ESIM-PDS9B Portable Drilling Well Control Simulation Training System

- Calculate WOB during drilling, calculate pump pressure after pump is started, and calculate the fluctuating pressure during tripping.

- Simulate hard shut-in process and soft shut-in process.

- Simulate shut-in with blow-out preventer inside drill string

- Calculate shut-in drill pipe pressure of the drill string with non-return valve.

- Simulate the pressure change of gas migration.

- Reflect the fluctuating pressure when pipe coupling passing through the closed annular ram.

1.System Introduction

The portable well control simulation system is developed by Chengdu Esimtech Petroleum Equipment Simulation Technology Co., Ltd, specializing in drilling simulation training, featuring convenient carrying and perfect functions. The system complies with the standards of IADC and IWCF.

The system combines petroleum engineering, computer technology, virtual reality and computer simulation technology. It is mainly used for training of new employees, drillers and assistant drillers, drilling technicians, drilling foreman, drilling supervisors and so on.

The system uses mathematical models to simulate various working conditions and parameters such as pressure, torque, drilling rate and displacement, etc. in petroleum engineering operations, accurately reacting the relationship between these physical parameters to achieve the same effect as actual drilling operations. It can flexibly set drilling parameters, such as well bore configuration, formation and equipment parameters, to make the training more flexible and targeted. The software system can realize realistic simulation of rig operations with non-sequence structure to get the system closer to that actual. Virtual reality technology makes up a vivid perceptual environment, and 3D animation is synchronic with the real operation , delivering an immersive

experience in combination with simulation sound effect.

The system consists of portable hardware, graphics system and supporting software. Hardware system is designed in accordance with industrial standards, and the data acquisition system and control system are composed of embedded devices to ensure the reliability of the equipment to the greatest extend. Its input cost and maintenance cost are low with risk-free security.

2.System Component

(1) Main Hardware devices

The system mainly contains driller console, portable top drive console, portable BOP console, and portable choke console. The consoles are made by aluminum alloy, with the advantage of small size, and easy to carry.

Figure 1 System layout

a) Portable driller console

Portable driller console is as shown in figure 2. The control and displaying contents are the same as real driller console. It can simulate drawworks raising and lowing, pump speed adjusting, rotary rate adjusting, etc. This panel can display parameters such as pump speed, pump pressure etc. at real time.

Figure 2 Portable driller console

b) Portable top drive console

As shown in figure 3, portable top drive console can simulate various operations and logic controls, such as adjusting top drive speed rate, IBOP, turret lock, links rotation, links tilting, clamp, operation (drill, spin, torque), direction (FWD, Stop, REV). Besides, it can display the data of torque and speed rate in real time.

Figure 3 Portable top drive console

c) Portable BOP console

Portable BOP console is as shown in figure 4. The control and parameter display are the same as real products. The parameter display is the same as real device. Portable BOP console simulates one annular, two pipe rams and one blind ram. Besides, it can simulate the close and lineup of kill line and choke line.

Figure 4 Portable BOP console

d) Portable choke console

Portable choke console is as shown in figure 5. Parameters such as casing pressure, drill pipe pressure, kill manifold pressure, pump speed, total strokes, choke position, etc. are displayed on this panel. There is also choke position adjusting knob on this panel.

Figure 5 Portable choke console

(2) System Software

1) Master Control Software

a) Platform software module

Display drilling parameters at real time, able to set parameter alarm, and simulate the operation and display of surface circulation system.

b) Instructor station software module

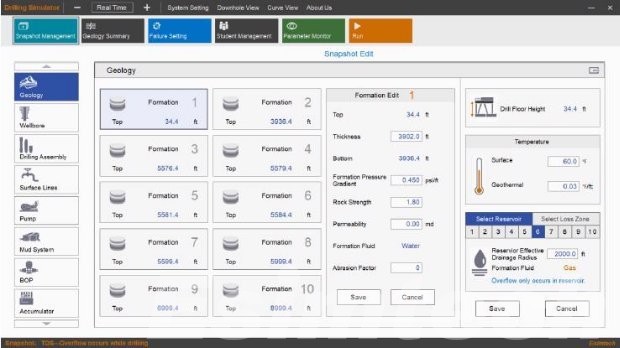

Able to set and modify various parameters, such as formation parameter, well structure, drilling string assembly, pump parameters, mud system, surface manifold, BOP, etc. can display drilling parameters at real time, such as WOB, ROP, footage, pit gain/loss, return flow, pump speed, flow rate, total strokes, kelly in, etc. can set problems, parameter units, languages. Can control the simulation speed, and can pause and save the exercise and also resume the saved exercise.

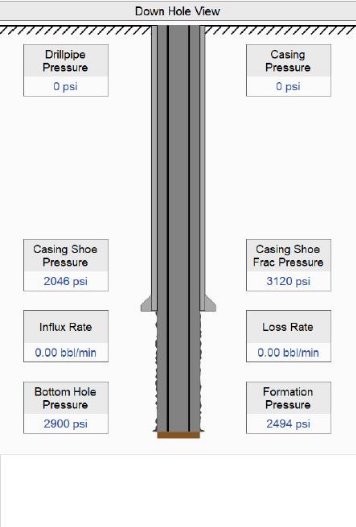

c) Well control software module

Able to realize well control operation, showing well control parameters such as casing pressure, drill pipe pressure, choke position, casing shoe pressure, BHP, etc. at real time. Can save and print various parameter curves such as drill pipe pressure, casing pressure, pit gain/loss, BHP, formation pressure, etc.

d) Sound effect control module software

Able to simulate the noises of pumps, drawworks, rotary table, etc. on drilling site.

e) System diagnosing module

Able to diagnose the hardware state through this module.

f) Student management and automatic scoring software module

2) Graphics Software

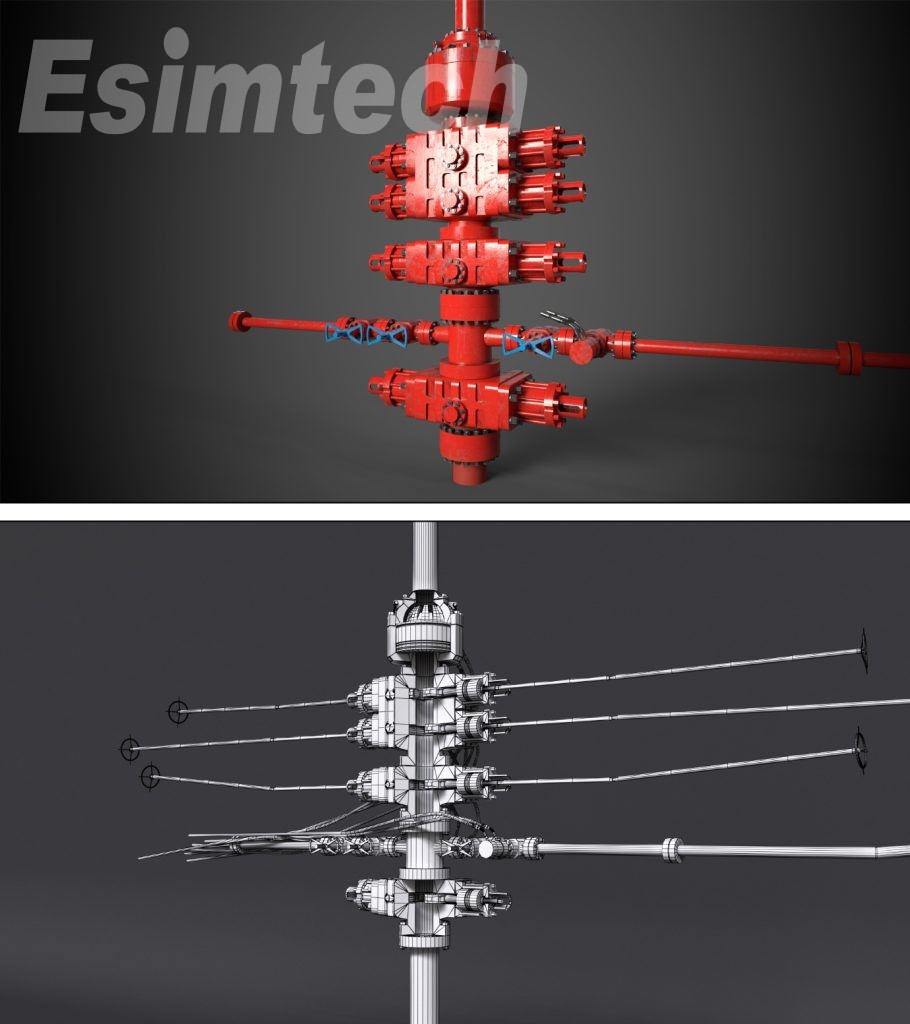

a) Top drive-based 3D scene displaying software module

b) Rotary table and Kelly based 3D scene displaying software module

3. System Configuration

|

SN |

Name |

Unit |

Q’ty |

Config. |

|

1 |

Portable driller’s console |

Unit |

1 |

Standard |

|

2 |

Portable top drive console |

Unit |

1 |

Optional |

|

3 |

Portable BOP console |

Unit |

1 |

Optional |

|

4 |

Portable choke console |

Unit |

1 |

Standard |

|

5 |

Portable computer (CPU: i7; discrete graphic card) |

Unit |

1 |

Standard |

|

6 |

Touch screen |

Unit |

1 |

Standard |

|

7 |

Esimtech portable drilling simulator technology software |

Set |

1 |

Standard |

|

8 |

Esimtech portable drilling simulator graphics software |

Set |

1 |

Standard |

4. Software Functions

(1) Sound effect

The simulated noises of the simulator are the same as that on real site, such when the drilling equipment is running, collision, speed up and down.

(2) Simulator function

The simulator is portable, the size, weight, and quantity all suitable for instructor to take out for training. The simulator can provide training for different posts such as driller, driller assistant, drilling crew technician, drilling crew leader, drilling supervisor, etc. The simulation training can enable trainee to master the skills of soft/ hard shut-in, and conventional/unconventional well killing.

The simulator adopts mathematical models to simulate various working condition and parameters in petroleum engineering drilling operation, such as pressure, torque, ROP, flow rate, etc. and can reflect the relations between these parameters, which realizes the same effect as in real drilling operation.

The simulator enables user to set various drilling parameters, such as drilling string assembly, well structure, formation parameters, device parameters, etc. which makes the training more flexible and targeted. The software program adopts non-sequence structure, which can simulate various rig operation, and closer to reality. Virtual reality technology makes up a vivid perceptual environment, and 3D animation is synchronic with the real operation.

The simulator is made according to industrial standard, Data acquisition and control system is completed by industrial controller, which ensures the reliability of the system.

(3) System features

1) The system has non-sequence structure, which has no operation sequence limit to trainees. It simulates the model and functions of real drill rig. Operator can operate the system in any way just as operating real drill rig.

2) The system has the function of provide various operations by uploading one well condition snapshot. With one appropriate well condition snapshot, student can be trained of series of operations of tripping in and out, drilling, kick, shutting in and well killing.

3) Parameters can be set freely. Instructor can set various parameters, such as drilling string make up, formation parameters, mud parameters, devices parameters, etc. Instructor can also customize the parameters based on actual well condition and devices, so that the training is just like operating on a real well.

4) The system provides problem setting function. Instructor can set various device fault or down-hole problem during student operating. And students can judge the problems by observing the change of parameters. Instructor can set problems or faults such as pipe leakage, nozzle plug, nozzle erosion, choke valve erosion, pump fault, BOP fault, etc.

5) The system provides downhole model setting function. The instructor can set the speed of gas migration, whether there is multi-kick, choke valve type, whether the gas can move into the drill pipe.

6) The system can simulate multi-kick, and evaluate the kick handling operation.

7) They system provides the automatic regulation function of the choke valve opening position during well killing.

8) The system can conduct the pressure loss test of the whole circulation path.

9) The system provides speed control function. Instructor can increase and reduce the speed of the exercise when necessary.

10) The system also has alarm setting function. Trainees can set various parameter limits. When parameters exceed these limits, the system will launch an alarm. The launching and stopping of alarm comply with student’s operation, working condition and graphics.

11) 3D animation simulates site visual environment. Animation can present down-hole scene, devices motion and device working theories. The animation can also display the relationship, standing position and operation rules of different working post in drilling. The scene can be displayed on the screen by shifting scenes and in split screen way, such as ranking platform, drilling fluid flow line, various curves and real time data, etc.

12) The system has lifelike scene sound effect. The system can simulate various sounds in real site. The launching and stopping of sounds comply with student’s operation, working condition and graphics.

13) The system can present the manifold layout in the form of the graphic software, and displays the simulated manifold path in the form of flowing.

14) The system can display the changing trend of important parameters in the form of curves, so that students can judge down-hole condition and problem through the curves.

15) It has curves playback function, which can replay the parameter changes during students’ peration in the form of curves for students review.

16) The system has flexible training control function. It can freeze, save and resume exercise at any time.

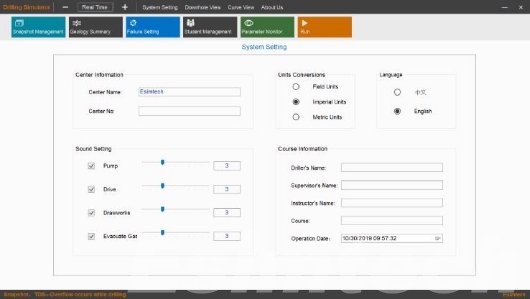

17) The measurement unit can be in metric and also English.

18) The system has two languages English and Chinese and can be switched at any time.

19) The system has automatic scoring function. It can give out score to student’s operation,and also the point deduction reasons.

20) It has completed student management function.

(4) Training Items

(1) Shutting in operation

a) Shutting in operation when kick occurs during drilling

b) Shutting in operation when kick occurs during tripping out drill pipe

c) Tripping in and out operation after shutting in operation when kick occurs during tripping out

d) Shutting in operation when kick occurs during tripping out

e) Shutting in operation when kick occurring in barren hole

(2) Well killing operation

a) Driller’s method of well killing

b) Engineer’s method of well killing

c) Volumetric method of well killing

(5) System features

(1) During drilling, the system can simulate calculating WOB. After pump is started, the system can calculate pump pressure. During tripping, the system can calculate the fluctuating pressure.

(2) The system can simulate hard shut-in process and soft shut-in process.

(3) The system can simulate shut-in with IBOP in drill string (such as cock, back pressure valve.)

(4) After shut-in, the system can calculate shut-in drill pipe pressure of the drill string with non-return valve.

(5) The system can simulate the pressure change of gas migration.

(6) The system can calculate the friction when drill pipe or pipe coupling passing through the closed annular and pipe ram.

(7) The system can reflect the fluctuating pressure when pipe coupling passing through the closed annular ram.

5.Technical Parameters and Operation Condition

(1) Technical Parameters

a) Power Supply:110~220v/50~60Hz AC

b) Power consumption: 0.3kw

(2) Operation Condition

a) Operating temperature: 0-30degrees Celsius

b) Relative humidity: < 90%

6. Program Interface

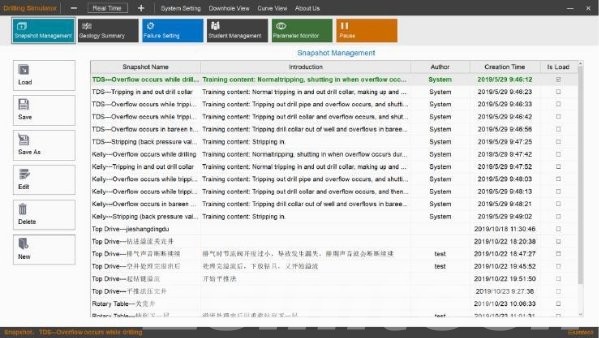

Figure 7 Student screen

Figure 8 Instructor screen

Figure 9 Parameter setting screen

Figure 10 System setting screen

Figure 11 Downhole view

Figure 12 Graphics screen— Kelly

Figure 13 Graphics screen— Top drive

The simulator is certificated by IADC & IWCF.

Why Choose Us?

- Cutomization

- Customized software and hardware

- Preciseness

- Precise mathematical and physical model

- Reliability

- Stable and reliable software and hardware