Optimizing Well Stimulation for Different Reservoir Types

Well stimulation is a key process in the oil and gas industry, which increases hydrocarbon production by improving reservoir permeability and oil well productivity. The effectiveness of production enhancement treatment largely depends on the specific characteristics of the reservoir. Today we will explore the diversity of oil reservoirs, their unique properties, and corresponding strategies for optimizing oil well production. In addition, we will delve into the latest technological advancements in this field.

Overview of Oil Reservoir Types

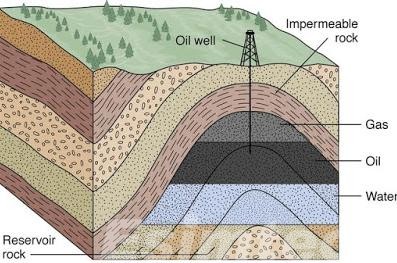

Oil reservoirs are the underground rock formations where crude oil and natural gas accumulate. These geological structures vary widely in terms of their composition, formation, and physical properties, significantly impacting the methods used to extract the hydrocarbons they contain.

Conventional Reservoirs

Conventional oil reservoirs are characterized by their relatively high porosity and permeability, allowing for the relatively easy flow of oil and gas. These reservoirs typically formed millions of years ago when organic matter buried beneath layers of sediment transformed into hydrocarbons.

- Sandstone Reservoirs: Composed of compacted sand grains, these reservoirs often exhibit good porosity, meaning they contain numerous interconnected pores. This allows for the storage and flow of hydrocarbons. However, the permeability, or the ability of fluids to move through the rock, can vary.

- Carbonate Reservoirs: Primarily made up of calcium carbonate or dolomite, these reservoirs can be highly complex. They often contain fractures and vugs (cavities) that enhance porosity and permeability. However, carbonate rocks can also be dense and impermeable, making production challenging.

Unconventional Reservoirs

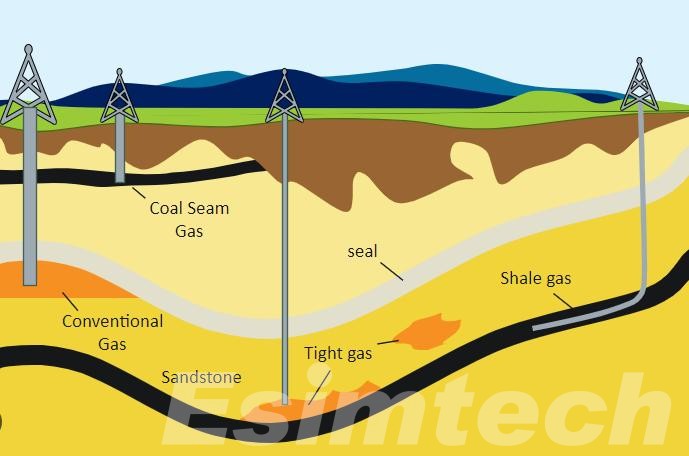

Unconventional reservoirs present a stark contrast to conventional ones. They are characterized by low porosity and permeability, making it difficult for hydrocarbons to flow freely. As a result, advanced technologies and techniques are required to extract these resources.

- Shale Formations: These fine-grained sedimentary rocks contain vast amounts of hydrocarbons trapped within tiny pores. Shale gas and shale oil have become significant energy sources due to advancements in hydraulic fracturing and horizontal drilling.

- Tight Sandstones: While similar to conventional sandstones, tight sandstones have significantly lower permeability, hindering hydrocarbon flow.

- Coal Bed Methane (CBM): Methane gas is adsorbed onto the surface of coal seams. Extracting this gas involves reducing the pressure within the coal formation to release the trapped methane.

Heavy Oil Reservoirs

Heavy oil, with a higher viscosity than conventional crude oil, poses unique challenges for production. These reservoirs require specialized methods to extract and process the thick, viscous oil.

- Oil Sands: Containing bitumen, a thick, semi-solid form of crude oil, oil sands require extensive processing to extract the usable hydrocarbons.

- Bakken Formation: While often classified as an unconventional reservoir due to its low permeability, the Bakken also produces heavy oil. A combination of horizontal drilling and hydraulic fracturing is used to extract the oil.

Characteristics of Oil Reservoir

The characteristics of an oil reservoir significantly influence its production potential and the methods employed to extract hydrocarbons. Key properties include:

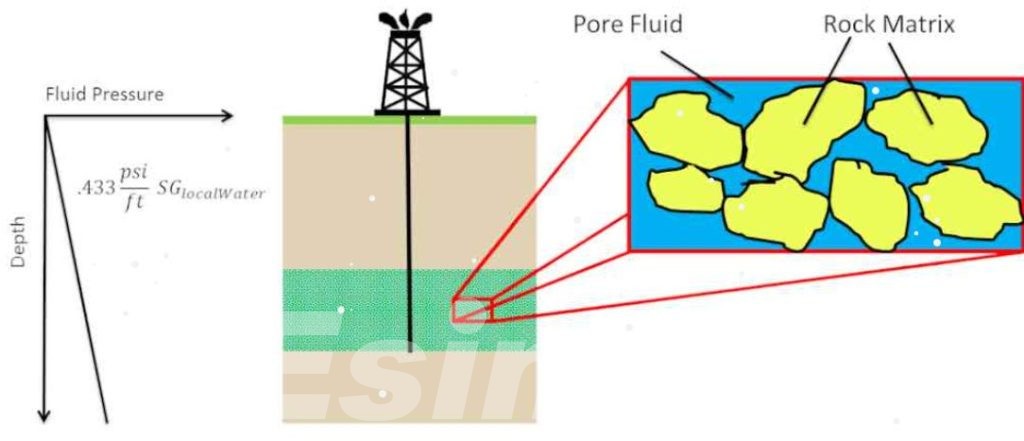

- Porosity and Permeability

Porosity: This refers to the void space within a rock, expressed as a percentage of the total rock volume. High porosity indicates a greater capacity to store hydrocarbons.

Permeability: This measures the ability of a rock to allow fluids (oil, gas, and water) to flow through its pore spaces. High permeability is essential for efficient production.

- Rock Type

The type of rock forming the reservoir plays a crucial role in its characteristics.

Sandstone: Often characterized by good porosity and permeability, making it a favorable reservoir rock. However, variations in grain size and cementation can affect these properties.

Carbonate Rocks: Limestone and dolomite exhibit diverse characteristics. They can range from highly porous and permeable to dense and fractured.

Shale: Typically has low porosity and permeability, necessitating unconventional extraction methods.

- Reservoir Pressure

The pressure within a reservoir drives the flow of hydrocarbons to the wellbore. Higher pressure generally results in higher production rates.

- Fluid Properties

The composition and properties of the fluids within the reservoir (oil, gas, and water) influence production behavior.

Oil Gravity: The density of the oil affects its flow characteristics. Heavier oils have higher viscosity and require specialized production techniques.

Gas-Oil Ratio (GOR): The ratio of gas to oil volumes affects production rates and facility design.

Water Saturation: The amount of water in the reservoir can impact oil recovery and production operations

- Reservoir Geometry

The shape and size of a reservoir influence its production performance. Factors such as thickness, areal extent, and structural complexity impact hydrocarbon recovery.

- Reservoir Heterogeneity

Variations in reservoir properties within a given formation can significantly affect production. These heterogeneities can include changes in porosity, permeability, and fluid saturation

Optimization Strategies for Different Reservoir Types

Optimizing well stimulation for various reservoir types involves tailoring techniques and approaches to the unique geological and fluid characteristics of each reservoir. Here, we delve deeper into the specific strategies used for different reservoir types:

Conventional Reservoirs

Hydraulic Fracturing: In conventional reservoirs with high permeability, hydraulic fracturing involves creating fractures in the rock to enhance the pathways for oil to flow to the wellbore. The process includes injecting a fluid mixture at high pressure to crack the rock and insert proppants, which keep the fractures open.

Acidizing: Acidizing is particularly effective in carbonate reservoirs where the rock can be dissolved by acid. Matrix acidizing targets the pore spaces, improving permeability by dissolving minerals. Acid fracturing creates fractures while simultaneously increasing permeability by etching the fracture faces.

Unconventional Reservoirs

Multi-Stage Hydraulic Fracturing: In shale and tight oil reservoirs, where permeability is extremely low, multi-stage hydraulic fracturing is essential. This technique involves fracturing the reservoir in multiple stages along the horizontal wellbore, creating an extensive network of fractures to increase contact with the reservoir and improve hydrocarbon flow.

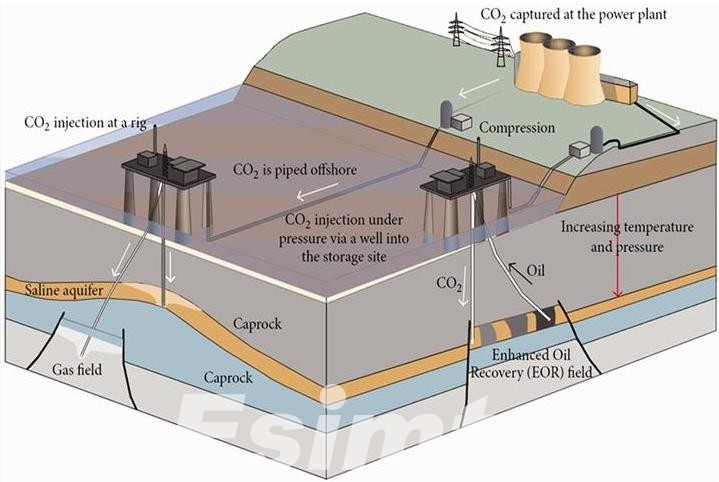

Enhanced Oil Recovery (EOR): EOR techniques are critical for unconventional reservoirs with high oil viscosity or low natural drive. Methods such as gas injection (CO2, nitrogen), thermal recovery (steam flooding), and chemical EOR (polymers, surfactants) help to improve oil mobility and increase recovery rates. For instance, CO2 injection can lower oil viscosity and swell the oil, pushing it towards the production well.

Carbonate Reservoirs

Matrix Acidizing: Matrix acidizing in carbonate reservoirs focuses on improving the near-wellbore permeability by dissolving carbonate minerals. The use of acids like hydrochloric acid (HCl) helps to create larger pore spaces and enhance fluid flow. This technique is particularly effective in heterogeneous carbonate formations with varying porosity and permeability.

Fracture Acidizing: For carbonate reservoirs with natural fractures, fracture acidizing is used to enhance the existing fractures. This technique involves injecting acid under pressure to open and etch the fractures, creating highly conductive channels that facilitate fluid flow from the reservoir to the wellbore.

Fractured Reservoirs

Re-fracturing: In naturally fractured reservoirs, re-fracturing can be employed to rejuvenate old wells or stimulate underperforming zones. This process involves re-opening and extending existing fractures to increase connectivity and improve production rates.

Waterflooding: Waterflooding is a secondary recovery method where water is injected into the reservoir to displace oil and push it towards the production well. This technique is particularly useful in fractured reservoirs where the natural fractures can serve as pathways for the injected water, enhancing oil displacement and recovery.

Technological Advances in Well Stimulation

The oil and gas industry has witnessed remarkable advancements in well stimulation technologies, enabling more efficient and effective hydrocarbon recovery. These innovations have significantly improved our ability to extract resources from increasingly complex and challenging reservoirs.

Downhole Tools and Sensors

Real-time monitoring and control of well stimulation processes have become essential for optimizing treatment design and execution. Downhole tools and sensors provide valuable data on pressure, temperature, and fluid flow rates, allowing engineers to make informed decisions during operations.

- Pressure and Temperature Sensors: Accurately measure downhole conditions to assess fracture growth and proppant placement.

- Flow Meters: Monitor fluid injection rates and identify potential issues such as fluid leaks or equipment malfunctions.

- Acoustic Sensors: Detect fracture initiation and propagation, providing insights into stimulation effectiveness.

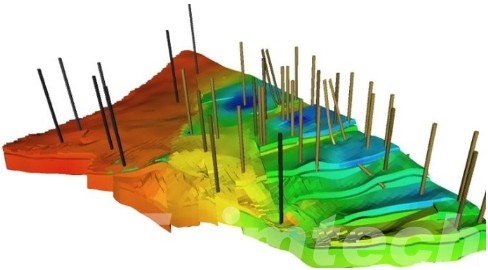

Modeling and Simulation

Advanced modeling and simulation software have revolutionized well stimulation design and optimization. These tools enable engineers to create detailed reservoir models, predict fracture growth, and evaluate different stimulation scenarios before field execution.

- Reservoir Simulation: Accurately represents reservoir geology, fluid properties, and production behavior to optimize well placement and stimulation designs.

- Fracture Modeling: Simulates the creation and propagation of fractures during hydraulic fracturing, helping to predict proppant distribution and well performance.

- Fluid Flow Simulation: Models fluid flow through the reservoir and wellbore to assess stimulation effectiveness and optimize production.

Fluid and Proppant Technologies

The development of innovative fluids and proppants has significantly enhanced stimulation performance. These materials are designed to optimize fracture creation, proppant placement, and long-term conductivity.

- Slickwater Fracturing: Using water-based fluids with minimal additives, this technique reduces costs and environmental impact while achieving effective fracture stimulation.

- Crosslinked Fluids: These fluids form a gel-like structure, improving proppant suspension and placement.

- High-Strength Proppants: Resistive to crushing under high reservoir pressures, these proppants maintain fracture conductivity.

- Conductive Proppants: Coated with materials that improve conductivity, these proppants enhance hydrocarbon flow.

Data Analytics and Machine Learning

The vast amounts of data generated during well stimulation operations provide valuable insights for optimizing future treatments. Data analytics and machine learning techniques are being applied to identify patterns, correlations, and trends.

- Predictive Modeling: Develops models to predict stimulation outcomes based on historical data and reservoir characteristics.

- Treatment Optimization: Identifies optimal stimulation parameters for specific reservoir conditions.

- Failure Analysis: Analyzes unsuccessful treatments to identify root causes and prevent future issues.

By harnessing these technological advancements, the oil and gas industry is continuously improving well stimulation practices, increasing hydrocarbon recovery, and reducing environmental impact.