Reservoir Simulation in the Oil and Gas Industry

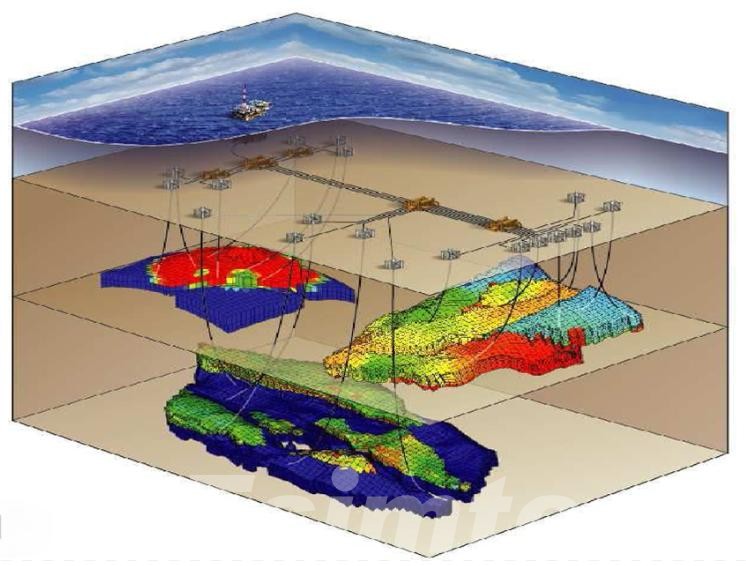

Reservoir simulation is a crucial tool in the oil and gas industry, providing detailed models of subsurface reservoirs to predict their behavior over time. This process uses mathematical models to represent the physical and chemical interactions within a reservoir, aiding in decision-making for exploration, development, and production. By leveraging reservoir simulation, companies can optimize resource extraction, reduce costs, and improve efficiency.

Importance of Reservoir Simulation

- Optimizing Production: Reservoir simulation helps in understanding the most efficient ways to extract hydrocarbons, maximizing recovery and extending the life of the reservoir.

- Risk Management: By predicting reservoir behavior under various scenarios, simulation aids in assessing and mitigating risks associated with drilling and production.

- Economic Planning: Accurate simulations provide valuable data for economic forecasting, helping companies make informed investment decisions.

- Environmental Protection: Simulation models help in planning extraction processes that minimize environmental impact, ensuring sustainable operations.

Key Components of Reservoir Simulation

Reservoir simulation is a complex process that integrates various data types and models to predict the behavior of subsurface reservoirs. Understanding its key components is essential for building accurate and reliable simulation models.

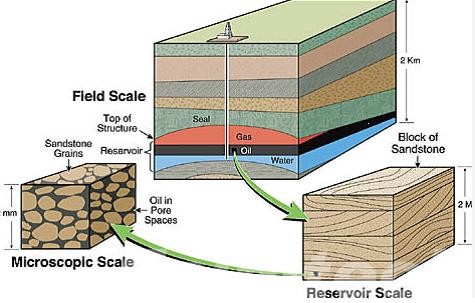

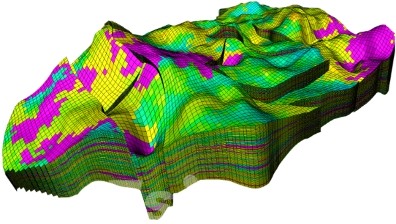

1. Geological Model

The geological model is the foundation of reservoir simulation, providing a detailed representation of the reservoir’s physical structure and characteristics.

- Structure: Defines the geometry of the reservoir, including faults, folds, and other structural features.

- Lithology: Describes the types and distributions of rock within the reservoir.

- Reservoir Zones: Identifies different layers or zones within the reservoir, each with distinct properties.

2. Petrophysical Model

The petrophysical model describes the physical properties of the reservoir rocks that influence fluid flow and storage.

- Porosity: Measures the proportion of void spaces in the rock, which affects its ability to store fluids.

- Permeability: Indicates the rock’s ability to transmit fluids through its pore network.

- Saturation: Refers to the distribution of fluids (oil, water, gas) within the pore spaces.

- Capillary Pressure: Describes the pressure required to move fluids through the rock’s pore network.

3. Fluid Model

The fluid model characterizes the properties and behavior of the fluids present in the reservoir, including oil, gas, and water.

- PVT Properties: Pressure-Volume-Temperature relationships for the reservoir fluids, essential for understanding how they will behave under different conditions.

- Phase Behavior: Describes how the fluids interact and transition between phases (e.g., from liquid to gas) within the reservoir.

- Viscosity and Density: Key properties that affect fluid flow and pressure distribution within the reservoir.

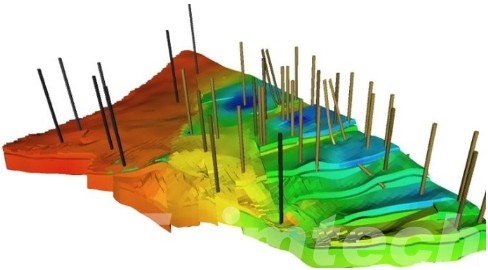

4. Dynamic Model

The dynamic model simulates the movement and interaction of fluids within the reservoir over time, considering the effects of production activities and natural processes.

- Flow Equations: Mathematical equations that describe the flow of fluids through the reservoir’s porous media.

- Boundary Conditions: Define the external limits of the reservoir model, including pressure and flow constraints.

- Initial Conditions: The starting state of the reservoir, including initial fluid distribution and pressure.

- Well Models: Represent the locations and characteristics of production and injection wells, including their impact on fluid flow and pressure distribution.

5. Reservoir Management Strategies

The simulation model also integrates various management strategies to optimize reservoir performance.

- Production Planning: Determines the optimal production rates and schedules to maximize recovery.

- Enhanced Oil Recovery (EOR) Techniques: Evaluates the effectiveness of EOR methods such as water flooding, gas injection, and chemical injection.

- Reservoir Monitoring: Incorporates real-time data and historical production data to update the model and refine predictions.

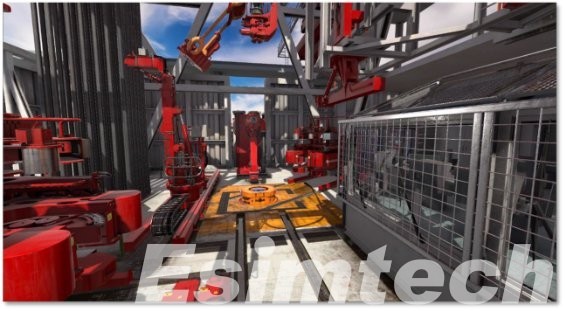

6. Computational Tools and Software

Advanced software and computational tools are used to build, run, and analyze reservoir simulations.

- Simulation Software: Specialized oil and gas software such as ECLIPSE, CMG, and PETREL is used to create and run simulation models.

- High-Performance Computing (HPC): Utilizes powerful computing resources to handle the complex calculations required for large and detailed reservoir models.

- Visualization Tools: Visual Oil and gas simulation tools help in interpreting the simulation results through 3D models, graphs, and charts, making it easier to understand and communicate findings.

Types of Reservoir Simulation Models

This chart provides a concise overview of the different types of reservoir simulation models, highlighting their descriptions, applications, advantages, and limitations.

| Model Type | Description | Applications | Advantages | Limitations |

| Black Oil Model | Simplified model assuming immiscible oil and gas phases with constant properties. | Conventional oil reservoirs. Primary recovery methods. | Simple and fast. Requires fewer data inputs. | Limited accuracy for complex fluid interactions. Not suitable for gas condensate reservoirs. |

| Compositional Model | Detailed model that considers changing fluid compositions over time. | Gas condensate reservoirs. Volatile oil reservoirs. | Accurate for complex fluid systems. Accounts for compositional changes. | Computationally intensive. Requires detailed fluid data. |

| Thermal Model | Model that incorporates the effects of temperature changes on fluid behavior. | Steam injection. Thermal EOR methods. | Accurate for thermal recovery processes. – Captures temperature effects. | High computational demands. Complex to set up and calibrate. |

| Chemical Model | Simulates the interaction of injected chemicals with reservoir fluids and rock. | Chemical EOR methods (e.g., polymer flooding, surfactants). | Enhances recovery prediction for chemical EOR. | Requires detailed chemical properties and interactions. Can be complex and time-consuming. |

| Dual-Porosity Model | Models reservoirs with naturally fractured systems, treating matrix and fractures separately. | Naturally fractured reservoirs. Carbonate reservoirs. | Better representation of fractured systems. | Complex to implement and calibrate. Requires detailed fracture data. |

Key Steps in Reservoir Simulation

These steps provide a structured approach to reservoir simulation, ensuring that models are accurate, useful, and aligned with real-world conditions. Each step builds on the previous one to enhance the understanding of reservoir behavior and optimize hydrocarbon recovery.

| Step | Description | Key Activities |

| 1. Data Collection | Gathering all necessary data to build the simulation model. | Collect geological, petrophysical, and fluid data.Acquire historical production and well data.Obtain seismic and core sample data. |

| 2. Model Building | Constructing the initial models based on collected data to represent the reservoir’s characteristics. | Develop geological and petrophysical models.Create fluid and dynamic models.Define reservoir boundaries and initial conditions. |

| 3. History Matching | Calibrating the model by adjusting parameters to match historical production data and reservoir behavior. | Compare simulation results with historical production data.Adjust model parameters to improve accuracy.Validate the model against observed data. |

| 4. Forecasting | Running the calibrated model to predict future reservoir performance under various production scenarios. | Simulate different production strategies and scenarios.Analyze the impact of changes in operational parameters.Estimate future production rates and reservoir conditions. |

| 5. Optimization | Using simulation results to refine and optimize reservoir management strategies for enhanced performance. | Identify optimal well placement and production rates.Evaluate the effectiveness of enhanced oil recovery (EOR) methods.Adjust operational plans based on simulation insights. |

| 6. Sensitivity Analysis | Assessing the impact of uncertainties and variations in input parameters on simulation outcomes. | Perform sensitivity analysis to identify critical parameters.Evaluate how changes in inputs affect results.Use findings to improve decision-making and risk management. |

| 7. Integration and Updating | Continuously integrating new data and updating the model to reflect changes in reservoir conditions and operations. | Incorporate real-time data and new observations.Update the model to reflect changes in reservoir behavior.Ensure ongoing accuracy and relevance of the simulation. |

| 8. Reporting and Decision Making | Communicating simulation results and insights to stakeholders for informed decision-making. | Prepare detailed reports and visualizations.Present findings to decision-makers.Use simulation results to support strategic planning and operational decisions. |

Challenges in Reservoir Simulation

1. Complex Reservoir Geometries

- Challenge: Real-world reservoirs exhibit complex geometries and heterogeneities that are difficult to accurately represent in models.

- Impact: Simplifications or inaccuracies in geometric representation can lead to errors in predicting fluid flow and reservoir performance.

2. Data Quality and Availability

- Challenge: Reservoir simulations rely on diverse data sources (e.g., seismic, well logs, production data) that may be incomplete, noisy, or inconsistent.

- Impact: Poor data quality can compromise model accuracy and reliability, leading to suboptimal decision-making.

3. High Computational Costs

- Challenge: Simulating large and complex reservoirs requires significant computational resources, which can be expensive and time-consuming.

- Impact: High computational demands can limit the resolution of models and the frequency of simulation updates, reducing the overall effectiveness of the simulations.

4. Uncertainty Quantification

- Challenge: Reservoir parameters (e.g., porosity, permeability) and future conditions (e.g., production rates, market demand) are inherently uncertain.

- Impact: Managing and quantifying these uncertainties is crucial for reliable predictions and risk assessment but is challenging due to the complex nature of reservoirs.

5. Multiphase Flow Dynamics

Challenge: Simulating the behavior of multiple fluid phases (oil, gas, water) within the reservoir adds significant complexity.

Impact: Accurate modeling of multiphase flow is essential for predicting reservoir performance but is challenging due to the complex interactions between phases.

6. Scale-Up Issues

Challenge: Laboratory or small-scale model results often need to be scaled up to apply to full-field simulations, which can introduce errors.

Impact: Ensuring that scale effects are appropriately accounted for is critical for accurate reservoir performance predictions.

7. Dynamic Reservoir Behavior

Challenge: Reservoir conditions change over time due to production activities and natural processes, requiring continuous updates to models.

Impact: Capturing dynamic behavior accurately is challenging and essential for effective reservoir management and optimization.

8. Geomechanical Effects

- Challenge: Reservoir depletion and fluid injection can induce stress changes in the surrounding rock, impacting reservoir performance.

- Impact: Ignoring geomechanical effects can lead to inaccurate predictions of subsidence, compaction, and potential reservoir damage.

9. Integration of Diverse Data Types

- Challenge: Integrating various data types (e.g., geological, geophysical, petrophysical) into a coherent reservoir model is complex.

- Impact: Effective integration is essential for building accurate and comprehensive models but requires sophisticated data assimilation techniques.

10. Environmental and Regulatory Concerns

- Challenge: Increasing regulatory requirements and environmental considerations add complexity to reservoir simulation and management.

- Impact: Ensuring compliance with regulations and minimizing environmental impact are essential but add additional layers of complexity to simulations.

Potential Solutions

| Challenge | Potential Solutions |

| Complex Reservoir Geometries | Advanced modeling techniques to capture complex geometries and heterogeneities |

| Data Quality and Availability | Improved data acquisition technologies and processing methods |

| High Computational Costs | High-performance computing (HPC) and cloud-based solutions |

| Uncertainty Quantification | Machine learning and AI for optimizing simulations and handling uncertainty |

| Multiphase Flow Dynamics | Enhanced numerical methods and specialized software for multiphase flow |

| Scale-Up Issues | Advanced upscaling techniques to account for scale effects |

| Dynamic Reservoir Behavior | Real-time data assimilation techniques for continuous model updates |

| Geomechanical Effects | Integration of geomechanical modeling to account for stress changes |

| Integration of Diverse Data Types | Sophisticated data assimilation techniques to integrate various data types |

| Environmental and Regulatory Concerns | Incorporation of sustainability and environmental impact assessments into simulation workflows |

| Collaborative and Open-Source Platforms | Use of collaborative platforms and open-source software for knowledge sharing and innovation |

| Sustainability and Environmental Metrics | Integration of sustainability metrics to ensure regulatory compliance and minimize ecological impact |