Preventing and Responding to Offshore Oil Spills

Offshore oil spills are some of the most devastating environmental disasters, threatening marine life, coastal ecosystems, and economies dependent on healthy oceans. As the demand for oil continues, offshore drilling has increased, heightening the risk of such accidents.

What are the Causes of Petroleum Spills

Petroleum spills can occur both on land and offshore, caused by a variety of human activities, equipment malfunctions, or natural events. Some of the most common causes include:

- Operational Accidents: Human error, equipment failure, and inadequate safety protocols during drilling, extraction, or transportation can lead to oil spills. This includes pipeline ruptures, blowouts, and leaking storage tanks.

- Transport Incidents: Oil is often transported via tankers, pipelines, and barges. Accidents, such as collisions, groundings, or pipeline ruptures, can result in significant spills.

- Natural Disasters: Hurricanes, earthquakes, and tsunamis can severely damage offshore oil platforms, leading to ruptures in pipelines or wells.

- Illegal Discharges: Deliberate illegal dumping or operational discharges from vessels contribute to oil spills, especially in coastal and international waters.

- Structural Corrosion and Aging Equipment: Offshore platforms and oil tankers are subject to wear and tear over time. If equipment is not properly maintained, structural failures can result in oil leaks.

Offshore Oil Spills

Offshore oil spills present unique challenges due to the complex nature of the marine environment and the vast areas involved. Large-scale offshore drilling operations, such as those in the Gulf of Mexico, have a significant environmental risk. The 2010 Deepwater Horizon oil spill is one of the most notable examples, where millions of barrels of oil were released into the ocean, causing catastrophic damage to marine ecosystems and coastal economies.

These spills spread rapidly, often forming slicks that cover vast stretches of ocean and wash ashore, affecting beaches, marshes, and wildlife habitats. Marine organisms, including fish, birds, and mammals, can be poisoned, suffocated, or smothered by the oil. Coastal communities, which depend on fishing, tourism, and clean water, suffer economically from the loss of natural resources.

What are the Prevention Measures for Offshore Oil Spills

Preventing offshore oil spills requires a multi-layered approach that combines advanced technology, strict regulatory frameworks, and proactive environmental management. Given the complexity and risks associated with offshore drilling, implementing robust preventive measures is critical to minimizing the likelihood of oil spills. Below are several key strategies employed to prevent spills:

Robust Engineering and Equipment Standards

One of the primary means of preventing offshore oil spills is ensuring that all equipment used in drilling operations is of the highest quality and regularly maintained. Offshore rigs, pipelines, and wells operate in harsh oceanic conditions, making them vulnerable to wear, corrosion, and sudden pressure changes. To mitigate these risks:

- Blowout Preventers (BOPs): A BOP is a critical piece of equipment designed to close off an oil well if unexpected pressure or a “blowout” occurs. Modern BOPs are equipped with multiple redundant safety systems that can seal a well in case of emergency, preventing uncontrolled oil discharge.

- High-Quality Materials: Offshore infrastructure, such as drilling rigs and pipelines, are built from corrosion-resistant materials to withstand the harsh marine environment, reducing the risk of structural failure.

- Regular Maintenance and Upgrades: Routine inspections, corrosion monitoring, and timely equipment upgrades ensure that all operational systems remain in optimal condition, preventing leaks or equipment malfunctions.

Strict Regulatory Oversight

Governments and international organizations play a crucial role in establishing and enforcing regulations to ensure safe offshore oil drilling practices. These regulations help prevent accidents by holding companies accountable and setting high standards for operation. Key regulatory measures include:

- Licensing and Permits: Companies must obtain licenses and permits before they can drill in offshore environments. These permits are often contingent on detailed environmental and risk assessments that outline the measures a company will take to prevent spills.

- Regular Inspections and Audits: Regulatory agencies conduct periodic inspections of offshore platforms, pipelines, and tankers to ensure compliance with safety standards. Non-compliance can result in hefty fines or the suspension of operations.

- Safety Management Systems: Offshore oil operators are required to implement safety management systems (SMS) that outline all the operational procedures, risk management protocols, and emergency response plans that must be followed to prevent spills.

Advanced Monitoring Systems and Early Detection Systems

Real-time monitoring is a critical component in preventing oil spills, as it enables operators to detect leaks or equipment malfunctions before they result in a major disaster. Several technologies are employed to ensure constant surveillance:

- Subsea Sensors and Pressure Gauges: These devices continuously monitor pressure levels within pipelines and oil wells. Any sudden pressure changes can signal a potential leak or equipment failure, allowing operators to take corrective action immediately.

- Drones and Remote Operated Vehicles (ROVs): Drones and ROVs equipped with cameras and sensors can inspect hard-to-reach areas of offshore platforms, pipelines, and undersea infrastructure. This allows for early identification of damage, corrosion, or wear that could lead to leaks.

- Satellite and Aerial Surveillance: Satellite imagery and aerial monitoring provide a bird’ s-eye view of large areas, allowing for the rapid detection of oil slicks or unusual activity on the water’s surface. This method is especially valuable for early detection in remote areas where direct human oversight is limited.

- Automatic Shutdown Systems: Many modern oil rigs and platforms are equipped with automatic shutdown systems that kick in when an anomaly is detected, such as a sudden pressure surge or equipment failure. These systems can shut down drilling operations and close off oil wells to prevent blowouts or leaks.

Crew Training and Safety Protocols

Human error remains a significant cause of offshore oil spills. Therefore, ensuring that personnel working on offshore platforms are properly trained is essential for preventing accidents. Comprehensive training programs focus on:

- Emergency Preparedness: Drilling crews and operators must be trained to react swiftly and appropriately in the event of an emergency, such as a well blowout or a pipeline rupture. Simulations and regular drills prepare the crew to handle critical situations, such as activating blowout preventers or deploying containment booms.

- Routine Safety Procedures: Routine safety measures, including daily inspections, equipment checks, and adherence to operational protocols, are vital in preventing minor issues from escalating into major incidents. Training ensures that personnel understand these procedures and recognize their importance.

- Crew Communication and Coordination: Effective communication among the crew, especially in high-pressure situations, is essential for preventing mistakes. Advanced communication systems ensure that teams can quickly share information about potential risks or equipment malfunctions, enabling faster intervention.

Environmental Impact Assessments (EIAs)

Before any offshore drilling operation begins, an Environmental Impact Assessment (EIA) is conducted to identify potential environmental risks and determine the best strategies to mitigate them. EIAs are a vital part of the regulatory process, ensuring that companies take a proactive approach to environmental protection. The main components of an EIA include:

- Risk Identification: An EIA identifies the potential environmental risks associated with drilling, such as the likelihood of oil spills, habitat disruption, and impacts on marine life. This helps companies develop tailored preventive measures to minimize these risks.

- Oil Spill Contingency Planning: The EIA process requires companies to develop a comprehensive oil spill contingency plan, detailing the procedures for responding to an oil spill, including containment and recovery strategies.

- Stakeholder Consultation: The EIA process often involves consulting with local communities, environmental organizations, and scientists to assess the broader social and ecological impacts of offshore drilling. This collaborative approach ensures that all potential risks are considered before drilling begins.

How to Immediate Response to Offshore Oil Spills

In the event of an offshore oil spill, a rapid and coordinated response is critical to minimizing the damage. The immediate response to an oil spill typically follows these steps:

- Assess the Situation: Rapidly determining the spill’s size, location, and movement is crucial. Satellite imagery, aerial surveys, and on-site inspections help gauge the extent of the spill and prioritize response actions.

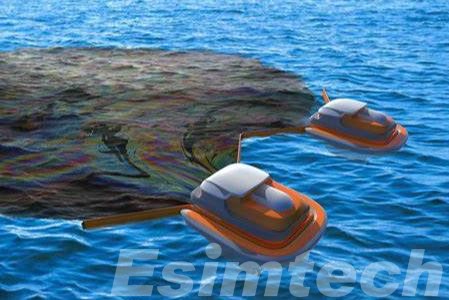

- Containment: Floating booms are deployed to encircle and contain the oil slick, preventing it from spreading to sensitive coastal areas. These barriers are essential to concentrate the oil for easier removal.

- Oil Recovery: Skimmers, vacuum trucks, and absorbent materials are used to recover as much of the oil as possible from the water’ s surface. In some cases, oil-eating bacteria or dispersants may be deployed to break down the oil into smaller particles that naturally degrade over time.

- Protecting Sensitive Areas: Efforts are made to prevent oil from reaching shorelines, estuaries, and wetlands. Booms, barriers, and protective berms can be used to safeguard these vulnerable ecosystems.

- Shoreline Cleanup: If oil reaches the shore, cleanup teams use a variety of techniques such as manual removal, washing, and bioremediation to clean the affected areas. This process is labor-intensive and can take months or even years, depending on the spill’s size.

- Wildlife Rescue: Specialized teams work to save and rehabilitate affected wildlife. Birds and marine mammals are particularly vulnerable, and rescuers clean oil from their bodies and provide medical care to those exposed.

Advancements in Oil Spill Prevention and Response

Over the years, significant advancements in technology and methodology have improved both prevention and response efforts. Key developments include:

- Automated Leak Detection Systems: Advanced monitoring systems, such as subsea sensors and drones, are capable of detecting leaks in pipelines and rigs before they become large-scale spills. These systems help companies to act early, avoiding disasters.

- Improved Blowout Preventers: Newer blowout preventers are designed with multiple fail-safes, making them more reliable in the event of an equipment failure. They also include better remote operation capabilities, allowing crews to quickly seal off wells in an emergency.

- Dispersant Technology: Modern chemical dispersants are designed to break oil down more efficiently, allowing natural microbial processes to degrade the oil faster. New eco-friendly dispersants have been developed that minimize harm to marine life while maximizing oil dispersion.

- Oil Skimmers and Recovery Techniques: Advances in skimming technology now allow for faster oil recovery from the water’s surface. These innovations include more efficient vacuum systems, centrifuge technology, and absorbent materials that maximize recovery in varying sea conditions.

Preventing and responding to offshore oil spills is a critical yet challenging endeavor vital for safeguarding marine ecosystems and coastal economies. As offshore drilling activities continue to rise, the associated risks also increase. However, advancements in technology, stricter regulations, and effective response strategies offer promising avenues for reducing the impact of such disasters. Ongoing enhancements in engineering, monitoring, and recovery techniques will play a key role in minimizing both the likelihood and consequences of future spills.