Petroleum Pipeline in Oil and Gas Transportation

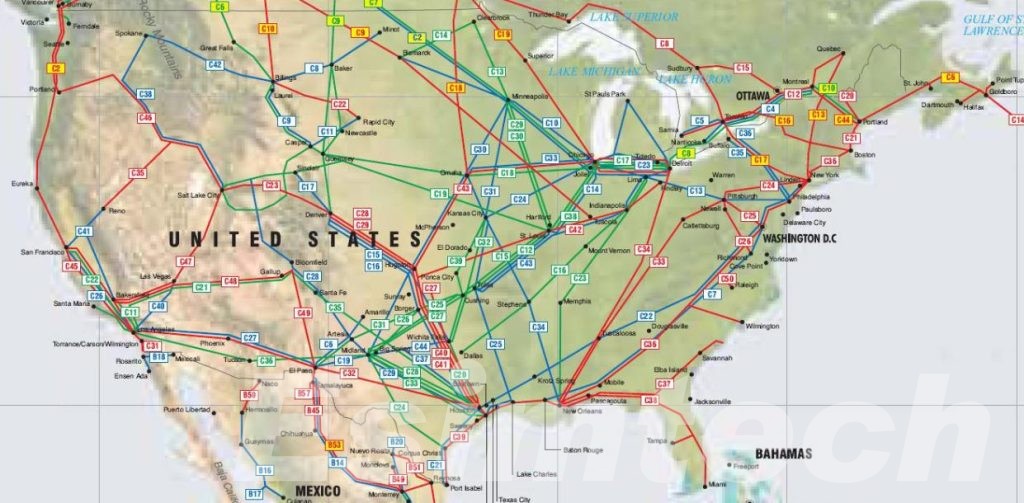

Petroleum pipelines are vital for the smooth and efficient transportation of crude oil, refined products, and natural gas over long distances. As one of the most cost-effective and safest methods of moving large volumes of these energy sources, pipelines form the backbone of the oil and gas transportation industry.

How Petroleum Pipelines Work

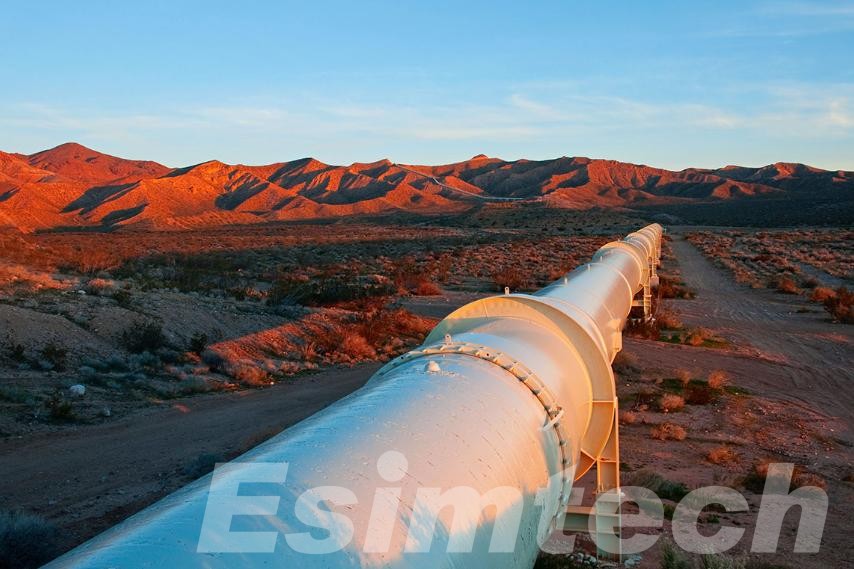

Petroleum pipelines are designed to transport oil, gas, and refined products over long distances through a system of pipes, pumps, and control mechanisms. The process begins at production sites like oil fields or refineries, where crude oil or gas is pumped into the pipeline. From there, it travels through a series of underground or above-ground pipes, reaching distribution hubs, storage tanks, or other refineries.

To maintain a smooth flow, pipelines are fitted with pumps that pressurize the fluid, driving it through the system. Some pipelines also utilize compressors to maintain pressure and ensure consistent flow. Along the pipeline, pump stations control pressure and monitor the system for any potential issues. Valves and other control mechanisms enable operators to regulate the flow and isolate sections of the pipeline when necessary. Modern pipelines are carefully monitored for leaks and other potential concerns to guarantee the safe, continuous transport of petroleum products.

Importance of Petroleum Pipelines in Oil and Gas Transportation

Petroleum pipelines are a vital element in the oil and gas transportation network, providing a range of benefits that support both economic and environmental goals. Here are several key points highlighting their importance:

- Safety: When properly built and maintained, pipelines are among the safest methods for transporting petroleum products. The risk of accidents or spills is lower compared to alternatives like road or rail, as pipelines are typically monitored and equipped with safety features designed to prevent major failures.

- Efficiency: Pipelines are an exceptionally efficient means of transporting large quantities of oil and gas over long distances. Unlike other transport methods, such as trucks or trains, pipelines run continuously with minimal disruptions, ensuring a consistent and reliable flow of resources.

- Cost-Effectiveness: Although the initial construction of pipelines can be costly, their long-term operational expenses are lower than other transportation methods. Once installed, pipelines demand less labor, energy, and maintenance, making them a more cost-effective solution for the ongoing transport of oil and gas.

- Energy Security: Pipelines ensure a stable and secure supply of oil and gas to refineries, power plants, and storage facilities. This uninterrupted flow is critical for energy security, supporting both local and global energy demands and enabling the steady operation of industries dependent on these resources.

- Environmental Impact: In comparison to road or rail transportation, pipelines have a smaller environmental footprint. They reduce the reliance on fuel-intensive vehicles and help lower emissions, fostering a more sustainable and environmentally friendly system for transporting petroleum products.

Innovations Technologies Used for Petroleum Pipeline Works

The petroleum pipeline industry is adopting advanced technologies to improve safety, efficiency, and monitoring. These innovations have led to enhanced operational capabilities, reducing risks and optimizing maintenance.

Pipeline Inspection

Pipeline inspection is essential for maintaining the safety and integrity of petroleum pipelines. Modern inspection technologies have made it possible to detect potential issues before they become serious problems.

- Smart Pigs: These are intelligent inspection tools that travel inside the pipeline, collecting data about the pipe’s condition. They can detect issues like corrosion, cracks, and other structural defects without interrupting pipeline operations.

- Aerial Drones: Drones are being increasingly used to inspect pipelines, particularly in remote or hard-to-reach areas. Equipped with cameras and sensors, they provide real-time visual feedback and other important data to operators, improving the efficiency of routine inspections.

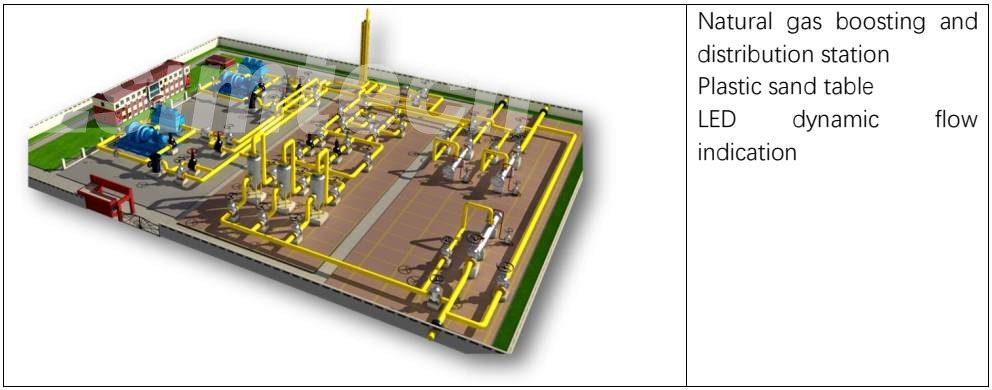

Remote Monitoring and Control

Advancements in remote monitoring and control technologies have made pipeline operations more efficient and responsive:

- Real-Time Data Collection: Sensors embedded along pipelines gather data on pressure, temperature, flow rate, and other critical parameters. This data is transmitted to control centers for continuous monitoring.

- Automated Control Systems: These systems enable operators to adjust the flow and pressure of the pipeline from remote locations. Automated systems can also make adjustments based on real-time data, ensuring optimal pipeline performance.

- Integrated Systems: Remote monitoring platforms integrate data from various sensors, providing operators with a comprehensive view of pipeline conditions. This centralized system allows for faster detection of irregularities and enables quicker responses to potential issues.

Simulation Training

Simulation training is an innovative technology that has significantly improved how operators are trained to handle pipeline operations. This technology provides a virtual environment for operators to practice and prepare for real-world scenarios without putting the actual infrastructure at risk.

- Virtual Environments: Using computer-generated simulations, operators can experience realistic pipeline scenarios, from routine operations to emergency situations like leaks or equipment failure.

- Scenario-Based Training: These simulations can replicate complex situations, such as changes in pressure, pipeline ruptures, or sudden drops in temperature, helping operators learn how to respond quickly and effectively to potential problems.

- Enhanced Decision-Making Skills: By practicing in a controlled virtual environment, operators develop critical decision-making skills, improve their ability to manage unexpected issues, and enhance their overall preparedness for pipeline management.

Leak Detection Systems

Detecting leaks early is crucial in preventing environmental disasters and ensuring the safe operation of pipelines. Advanced leak detection technologies are now available to help identify leaks as soon as they occur.

- Acoustic Sensors: These sensors listen to the sounds produced by gas or liquid leaks. By analyzing these acoustic signals, the system can pinpoint the location of a leak.

- Pressure Drop Monitoring: This method compares the pressure across different sections of the pipeline. If a drop in pressure is detected, it could indicate a potential leak, prompting an immediate investigation.

- AI-Powered Detection: Machine learning algorithms are now being used to enhance leak detection systems. By analyzing historical data and identifying patterns, AI can predict potential leak sites before they happen, enabling preventive measures.

These technologies are transforming the petroleum pipeline industry by enhancing the safety, efficiency, and reliability of pipeline operations, and they continue to evolve as new advancements emerge.

Key Takeaways

Petroleum pipelines are essential for efficient, safe, and cost-effective oil and gas transportation, ensuring energy security and reducing emissions. Innovative technologies like smart inspection tools, remote monitoring, leak detection, and simulation training are improving pipeline safety, efficiency, and environmental protection. As the industry evolves, these advancements will help maintain the crucial role of pipelines in global energy transportation, ensuring a safer and more sustainable future.