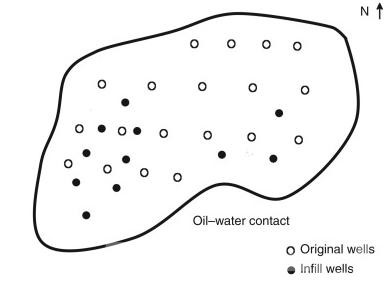

Maximizing Reservoir Potential through Strategic Infill Drilling

Efficient reservoir exploitation is critical to the energy sector, driving the need for innovative methods to maximize hydrocarbon recovery. Among these methods, strategic infill drilling has emerged as a powerful technique to enhance reservoir potential. This article delves into the challenges of reservoir exploitation, the benefits of strategic infill drilling, key considerations for its implementation, and the advanced techniques that can optimize this process.

Challenges of Reservoir Exploitation

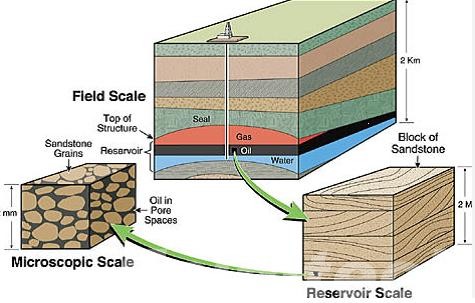

Reservoirs, analogous to subterranean treasure troves, hold vast quantities of valuable hydrocarbons. However, unlike readily accessible surface resources, extracting these riches presents a unique set of challenges that strategic infill drilling seeks to address.

- Declining Reservoir Pressure: The initial production phase of a reservoir is characterized by high pressure, facilitating the natural flow of oil and gas towards production wells. However, as extraction progresses, a phenomenon known as reservoir pressure decline inevitably occurs. This reduction in pressure significantly hinders the mobility of remaining hydrocarbons, making it increasingly difficult to efficiently extract them using existing wellbores.

- Geological Heterogeneity: Reservoirs are not uniform geological formations. Permeability, a measure of a rock’s ability to transmit fluids, can vary significantly within a single reservoir. These heterogeneities can lead to uneven drainage, where existing wells extract resources disproportionately from areas with high permeability, leaving behind pockets of hydrocarbons trapped in less permeable zones.

- Technological Limitations: Early exploration and drilling technologies may not have been sophisticated enough to fully characterize a reservoir’s intricacies. This can result in suboptimal well placement, where initial wellbores fail to capture the full potential of the reservoir. These limitations leave behind significant reserves that remain inaccessible with the existing well configuration.

The combined effect of these challenges creates a scenario where a seemingly abundant resource becomes increasingly difficult and expensive to extract. Strategic infill drilling offers a solution, acting as a targeted intervention to unlock the remaining potential within the reservoir and maximize the ultimate recovery rate.

Benefits of Strategic Infill Drilling

As a mature reservoir enters the decline phase of its production cycle, the challenges of extraction become more pronounced. Strategic infill drilling offers a compelling solution, acting as a rejuvenating force that unlocks significant benefits for operators.

- Increased Hydrocarbon Recovery: The primary and most direct benefit is the ability to access previously untapped reserves. By strategically placing wells in areas with high hydrocarbon saturation, infill drilling bypasses limitations imposed by existing well placement and reservoir pressure decline. This translates to a significant boost in total production output, extending the period of peak profitability for the project.

- Enhanced Reservoir Management: Infill drilling provides valuable new data points within the reservoir. This additional information, obtained through downhole sensors placed in the new wells, improves the overall understanding of the reservoir’s characteristics. With a more comprehensive picture of pressure distribution, fluid flow patterns, and remaining hydrocarbon saturation, operators can implement more effective reservoir management strategies. These include:

- Pressure Maintenance Techniques: By injecting water or gas into specific areas of the reservoir, infill drilling allows for more targeted pressure support, ensuring optimal flow towards production wells.

- Improved Sweep Efficiency: Understanding the flow dynamics within the reservoir through infill well data allows for adjustments in production and injection strategies, leading to a more even sweep of the reservoir and maximizing the amount of recoverable oil and gas.

- Extended Field Life: Traditionally, as production declines and extraction becomes uneconomical, operators are forced to explore for new reserves. Strategic infill drilling offers a cost-effective alternative by extending the productive life of an existing field. By accessing previously untapped resources and optimizing recovery rates, infill drilling allows operators to continue generating revenue from a mature asset for a significantly longer period. This not only delays the need for significant investments in new exploration ventures but also provides additional time to plan for a smooth transition when the field eventually reaches its end of life.

- Improved Profitability: The combined benefits of increased production, enhanced reservoir management, and extended field life translate to a significant boost in overall project profitability. Infill drilling can breathe new life into a maturing asset, generating additional revenue streams and maximizing the return on investment for the operator.

Key Considerations for Strategic Infill Drilling

Strategic infill drilling is not simply a matter of drilling additional wells within a reservoir. To maximize its effectiveness and ensure a positive return on investment, careful planning and meticulous execution are paramount. Here are the key considerations that differentiate a successful infill drilling campaign from a haphazard one:

- Reservoir Characterization: In-depth understanding of the reservoir’s geological makeup is crucial for identifying optimal locations for new wells. This involves utilizing advanced techniques like:

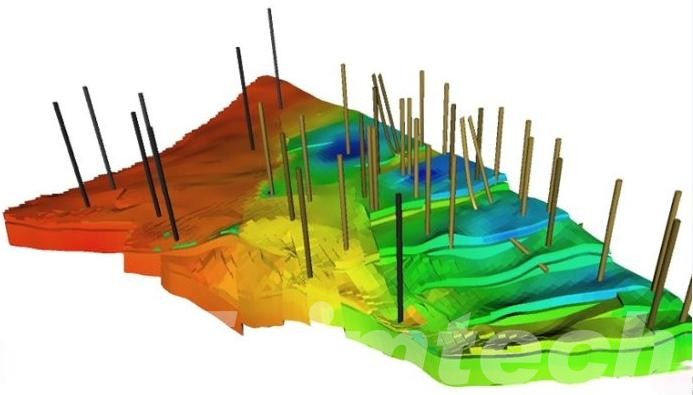

- 3D Seismic Imaging: High-resolution seismic surveys create detailed three-dimensional images of the reservoir, revealing variations in rock formations, porosity, and permeability.

- Reservoir Modeling: Advanced software utilizes seismic data, wellbore logs, and production history to create a digital representation of the reservoir, predicting the distribution of fluids and identifying areas with high hydrocarbon saturation.

By leveraging these technologies, operators can pinpoint the most promising zones within the reservoir, ensuring that infill wells target areas with the greatest potential for unlocking additional reserves.

- Well Placement Optimization: Once potential target zones are identified, the placement of infill wells becomes critical. This requires sophisticated wellbore planning software that can simulate various well configurations within the reservoir model. Factors like:

- Well Spacing: Finding the optimal balance between maximizing reservoir contact and minimizing drilling costs is essential. Placing wells too close together can lead to well interference, while excessive spacing can leave behind bypassed hydrocarbons.

- Directional Drilling Techniques: Advanced drilling techniques like horizontal and multilateral wells allow for greater reservoir contact, reaching previously unreachable areas and maximizing hydrocarbon recovery.

Through meticulous wellbore planning software simulations, operators can identify the configuration that delivers the highest production gain while considering cost-effectiveness and wellbore stability.

- Wellbore Design and Completion Strategies: Choosing the right wellbore design and completion techniques directly impacts the efficiency and performance of infill wells. Important factors include:

- Wellbore Trajectory: The planned path of the wellbore plays a crucial role in maximizing reservoir contact within the targeted zone.

- Completion Techniques: Selecting the appropriate completion methods, such as perforation strategies and downhole equipment, ensures optimal flow of hydrocarbons from the reservoir into the wellbore.

By carefully considering these factors, operators can ensure that infill wells are designed and completed to deliver optimal production performance throughout their lifespan.

Advanced Techniques for Strategic Infill Drilling

The oil and gas industry is constantly innovating, developing cutting-edge technologies that push the boundaries of what’s achievable with strategic infill drilling. These advancements allow for more precise well placement, real-time reservoir monitoring, and data-driven optimization, leading to significantly improved recovery rates.

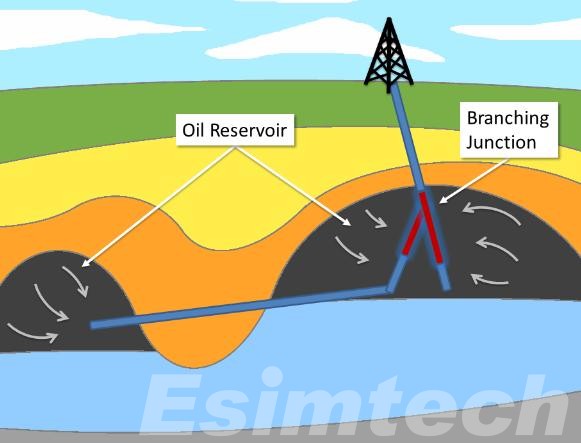

Horizontal and Multilateral Wells

Traditional vertical wells can only access a limited portion of the reservoir. Horizontal and multilateral wellbore configurations offer a game-changing solution. Horizontal wells extend for long distances within the reservoir, maximizing contact with hydrocarbon-rich zones. Multilateral wells branch out from a single wellbore, reaching into multiple sections of the reservoir, further increasing the drainage area. These advanced wellbore techniques allow operators to target previously unreachable pockets of hydrocarbons, significantly boosting overall recovery.

Real-time Reservoir Monitoring

Downhole sensors placed within infill wells provide a constant stream of valuable data on reservoir pressure, temperature, and fluid flow dynamics. This real-time data allows for:

- Dynamic Production Adjustments: By monitoring pressure changes and fluid flow patterns, operators can make adjustments to production and injection strategies on the fly. This dynamic approach ensures optimal well performance and maximizes recovery throughout the life of the infill well.

- Improved Reservoir Characterization: The continuous flow of data from downhole sensors helps to refine the understanding of the reservoir’s behavior. This ongoing characterization allows for adjustments to the reservoir model, leading to more accurate predictions of remaining reserves and optimizing future infill well placements.

Advanced Data Analytics and Machine Learning

The vast amount of data generated by seismic surveys, wellbore logs, production history, and downhole sensors can be harnessed through advanced data analytics and machine learning algorithms. These powerful tools can:

- Identify Production Sweet Spots: By analyzing complex datasets, machine learning can identify areas within the reservoir with the highest concentration of recoverable hydrocarbons, guiding infill well placement with exceptional precision.

- Predict Future Reservoir Behavior: Machine learning algorithms can analyze historical production data and reservoir characteristics to predict future behavior. This predictive capability allows for proactive well management strategies, ensuring optimal production performance throughout the lifespan of the reservoir.

Drilling Simulation Technology

Before committing to real-world drilling operations, sophisticated drilling simulators can be utilized to test and refine infill well plans. These simulators create realistic virtual environments that replicate the complexities of the reservoir and wellbore conditions. By virtually drilling infill wells in the simulator, engineers can:

- Optimize Wellbore Trajectories: Simulators allow for testing various wellbore paths to identify the trajectory that maximizes reservoir contact and minimizes drilling risks.

- Evaluate Wellbore Stability Issues: The simulator can predict potential wellbore instability problems, such as formation collapse or pressure surges, allowing for adjustments to drilling plans and wellbore design to ensure safe and efficient drilling operations.

- Train Drilling Crews: Drilling simulators provide a safe and controlled environment for crews to train on specific wellbore scenarios, familiarizing them with the challenges and procedures involved in drilling infill wells within a particular reservoir.

By utilizing these advanced techniques, operators can unlock the full potential of strategic infill drilling. From precisely targeting untapped reserves to dynamically optimizing production based on real-time data, these advancements are transforming the way mature reservoirs are managed, leading to a significant increase in ultimate recovery rates and maximizing the economic value of these valuable assets.

Conclusion

Strategic infill drilling breathes new life into maturing reservoirs. Advanced techniques unlock trapped reserves, extending field life and boosting profitability. This approach offers a sustainable and cost-effective solution for maximizing resource recovery. As technology advances, strategic infill drilling will continue to play a vital role in the future of the oil and gas industry.