Logging While Drilling Applications in Shale Gas Development

Shale gas, a natural gas trapped within shale rock formations, has emerged as a significant energy source in recent years. Its extraction involves drilling horizontal wells into shale formations and then using hydraulic fracturing to release the gas. To ensure efficient and profitable shale gas development, operators rely on advanced technologies, including logging while drilling (LWD).

What is Logging While Drilling?

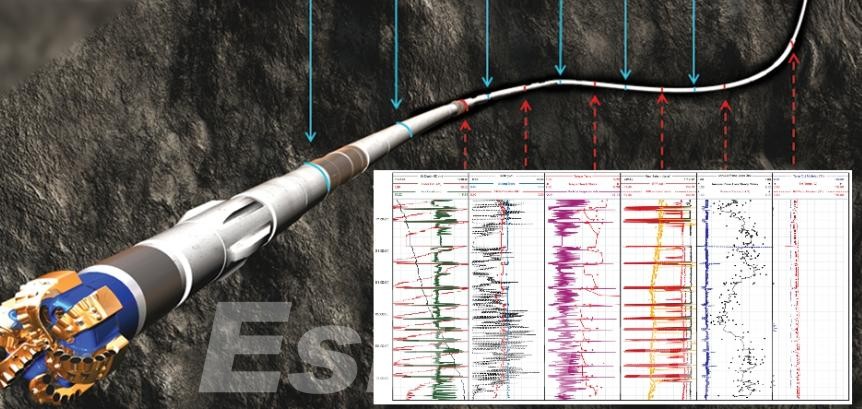

Logging while drilling (LWD) is a downhole measurement technique that collects real-time data while a drilling rig is operating. It involves placing sensors and tools on the bottom of the drill string, allowing for continuous monitoring of the borehole environment. This technology provides insights into geological formations, reservoir properties, and drilling conditions.

Key Technologies Used in Logging While Drilling

Logging While Drilling (LWD) technologies are crucial for real-time formation evaluation and decision-making during drilling operations. Key technologies used in LWD include Gamma Ray Logging, Resistivity Tools, Sonic Logging, and Density Tools, each providing vital information about subsurface conditions.

- Gamma Ray Logging measures the natural gamma radiation emitted from rock formations. This radiation is primarily from the decay of potassium, uranium, and thorium, which are found in varying concentrations in different rock types. By analyzing this radiation, geologists can identify lithology (rock types) and correlate formations across multiple wells, aiding in the accurate mapping of subsurface geology.

- Resistivity Tools measure the electrical resistance of the rock formations. This data is crucial for assessing fluid saturation levels within the rock. Lower resistivity typically indicates the presence of conductive fluids like water, while higher resistivity suggests hydrocarbon-bearing zones. This helps in identifying potential zones of interest for hydrocarbon production.

- Sonic Logging involves sending sound waves through the formation and measuring their velocity. The velocity of these waves is influenced by the rock’s porosity and strength. By analyzing sonic velocities, geologists can infer rock porosity, which is vital for understanding fluid storage capacities and the mechanical properties of the formation.

- Density Tools measure the bulk density of the rock. When combined with other data, such as sonic and gamma ray logs, density measurements help in determining the porosity of the rock and evaluating its lithology. This information is essential for accurate reservoir characterization and effective drilling strategies.

Together, these LWD technologies provide a comprehensive view of the subsurface environment, enabling more informed and efficient drilling decisions.

Key Applications of LWD in Shale Gas Development

Logging while drilling (LWD) plays a pivotal role in shale gas development, providing critical information for optimizing drilling operations and maximizing gas recovery. Here are some of the key applications of LWD in this context:

Formation Evaluation

- Porosity and permeability measurements: LWD tools can accurately measure porosity and permeability, which are essential for determining the reservoir’s ability to store and produce gas. Porosity is a measure of the pore space in the rock, while permeability is a measure of the rock’s ability to allow fluids to flow through it.

- Mineralogy and lithology identification: By analyzing the composition of the shale formation, LWD can help identify potential sweet spots with higher gas content and lower clay content. Clay minerals can reduce permeability and hinder gas flow, while organic matter is the source of the gas.

- Organic matter content assessment: LWD tools can measure the amount of organic matter present in the shale, which is directly related to the gas content. Organic matter is the source of the hydrocarbons that are trapped in the shale formation.

Real-Time Drilling Optimization

- Drilling parameter monitoring: LWD provides real-time data on drilling parameters such as weight on bit, rotary speed, and torque, allowing operators to optimize drilling efficiency and minimize equipment wear and tear. Weight on bit is the force exerted by the drill bit on the formation, while rotary speed is the rate at which the drill string rotates. Torque is the twisting force applied to the drill string.

- Bit life monitoring: LWD can help track the performance of drill bits, allowing operators to replace them before they become worn out and cause drilling delays. This can help reduce non-productive time and improve drilling efficiency.

- Hole cleaning assessment: LWD can monitor the effectiveness of hole cleaning operations, ensuring that cuttings are efficiently removed from the borehole to prevent borehole instability and improve drilling efficiency. Cuttings are the fragments of rock that are generated during drilling, and they can accumulate in the borehole and cause problems if they are not removed.

Wellbore Stability

- Borehole diameter measurement: LWD can accurately measure the borehole diameter, helping to identify potential borehole stability issues such as washouts or cavings. Washouts are erosions in the borehole wall, while cavings are pieces of rock that break off and fall into the borehole.

- Formation pressure monitoring: LWD can measure formation pressure, allowing operators to optimize drilling fluid properties to prevent wellbore collapse or kicks. Formation pressure is the pressure exerted by the fluids in the formation on the borehole wall. A kick occurs when formation fluids flow into the borehole, which can be dangerous if not managed properly.

- Mud filtrate invasion monitoring: LWD can monitor the invasion of drilling fluid filtrate into the formation, which can affect wellbore stability and reservoir properties. Filtrate is the liquid component of the drilling fluid that can invade the formation and reduce its permeability.

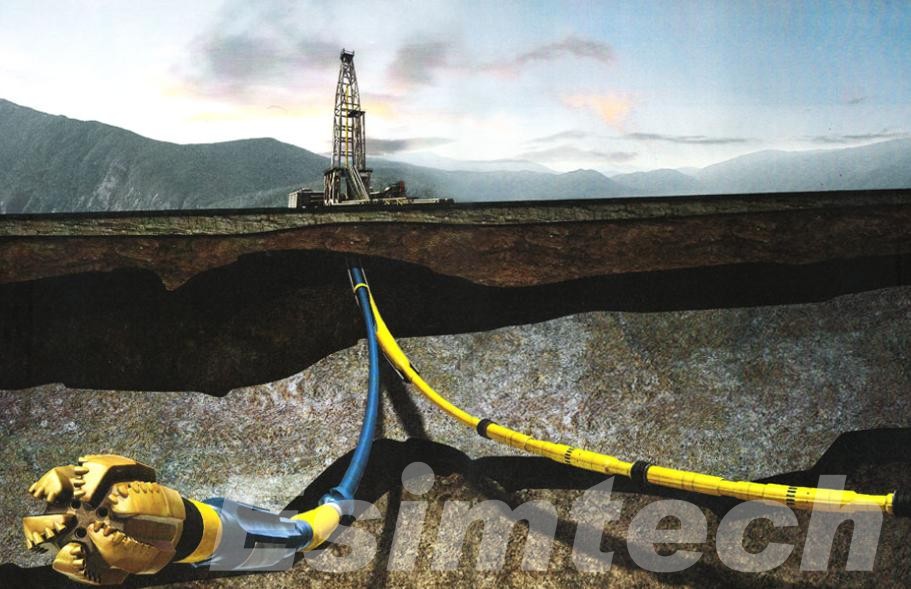

Horizontal Drilling Guidance

- Wellbore trajectory measurement: LWD tools can accurately measure the wellbore trajectory, ensuring that the drill bit stays on target and avoids encountering faults or other geological features that could disrupt drilling operations. A fault is a fracture in the Earth’s crust along which rocks have slipped relative to each other.

- Directional drilling control: LWD data can be used to adjust the drilling trajectory in real time, ensuring that the well is drilled in the desired direction. This is particularly important for horizontal wells, which are drilled at an angle to reach the target shale formation.

Reservoir Characterization

- Reservoir property mapping: LWD data can be used to create detailed maps of reservoir properties, such as porosity, permeability, and organic matter content. This information can be used to optimize production strategies and maximize gas recovery.

- Fracture identification: LWD can help identify natural fractures in the shale formation, which can enhance gas production. Fractures can provide pathways for gas to flow to the wellbore.

- Reservoir simulation: LWD data can be used to calibrate reservoir simulation models, which are essential for optimizing production strategies. Reservoir simulation models are computer programs that simulate the flow of fluids through the reservoir.

By providing real-time data on these key aspects of shale gas development, LWD enables operators to make informed decisions, optimize drilling operations, and maximize gas recovery.

Benefits of Using LWD in Shale Gas Development

Logging While Drilling (LWD) offers several key advantages in shale gas development. By providing real-time data and insights during the drilling process, LWD enhances efficiency, accuracy, and safety, while also contributing to cost savings and better reservoir management.

- Enhanced Drilling Efficiency: Real-time data from LWD allows for immediate adjustments to drilling parameters, reducing downtime and speeding up well completions.

- Increased Accuracy: Direct measurements from the wellbore minimize uncertainties in subsurface evaluations, helping to accurately target productive zones and reduce the risk of dry wells.

- Cost Savings: The ability to make informed decisions in real time lowers the likelihood of costly mistakes and reduces the need for corrective actions, leading to lower drilling costs and a higher return on investment.

- Improved Safety: Continuous monitoring of well conditions and formation properties helps in the early detection of potential hazards, enhancing overall safety by mitigating risks like wellbore instability and blowouts.

- Optimized Reservoir Management: Real-time insights from LWD enable better decision-making regarding well placement, fracturing techniques, and production strategies, leading to more effective reservoir management and improved resource recovery.

In summary, Logging While Drilling is a transformative technology in shale gas development, offering critical advantages such as enhanced efficiency, improved accuracy, cost savings, safety improvements, and better reservoir management. As the demand for shale gas continues to grow, the integration of LWD into drilling operations will play an increasingly vital role in optimizing production and maximizing resource potential.