Offshore Drilling for Oil: How Does It Work Exactly

A Brief History of Offshore Drilling

Offshore drilling, the process of extracting oil and natural gas from beneath the seabed, has been a vital part of the global energy landscape for over a century. Its history is marked by technological advancements, environmental challenges, and significant contributions to the world’s energy supply.

Early Beginnings and Technological Advancements

The earliest recorded attempts at offshore drilling date back to the late 1890s, with wooden platforms constructed on shallow waters near California’s coastline. Technological advancements in the 1930s and 1950s, such as the development of steel platforms, mobile offshore drilling units (MODUs), and directional drilling, enabled drilling in deeper waters and more remote locations, expanding the potential for offshore exploration and production.

Environmental Concerns and Technological Innovations

As offshore drilling activities expanded, so did concerns about their environmental impact. The 1969 Santa Barbara oil spill highlighted the potential risks of offshore drilling, leading to stricter environmental regulations in the 1970s and 1980s. Technological innovations in the 1990s, such as improved seismic imaging and ultra-deepwater drilling equipment, enabled exploration and production in deepwater reserves, located in waters deeper than 1,000 meters (3,281 feet).

Offshore Drilling Today and the Future

Today, offshore drilling remains a critical component of the global energy supply. The Deepwater Horizon oil spill in 2010 brought renewed focus on safety and environmental protection measures, leading to stricter regulations and industry-wide reforms. The future of offshore drilling is likely to involve further exploration of deepwater and ultra-deepwater reserves, the development of cleaner drilling technologies, and a focus on sustainable energy production. As the world seeks to transition to a low-carbon future, offshore drilling will play a role in meeting energy needs while minimizing environmental impacts.

Offshore Drilling: Finding, Extracting & Transporting Crude Oil

Finding oil is the initial step in the offshore drilling process. This is achieved by emitting high-pressure sound waves from a specialized device that utilizes compressed air. These sound waves travel to the ocean floor, bounce back, and are captured by underwater microphones called hydrophones. Scientists analyze this information to identify regions with potential oil and gas reserves.

Exploratory Wells

Once a potential oil reserve has been found, an exploratory well will be drilled. This is done with a Mobile Offshore Drilling Unit, or MODU.

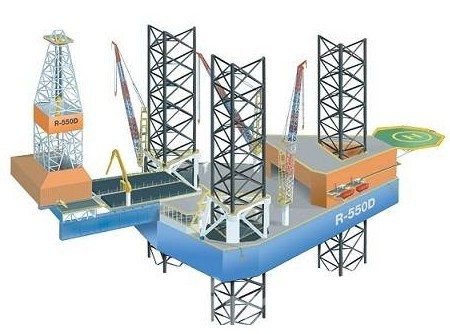

There are five main types of MODUs:

1. Jackup rigs: Jackup rigs are the most common type of MODU. They have long legs that can be lowered to the seafloor and raised up to allow the rig to be moved to a new location. Jackup rigs typically operate in water depths of up to 300 feet.

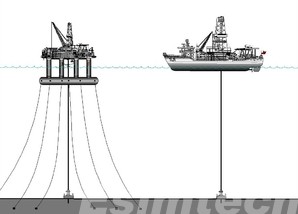

2. Semisubmersible rigs: Semisubmersible rigs are another common type of MODU. They have large pontoons that provide buoyancy and stability and a submerged hull that contains the drilling equipment. Semisubmersible rigs typically operate in water depths of up to 3,000 feet.

3. Drillships: Drillships are large, ocean-going vessels that can drill in water depths of up to 12,000 feet. They are more expensive to operate than jackup or semisubmersible rigs, but they are able to drill in deeper waters and are more versatile for exploration purposes.

4. Tensegrity rigs: Tensegrity rigs are a newer type of MODU that are designed to be more stable and efficient than traditional rigs. They have a unique structural design that uses tensioned cables and struts to support the drilling platform. Tensegrity rigs are still in the development stage, but they have the potential to revolutionize offshore drilling.

5. Submersible rigs: Submersible rigs are the least common type of MODU. They are completely submerged in water and are connected to the surface by a riser pipe. Submersible rigs are only used in very deep water, typically over 10,000 feet.

Depending on the type of well and its location, as well as the type of MODU used, an initial well will be drilled and the MODU may be replaced with a more permanent rig to handle ongoing oil production.

Oil Production

The type of oil production platform used to drill commercially viable oil wells depends on various factors, such as water depth, well depth, distance from shore, and the type of offshore environment. In some cases, the same mobile offshore drilling unit (MODU) can be used for both exploration and production.

Here are the main types of production platforms and their typical operating depths:

- Fixed platforms: up to 1,500 feet

- Compliant towers: 1,000 to 2,000 feet

- Tension leg platforms: up to 4,000 feet

- Mini-tension leg platforms: smaller deep-water oil reserves

- SPAR platforms: up to 3,000 feet

- Floating production systems (FPSOs): ultra-deepwater drilling and oil storage

- Subsea systems: deeper than 5,000 feet

These offshore oil production platforms extract and process crude oil from the rock formations below the seabed. They house the equipment and crew necessary to maintain offshore oilfields, process extracted oil, and transport it to the coast. Offshore platforms are large and complex, often requiring a crew of over 100 workers. Due to their remote locations, crews must live and work on the platform for extended periods.

Transportation

Most offshore production platforms are not meant to store oil onboard; extensive pipeline systems are used to transport oil from platforms to the coast for processing and distribution. Infield pipelines, often referred to as feeder lines or flowlines, are used to transport a mixture of oil, gas, and water from subsea wells to platforms. Export pipelines move processed oil or gas from a platform to the coast.

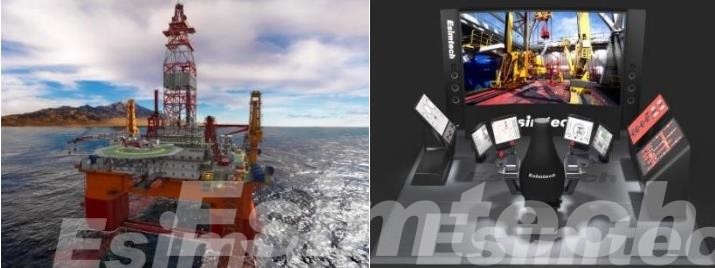

The Role of Simulation Technology in the Working of Offshore Drilling

Offshore oil exploration and production are complicated and often dangerous undertakings. So simulation Technology may be a good choice for oil and gas companies. Hrer are reasons:

- Improved safety: Simulation training reduces accident risks by providing a safe environment for practicing drilling operations.

- Increased efficiency: Simulation models optimize drilling parameters and identify potential problems early, saving time and money.

- Reduced costs: Simulation technology improves safety, efficiency, and reliability, reducing overall offshore drilling costs.

Examples of Simulation Technology Use

- Training: Simulation training is used to train offshore drilling personnel on well control, crane operation, firefighting, Production and Transportation process.

- Planning and Optimization: Simulation models plan and optimize drilling operations in wellbore trajectory, drilling fluid selection, casing design, and other areas.

- Troubleshooting: Simulation models troubleshoot problems like stuck pipe and lost circulation during drilling operations.

Esimtech has a serial of proprietary products in simulation system of petroleum engineering and petroleum equipment. Esimtech, adhering to the concept of “Producing the best simulator; make training more efficient”, provides products with excellent quality, and creates values for customers.

If you have any questions, please feel free to get in touch with our knowledgeable service team. We will be happy to assist you as soon as possible.