ESIM-PSS2 Portable Snubbing Simulator

- Cutomization

- Customized software and hardware

- Preciseness

- Precise mathematical and physical model

- Reliability

- Stable and reliable software and hardware

Introduction

Portable snubbing simulation training system is developed by Southwest Petroleum University and Chengdu Esimtech Petroleum Equipment Simulation Technology Exploitation Co.Ltd.It is a system used to provides simulation training of snubbing operations-running and pulling string.It has the advantages such as easy to take away,and with completed functions

Portable snubbing simulation training system is developed by combining petroleum engineering, computer technology, and virtual reality technologies. It can simulate the operations such as running and pulling tubing and other tools with pressure. It can be used to training new workers, crew leader, operation supervisor, etc. Through the training provided by this system, students can master the basic technological process of running and pulling out string with pressure.

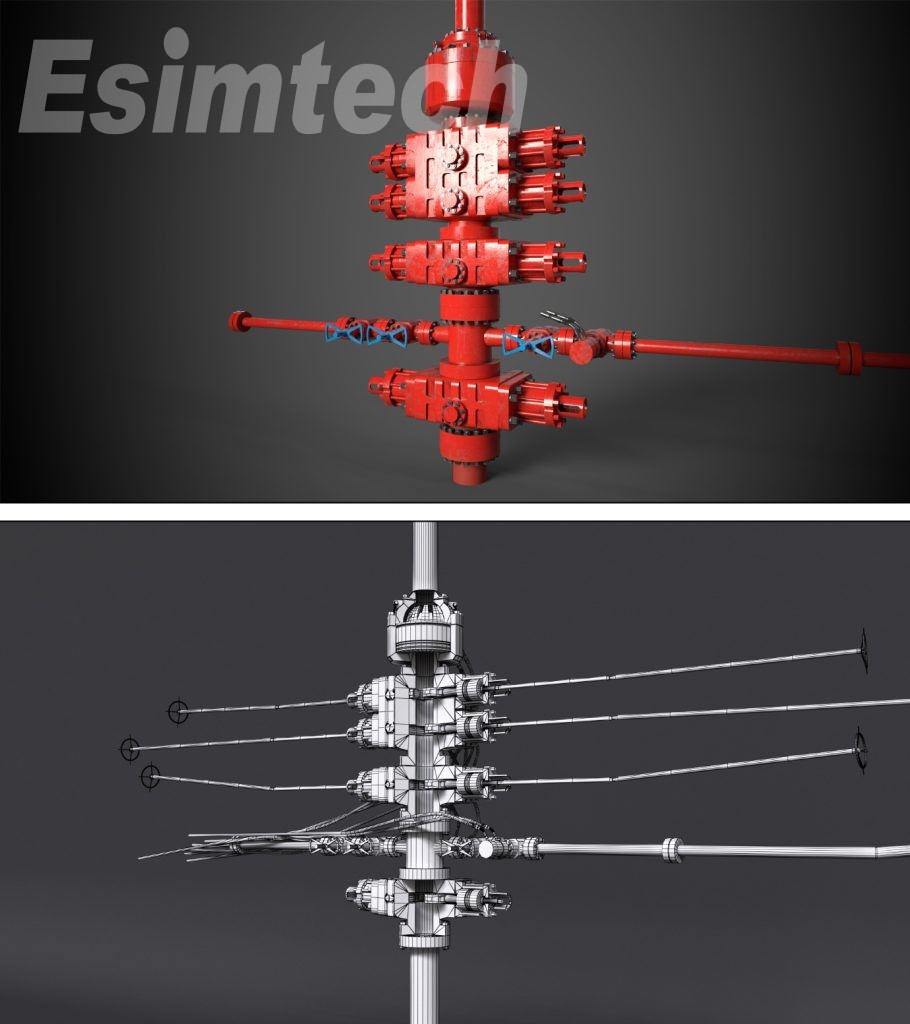

The system adopts quantity of mathematical models to simulate various parameters and physical relationship between them in snubbing operation, such as balance point, pressure, rate, etc. to reach the actual effect of real snubbing operation. Real time 3D animation can be displayed through single channel projecting system, which makes students clearer about snubbing operation.

This system is composed of snubbing driller control console, graphics system and accessory software. Hardware system is designed according to industrial standard. Data acquisition and control system is made up by PLC, which ensures the reliability of the system. The system has low input cost and maintenance cost and no security risk.

2. System Component

2.1 System Hardware

The system is available when the snubbing driller console and computer is connected to any display output. It can simulate the motion of lifting machine, slips, BOP rams, etc. and displays the lifting pressure, BOP ram pressures, etc.

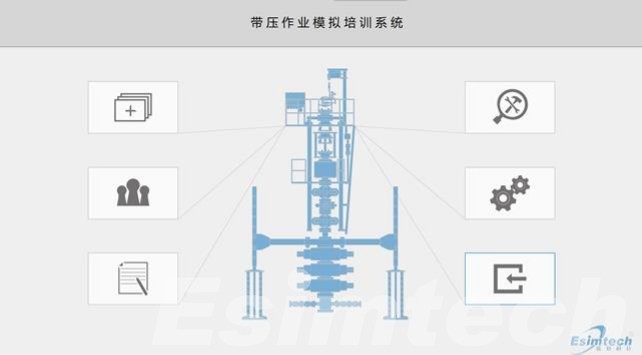

Figure 1 System layout

2.2 System Software

2.2.1 Master control software

-

Platform software module

-

Instructor console software module

-

Well condition data recording and analyzing module

-

Running and pulling tubing software module

-

System self-checking module

-

Student managing and automatic scoring software module

2.2.2 Graphics software

1. Hydraulic drive based snubbing 3D scene display software module

2.3 System standard configuration

|

SN |

Name |

Unit |

Q’ty |

|

1 |

Portable snubbing control panel |

Unit |

1 |

|

2 |

Laptop (CPU:i7;Graphics card: Discrete graphics card) |

Unit |

1 |

|

3 |

Esimtech portable snubbing operation software |

Set |

1 |

3. System Function

3.1 Function and Feature

1. Parameter display: system oil pressure, BOP ram pressure, balance/ bleed valve, casing pressure, well depth, tubing shoe location, lifting board height, etc.

2. It has flexible parameter setting function. Instructor can set various parameters freely, such as well depth, casing pressure, tubing parameter, etc. Instructor can customize parameters based on real well condition and real equipment condition, which can make the training more authentic.

3. 3D animation provides the real site visualization. The animation can display the snubbing rig floor scene, BOP motion and working theories. The system can display different scenes through shifting and splitting screen display, such as driller console perspective, BOP perspective, slips perspective, etc.

4. The system can score students’ operation automatically. It can provide scores and point deducting reasons according to students’ operation procedure and skill.

5. It has completed students managing function. It can manage students’ information, operation project, scores, etc.

3.2 Training Project

-

Calculating balance point

-

Running and pulling tubing:

(1) Pulling string above high-pressure balance point

(2) Pulling string below high-pressure balance point

(3) Pulling string above low-pressure balance point

(4) Pulling string below low-pressure balance point

(5) Running string above high-pressure balance point

(6) Running string below high-pressure balance point

(7) Running string above low-pressure balance point

(8) Running string below low-pressure balance point

Technical Parameters and Operational Environment

4.1 Technical Parameters

(1) Powersupply:220V/50Hz AC

(2) Power consumption: <1000W

(3) Resolution: 1920*1080

4.2 Operational Environment

(1) Working temperature: 0℃~30℃

(2) Relative humidity: <90%

Program Interfaces

Figure 2 Master control software interface

Figure 3 Program running interface

Figure 4 Software interfaces

System Features

- Actual 3D interactive animation

- Lifelike environment noises and voice prompt

- Strict mathematic simulation, conforming to real technology demands

- Systematic and complete training content, flexible project configuration

- Intelligent scoring, fair assessment

- Advanced software, friendly interface

- Industrial PLC control with high stability

Components

Portable snubbing control panel

F&Q

- What new petroleum simulations and features are you working on?

Esimtech has been committed in study and developing petroleum engineering simulation training systems for about 30 years, and has a series of independent intellectual property rights. Our simulators are widely used in many training companies with good feedback. To keep pace with the international standard and demand, Esimtech is now studying and developing an MPD simulator, where some achievement has been reached.

- Do you have any certifications?

Esimtech drilling and well control simulator has been approved by IWCF and IADC.

Since its establishment, Esimtech has obtained a series of independent intellectual property rights, including invention patents in China and abroad.

Esimtech was granted as “High-tech Enterprise”, and has been awarded the third prize of “Science and Technology Progress”.

Esimtech has also obtained the certificates of ISO 9001, ISO14001, and ISO45001.

- Do you have simulators simulating offshore drilling platforms?

Esimtech provides drilling and well control simulators with offshore platform simulation.

- Is there a complete instruction for use if I ordered?

There will be completely operational instruction and maintenance instruction along with the package.