ESIM-FTD1 Top Drive Simulator

- Cutomization

- Customized software and hardware

- Preciseness

- Precise mathematical and physical model

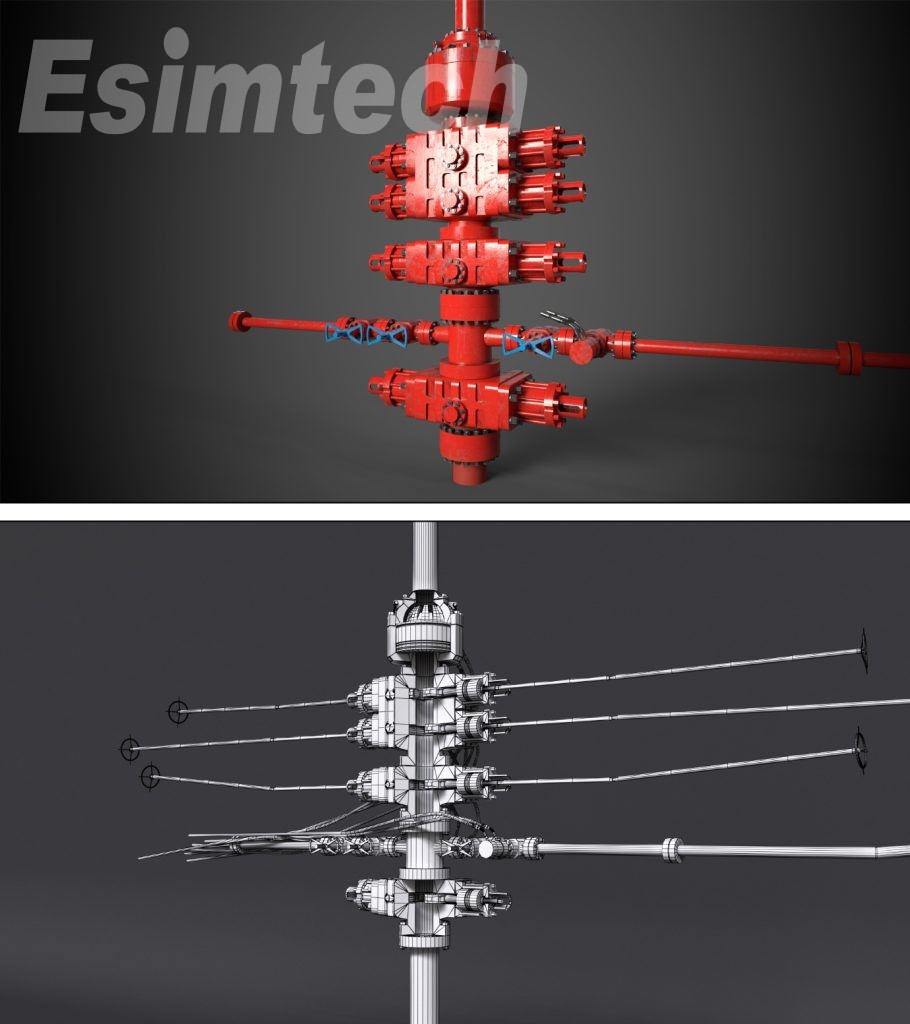

- Reality

- Highly realistic 3D scene display

Introduction

Top drive simulation training system is constructed according to advanced training mode and training method, focusing on the cultivation of practical operation ability.

The top drive simulation training system is developed aiming for training the operation of top drive device.Itcan provide training items of all top drive operation and common accident handling.Itcan be used for training fordriller/driller assistant, technicians, and drilling team leader. Through training with the system, trainee can master the operation method of top drive and handling skill of common accidents.

The system adopts various mathematical models to simulation the working principle of top drive, reflecting the changing rule of various parameters. Event-driven simulation technology can simulate various operation of the device which make the training closer to reality. Accidents pre-set technology simulating common accidents and device fault, enables instructor to insert the accidents or faults at any time. Trainee then can judge the phenomenon then make correct actions. This improves their skill of judging and handling accidents. Virtual reality technology constructs a perceptual environment; 3D animation synchronic with operation displays the site scene, combining with vivid sound effect. All of those makes up an immersive training environment.

Top drive simulation practice system is composed of a few top drive simulation systems. Each simulation system consists of top drive console, drawworks handle, computer and two touch screens. Top drive console is made according to the top drive produced by Beijing Petroleum Machinery Factory. The controls layout, operation method, parameter display is the same as the real product. Hardware device is constructed by industrial PLC, which ensures the reliability of the system. The system has also the advantage of low input and maintenance cost without security risks.

System component

2.1 Major hardware

-

1. Top drive console is made according to the top drive produced by Beijing Petroleum Machinery Factory. Ti can simulate various operation, co-movement relation and control logic of top drive, including IBOP, turret lock, links rotation, links tilting, clamp, operation select (drill, spin, torque), direction select (CW, stop, CCW), etc

|

|

Top drive console Feature: simulating top drive produced by Beijing Petroleum Machinery Factory •Control top drive device |

-

Drawworks controlismade according to the model of onsite drawworks control.

|

|

Drawworks control handle Feature: operation methodisthe same as real control • Control top drive device raising and lowering |

2.2 System main software

-

Device principle multi-media software

-

Top drive device control software module

-

Sound effect control software module

-

System diagnostic module

-

Student management and automatic scoring software module

-

Top drive-based 3D scene display software module

2.3 System standard configuration

|

SN |

Name |

Technical specification |

Unit |

Q’ty |

|

1 |

Top drive console |

Simulating top drive produced by Beijing Petroleum Machinery Factory |

Set |

5 |

|

2 |

Drawwoks control handle |

|

Set |

5 |

|

3 |

Computer |

CPU: i7; memory: 16G; SSD240G; discrete graphic card |

Unit |

10 |

|

4 |

Monitor |

23 inch |

Unit |

10 |

|

5 |

Displaying system |

4K 80 inchLCDscreen |

Set |

1 |

|

6 |

Esimtech top drive simulator master control software |

Esimtech |

Set |

5 |

|

7 |

Esimtech top drive simulator graphic software |

Esimtech |

Set |

5 |

|

8 |

Student table and chair |

Special for education |

Set |

5 |

3. System function

3.1 Functions and features

-

The system provides conventional top drive operation, such as tripping in and out, drilling, IBOP, top drive making up, top drive breaking out, links rotation, etc. It can also provide training for common accidents, such as top drive reaming, back reaming, etc.

-

Top drive simulation system simulates the real equipment so that trainees can operate the system without any sequence restriction. The system can reflect any operations students made, just as operating a real top drive.

-

The system has the function of displaying top drive working principle by 3D animation. So that students can understand the working principle and maintenance of top drive better. The animation provides the display of working principle of IBOP, turret, links tilt and rotation structure.

-

The system can simulate accidents and faults. Instructor can insert various top drive faults at any time during exercise. Students can judge the faults through various phenomenon (such as different states of alarms).

-

The system adopts the working mode of step by step. Though it is a non-sequence system before each student, we provide the working mode of step by step. Under this mode, instructor can give lecture of top drive operation procedure step by step to enable students to master top drive operation quickly, such as working process of making up drill stand.

-

. The system can simulate various noises of well site. The noise is synchronic with students’ operation, working condition and graphic display.

-

The system has automatic scoring function.Itcan give scores to students’ operation, and gives point deduction reason, which makes training fair and just.

-

The system has complete students’ information management function.

3.2 Training items

3.2.1 3D animation display of top drive working principle

1) Turret lock

2) IBOP

3) Topdriverotation

4) Links tilting

3.2.2 Step-by-Step working mode

1) Trippingin

2) Tripping out

3) Topdrivemaking up

4) Topdrivebreaking out

5) Normal drilling

3.2.3 Non-sequence operation mode

1) Trippinginand out

2) Drilling

3.2.4 Problem treatment

1) Resistance during trip-out

2) Resistance during trip-in

4. Technical parametersandworkingenvironment

4.1 Technical parameters

-

Power: 220V/50Hz AC

-

Power consumption: <3000W

-

Resolution: 1920*1080

4.2 Working environment

-

Area: ≥10*8.5m

-

Working temperature: 0℃~30℃

-

Relative humidity: <90%

5. System whole layout and program interfaces

Figure 1 Top drive simulationlabeffect picture

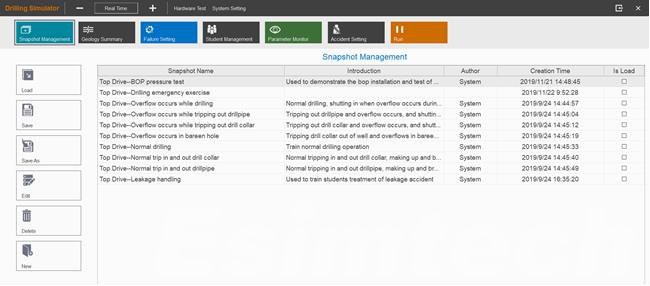

Figure2 Master control software interface

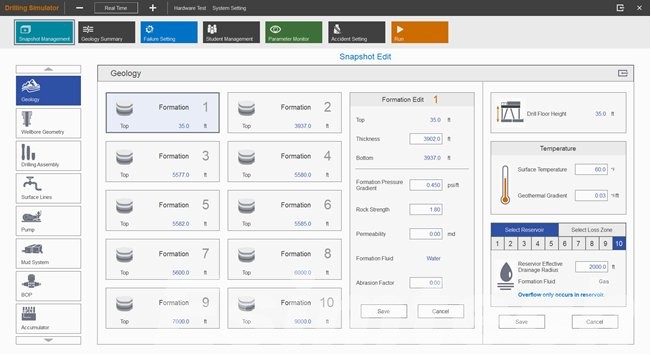

Figure 3 Software running interface

Figure 4 Graphic program running interface

Figure 5 Working principle display

F&Q

- What well control simulations does this well control simulator cover?

In well control operation, pressure control is very important. How the pressure is controlled? In the good control simulator, various scenes of kick can be simulated, both hard and soft shut-in procedure can be carried out. Meanwhile, various well-killing methods are provided, such as driller’s method, engineer’s method, volumetric method, bullhead, low choke method, standpipe pressure method, etc.

- What new petroleum simulations and features are you working on?

Esimtech has been committed in study and developing a petroleum engineering simulation training system for about 30 years, and has a series of independent intellectual property rights. Our simulators are widely used in many training companies with good feedbacks. To keep pace with the international standard and demand, Esimtech is now studying and developing an MPD simulator, where some achievement has been reached.

- Do you have any certifications?

Esimtech drilling and well control simulator has been approved by IWCF and IADC.

Since establishment, Esimtech has obtained a series of independent intellectual property rights, including invention patents in China and abroad.

Esimtech was granted as “High-tech Enterprise”, and has been awarded the third prize of “Science and Technology Progress”.

Esimtech has also obtained the certificates of ISO 9001, ISO14001 and ISO45001.

- Do you have simulators simulating offshore drilling platforms?

Esimtech provides drilling and well control simulator with offshore platform simulation.

- Is there a complete instruction for use if I ordered?

There will be completely operational instruction and maintenance instruction along with the package.