Oil And Gas Equipment: What are Key Categories and Why Simulation Is Important for Them

A complex and interconnected network of equipment designed to extract, process, and transport hydrocarbons efficiently and safely is at the heart of the oil and gas industry. This article delves into the world of oil and gas equipment, emphasizing its critical role in meeting our energy needs as well as simulation applications in oil and gas equipment.

Key Categories of Oil and Gas Equipment

Exploration and Drilling Equipment

Exploration is the first step in harnessing oil and gas resources. Seismic sensors, geophysical instruments, and advanced imaging technologies are used to locate potential reserves. Drilling equipment is used once a potential site has been identified. Modern onshore and offshore drilling rigs are engineering marvels capable of reaching deep into the Earth’s crust to tap into reservoirs. The equipment used in drilling operations includes drill bits, drill collars, and drilling mud pumps, all designed to withstand extreme pressures and temperatures.

Production and Extraction

The production phase begins after successful drilling. The extraction of crude oil or natural gas from underground reservoirs is part of this phase. Pumps, separators, and wellheads are among the equipment used. These elements collaborate to bring hydrocarbons to the surface while separating any associated water, gas, or solids. It is critical to extract and handle these resources safely in order to minimize environmental impact and ensure worker safety.

Processing and Refining

Impurities and a variety of hydrocarbon compounds are common in raw crude oil and natural gas. Processing and refining are important steps in converting raw materials into usable products. The equipment used in refining crude oil into valuable products such as gasoline, diesel, jet fuel, and petrochemicals includes distillation towers, fractionators, and catalytic converters.

Transportation

Once these products have been processed, the next challenge is to transport them efficiently and safely. Pipelines, tankers, and railcars are important parts of the transportation network. Pipelines are the preferred mode of transport for moving oil and gas over long distances, whereas tankers and railcars are used to transport products to various destinations. To avoid accidents and oil spills, these pieces of equipment must meet stringent safety and environmental standards.

Storage and Distribution

Storage tanks are crucial in maintaining a steady supply of oil and gas products. These tanks, often found at refineries, distribution centers, and ports, help regulate the flow of products to meet market demands. Moreover, distribution equipment like loading racks, pumps, and metering systems play a role in loading tank trucks and other delivery vehicles for the final leg of the journey to consumers.

Safety and Environmental Protection

In the oil and gas industry, safety and environmental protection are of the utmost importance. Blowout preventers, flame arrestors, and safety valves are used to prevent accidents and reduce the severity of equipment failures. Extensive monitoring systems are also in place to detect leaks, emissions, and other potential problems, ensuring that the industry operates responsibly.

The Vital Role of Simulation in Oil and Gas Equipment

The oil and gas industry is known for its complex and high-risk operations, from exploring and drilling in remote offshore locations to refining and transporting volatile hydrocarbons. In such a challenging environment, the use of simulation technology has become indispensable.

Applications of Simulation in Oil and Gas Equipment

Exploration and Drilling

Identifying potential reserves and drilling wells are the first steps in the oil and gas industry. Seismic imaging and reservoir modeling use drilling and well control simulation systems to allow geologists and engineers to estimate the size and characteristics of underground reservoirs. This aids in effectively planning drilling operations, reducing the likelihood of dry wells, and optimizing resource recovery.

Drilling Operations

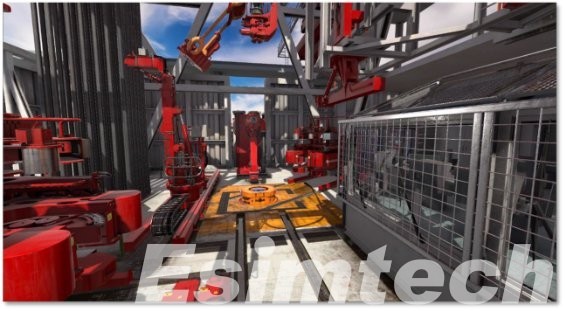

Drilling in the oil and gas industry is a complex task that is frequently performed in hazardous environments such as deep sea locations or areas with extreme temperatures and pressures. Drilling engineers can use simulation software to design and plan drilling operations, predict potential issues such as blowouts, and test different drilling strategies virtually before executing them in the field.

Reservoir Management

Reservoir simulation is an important part of optimizing hydrocarbon recovery. Simulators generate 3D models of reservoirs that include geological and fluid data. Engineers can then run simulations of various production scenarios, adjusting parameters such as well placement, injection rates, and pressure management to maximize recovery and minimize resource waste.

Equipment Design and Testing

The development of oil and gas equipment, from drilling rigs to refining units, benefits greatly from simulation. Engineers can create detailed virtual prototypes of equipment, running simulations to assess performance, structural integrity, and efficiency. This saves time and resources by identifying and addressing design flaws early in the development process.

Training and Skill Development

The operation of oil and gas equipment demands a high level of expertise. Simulation-based training allows workers to practice their skills and familiarize themselves with equipment in a safe, controlled environment. Drilling simulation training system not only enhances safety but also improves efficiency by reducing errors and downtime.

Safety and Emergency Preparedness

Simulating emergencies, such as well blowouts or equipment failures, is an essential component of industry safety protocols. Teams can better prepare for real-world crises by practicing emergency response procedures in a simulated environment, helping to mitigate the impact of accidents and reduce the risk to personnel and the environment.

Advantages of Simulation in the Oil and Gas Industry

Risk Reduction

Simulation helps to prevent accidents, reduce downtime, and minimize environmental damage by identifying potential issues and assessing risks before they occur.

Cost Savings

Virtual testing and prototyping eliminate the need for costly physical prototypes and reduce operational expenses by optimizing equipment performance and operational strategies.

Efficiency Improvement

Simulation allows for the fine-tuning of equipment and processes, leading to more efficient resource extraction and processing.

Environmental Responsibility

Simulations can be used to model and minimize environmental impact, aiding in compliance with regulations and sustainable practices.

Knowledge Transfer

Simulation-based training and knowledge-sharing platforms ensure that skills and expertise are passed down from experienced workers to new generations.

Operational Flexibility

Drilling simulators allow operators to quickly adapt to changing conditions and challenges, ensuring that operations run smoothly even in dynamic environments.

Conclusion

Oil and gas equipment is critical to meeting our energy demands, powering economies, and fueling our daily lives. This industry relies on a wide range of specialized tools and machinery for everything from exploration to production, processing, transportation, storage, and distribution. Simulation is a powerful tool in oil and gas equipment, with numerous applications that improve efficiency, safety, and environmental stewardship. As the industry faces new challenges, simulation in the oil and gas industry becomes increasingly important in meeting the demand for responsible and sustainable energy solutions.