Oil and Gas Gathering Systems: Offshore Fixed Platforms and Floating Platforms

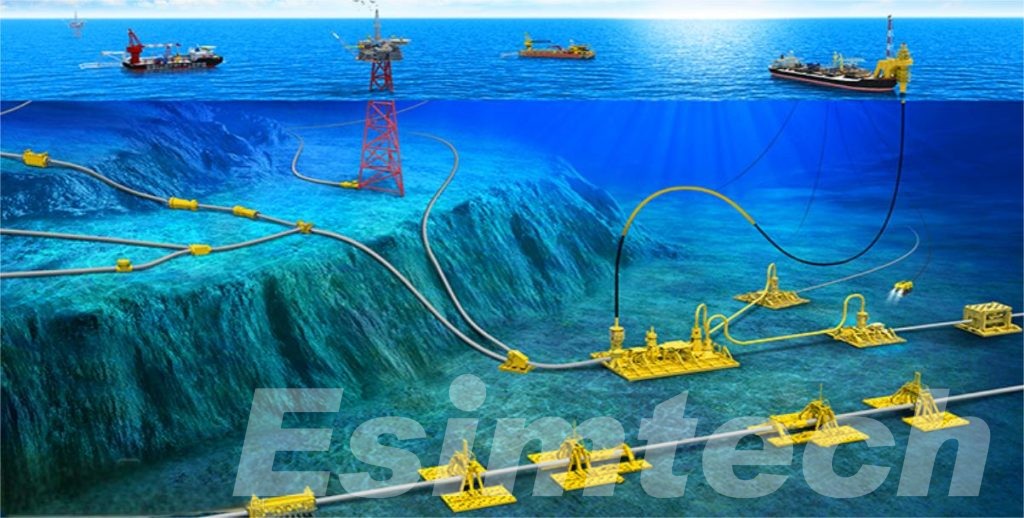

Offshore oil and gas gathering systems are integral to the extraction and transportation of hydrocarbons from subsea reservoirs to processing facilities. These systems include a network of pipelines, risers, and processing units that collect oil and gas from wells, ensuring that they reach the surface for further refinement and distribution. Offshore platforms, that support these systems, are categorized primarily into two types: fixed platforms and floating platforms. Each has its unique design, capabilities, and application scenarios.

What is Offshore Oil and Gas Gathering System?

The offshore oil and gas gathering and transportation system refers to the entire production process of collecting, measuring, processing, and pre-processing the crude oil and natural gas extracted from the oil wells in the offshore oil field, and finally delivering qualified oil and gas to users, as well as the general term for the engineering facilities and production equipment required to complete the above-mentioned gathering and transportation tasks.

The offshore oil and gas gathering and transportation system includes the offshore oil and gas production equipment system and the engineering facilities that provide production sites and supporting structures for it, such as wellhead platforms, production platforms, living platforms, oil storage platforms, oil storage tankers, oil storage tanks, single-point moorings, oil transfer terminals, etc. These facilities constitute a complex energy transportation network, involving multiple subsystems such as submarine pipelines, offshore platforms, and land pipelines, which require precise design and coordination.

Types of Offshore Oil and Gas Gathering System

Offshore oil and gas gathering systems are broadly classified into two main types based on the platform structure: fixed platforms and floating platforms. The choice between these platforms depends on various factors, including water depth, environmental conditions, and the size of the reservoir.

Offshore Fixed Platforms

Offshore fixed platforms are stationary structures anchored to the seabed. They are designed for shallow to moderate water depths, typically up to 1,500 feet. These platforms are built to withstand harsh environmental conditions, including strong waves, winds, and currents. The substructures of fixed platforms can be made of steel or concrete and are designed to offer stability and support to the topside facilities, which house drilling rigs, production equipment, and living quarters.

There are several types of fixed platforms, including:

- Steel Jacket Platforms: These are the most common type of fixed platform, consisting of a tubular steel frame (jacket) that is anchored to the seabed with piles. The topside facilities are mounted on the jacket.

- Gravity-Based Structures (GBS): These platforms rest on the seabed and rely on their weight to remain stable. GBS platforms are typically made of concrete and are used in shallow to moderate water depths.

- Compliant Towers: These are tall, slender structures that can sway with the waves, making them suitable for deeper waters (up to 3,000 feet) compared to traditional fixed platforms.

Offshore Floating Platforms

Offshore floating platforms are designed for deepwater and ultra-deepwater environments, typically exceeding 1,500 feet in depth. Unlike fixed platforms, floating platforms are not anchored directly to the seabed but are moored in place with anchors or dynamic positioning systems. These platforms are buoyant and can move with the ocean’s waves, currents, and wind, making them suitable for challenging offshore environments.

Key types of floating platforms include:

- Floating Production, Storage, and Offloading (FPSO) Units: FPSOs are ship-shaped vessels that process, store, and offload hydrocarbons. They are highly versatile and can be deployed in deep and ultra-deepwater fields.

- Tension Leg Platforms (TLPs): TLPs are buoyant structures anchored to the seabed with vertical tensioned tendons. They are designed to minimize vertical motion, making them stable for drilling and production in deep waters.

- Spar Platforms: Spar platforms consist of a long, cylindrical structure that extends deep into the water for stability. They are moored to the seabed and are used in very deep waters, often over 2,000 feet.

- Semi-Submersible Platforms: These platforms are partially submerged and rely on ballast to maintain stability. They are suitable for deepwater drilling and production and can be towed to different locations.

Offshore Fixed Platforms vs. Floating Platforms

The selection between fixed and floating platforms for offshore oil and gas operations is a complex decision that hinges on numerous factors. Each type offers distinct advantages and disadvantages, influencing the overall project’s feasibility, cost-effectiveness, and environmental impact.

| Feature | Fixed Platforms | Floating Platforms |

| Water Depth | Shallow waters | Deep waters |

| Seabed Conditions | Requires a stable seabed for anchoring | Can be used in challenging seabed conditions, such as soft sediments or steep slopes |

| Production Capacity | May have limitations due to the size and weight of the platform | Can handle larger production volumes, making them suitable for large-scale offshore fields |

| Environmental Factors | More sensitive to environmental conditions, such as hurricanes and earthquakes | More adaptable to environmental changes, making them suitable for regions with frequent storms or seismic activity |

| Construction and Maintenance | Generally more cost-effective to construct and maintain, especially in shallow waters | Typically more expensive to construct and operate, due to their complex engineering and specialized equipment |

| Stability | Highly stable due to their direct connection to the seabed | Can be less stable in certain conditions, such as during severe storms or high waves |

| Flexibility | Less flexible due to their fixed position | More flexible, allowing them to be moved to different locations or adapted to changing production requirements |

| Adaptability | Less adaptable to changing conditions | More adaptable to changing conditions, making them suitable for areas with fluctuating production rates or evolving field development plans |

The choice between fixed and floating platforms for offshore oil and gas depends on water depth, seabed conditions, production needs, and environmental factors. Fixed platforms are stable and cost-effective in shallow waters while floating platforms are flexible and adaptable in deepwater environments. By carefully evaluating these factors, operators can select the most suitable platform type for efficient, safe, and sustainable offshore operations.

Offshore oil and gas gathering systems play a vital role in the development and exploitation of offshore oil and gas fields. The choice between fixed and floating platforms depends on a variety of factors, including water depth, seabed conditions, and project requirements. By carefully considering these factors, operators can select the most suitable platform type to meet the needs of their offshore operations.