuracy, speed, and effectiveness of Enhanced Oil Recovery (EOR) techniques. Key developments include:

- High-Performance Computing (HPC): The application of HPC enables the simulation of large, complex reservoirs using fine-scale grids and detailed physical models, dramatically reducing the computational time needed for simulations. This capability enhances prediction accuracy and accelerates decision-making.

- Real-Time Simulation and Monitoring: By integrating real-time data from digital oilfields, simulation models can be continuously updated, providing improved monitoring of EOR operations. This facilitates faster adjustments, ensuring the recovery process is continuously optimized.

- Machine Learning and AI: Artificial intelligence and machine learning algorithms are increasingly integrated into reservoir simulation to enhance history matching, automate optimization processes, and predict reservoir behavior under various EOR scenarios. These technologies can identify patterns in data that would be difficult for humans to detect.

- Uncertainty Quantification: Advanced uncertainty quantification techniques enable modelers to address unknown variables in reservoir characteristics, enhancing the reliability of predictions and improving risk management during EOR planning.

- Coupled Multiphysics Models: Contemporary simulations now integrate multiple physical processes, such as fluid flow, geomechanics, and thermal effects, into a unified framework. This coupled approach offers a more accurate and comprehensive understanding of reservoir dynamics, particularly for EOR techniques like steam injection or CO₂ flooding.

These innovations are transforming how EOR projects are designed and executed, increasing both efficiency and recovery rates.

Reservoir simulation models are vital for optimizing Enhanced Oil Recovery (EOR) techniques, improving recovery rates, and reducing costs. Advancements in computing, machine learning, and real-time monitoring are enhancing their accuracy and efficiency, making them a key tool for more sustainable and effective EOR operations.