Key Effective Methods for Oil Reservoir Management

Oil reservoir management is a crucial aspect of the petroleum industry, focusing on the efficient and sustainable extraction of hydrocarbons from underground reservoirs. It encompasses a variety of techniques, strategies, and technologies aimed at maximizing recovery while minimizing operational costs. Effective reservoir management is vital for extending the life of an oil field and optimizing production over time.

The Fundamentals of Oil Reservoir Management

At its core, oil reservoir management involves the coordinated and continuous optimization of production strategies to maximize the amount of recoverable oil and gas from a reservoir. It integrates geological, geophysical, and engineering data to make informed decisions on the best ways to develop and deplete oil fields. The ultimate goal is to achieve the highest possible recovery factor that often a small percentage of the total oil-in-place while minimizing operational costs and environmental risks.

Key Components of Oil Reservoir Management

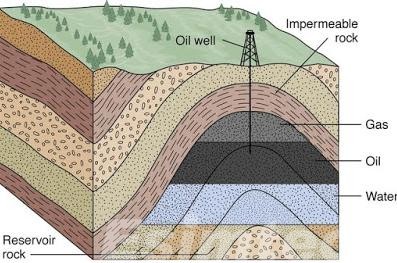

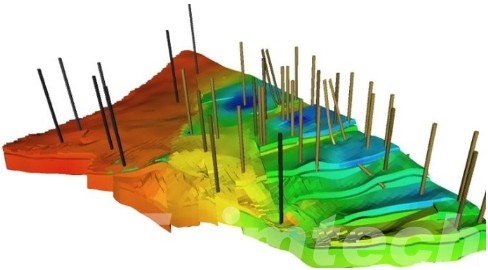

1. Reservoir Characterization

Reservoir characterization involves the detailed analysis of the reservoir’s geological, geophysical, and petrophysical properties. Understanding the reservoir’s porosity, permeability, fluid saturation, and structural complexities is critical for designing appropriate recovery strategies. Techniques such as core sampling, well logging, and 3D seismic imaging are commonly used to assess the reservoir’s characteristics.

Key Tools: 3D/4D seismic imaging, well logging, core analysis, geological modeling.

2. Production Optimization

Optimizing production involves managing the extraction process to maximize oil and gas output while minimizing operational costs and downtime. This includes monitoring well performance, adjusting production rates, and implementing techniques like artificial lift or well stimulation (e.g., hydraulic fracturing). Continuous evaluation of well conditions ensures the reservoir operates efficiently and that declining production is addressed promptly.

Key Techniques: Artificial lift (e.g., electric submersible pumps), well stimulation, hydraulic fracturing, production logging.

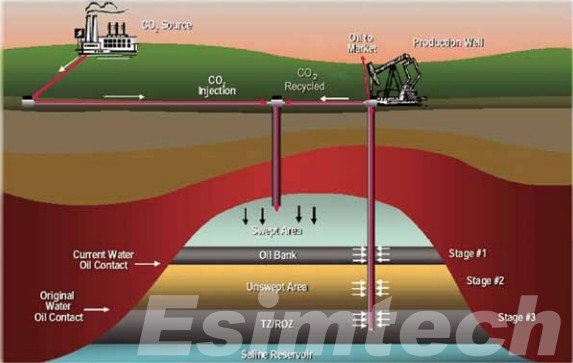

3. Pressure Maintenance and Secondary Recovery

Maintaining reservoir pressure is essential to sustaining production and improving recovery rates. As production proceeds, reservoir pressure naturally declines, leading to reduced oil flow. Pressure maintenance can be achieved through waterflooding or gas injection, techniques that involve injecting water or gas into the reservoir to maintain pressure and push oil toward production wells.

Key Techniques: Waterflooding, gas injection (natural gas, CO2).

4. Enhanced Oil Recovery (EOR)

Enhanced Oil Recovery (EOR) techniques are applied when primary and secondary recovery methods are insufficient to extract the remaining oil. EOR involves injecting chemicals, gases, or heat into the reservoir to improve oil displacement. It is often implemented in mature reservoirs where conventional methods can no longer produce economically viable volumes of oil.

Key Techniques: Chemical injection (polymers, surfactants), thermal recovery (steam injection), gas injection (CO2, nitrogen).

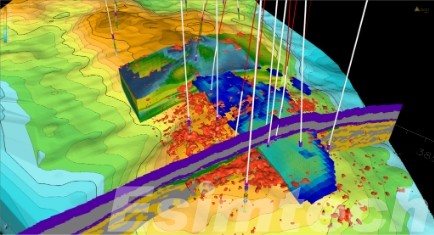

5. Reservoir Monitoring and Data Integration

Real-time monitoring and data integration are critical for making informed decisions about reservoir management. Advanced technologies such as permanent downhole sensors, 4D seismic surveys, and pressure and temperature gauges provide continuous data about the reservoir’s condition. This data is used to update models and optimize recovery strategies as the reservoir depletes.

Key Tools: Downhole sensors, real-time data analytics, 4D seismic surveys, permanent pressure and temperature monitoring.

6. Water and Gas Management

Managing the water and gas produced along with oil is an important element of reservoir management. Water management is critical in waterflooding operations to prevent issues like early water breakthrough, which can reduce oil recovery efficiency. Similarly, handling associated gas—either through reinjection or flaring—helps maintain pressure and improve recovery.

Key Techniques: Waterflood control, gas reinjection, produced water management.

7. Geomechanics and Reservoir Integrity

Understanding the geomechanical properties of the reservoir is essential to avoid issues such as subsidence, compaction, or fault reactivation. These issues can cause wellbore instability, reduce productivity, and even lead to environmental hazards. Geomechanical modeling helps optimize well placement, completion design, and pressure management.

Key Tools: Geomechanical modeling, stress analysis, wellbore stability assessment.

8. Sustainability and Environmental Considerations

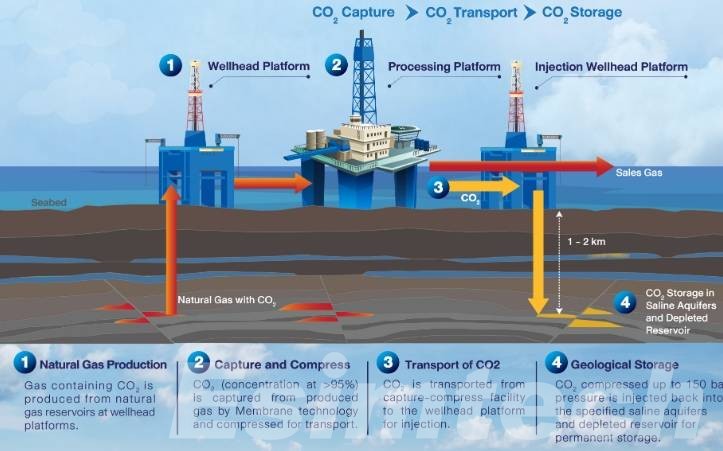

Modern reservoir management must prioritize sustainability and minimize the environmental impact of production activities. This involves reducing emissions, managing water use effectively, and implementing Carbon Capture and Storage (CCS) solutions. Sustainability practices can also improve the public perception of oil and gas operations and ensure regulatory compliance.

Key Practices: Carbon capture and storage (CCS), produced water recycling, and energy efficiency initiatives.

Challenges in Oil Reservoir Management

This chart outlines the major challenges faced in oil reservoir management and their impact on operations.

| Challenge | Description | Impact on Reservoir Management |

| Reservoir Heterogeneity | Variability in rock properties (porosity, permeability) within the reservoir leads to uneven fluid flow and recovery. | Difficulty in predicting fluid movement, inefficient recovery, and increased production costs. |

| Uncertainty in Reservoir Data | Incomplete or inaccurate reservoir data results in unreliable models and forecasts. | Leads to suboptimal well placement, poor recovery strategies, and financial losses. |

| Water and Gas Breakthrough | Premature water or gas intrusion into the production wells reduces oil recovery efficiency. | Results in lower oil recovery rates and increased water/gas handling costs. |

| Pressure Maintenance | Maintaining reservoir pressure is critical for sustained production, but pressure depletion can lead to reduced flow rates. | Decreased recovery efficiency and early field abandonment. |

| Complex Fluid Behavior | Nonlinear behavior of oil, gas, and water phases, especially in unconventional reservoirs, complicates flow predictions. | Impacts recovery strategies and makes fluid behavior hard to simulate. |

| Wellbore Integrity | Wellbore failures due to mechanical issues or reservoir pressure changes can disrupt production. | Risk of production delays, environmental hazards, and increased operational costs. |

| Enhanced Oil Recovery (EOR) Complexity | Implementation of EOR methods like gas or chemical injection can be technically challenging and expensive. | High operational costs and uncertainty regarding the success of EOR techniques. |

| Reservoir Compaction and Subsidence | Overproduction can lead to reservoir rock compaction and surface subsidence, causing environmental and operational problems. | Reduced reservoir porosity and permeability, risk to surface infrastructure. |

| Environmental Regulations | Compliance with stringent environmental regulations impacts operations, especially in sensitive areas. | Increases in operational costs and limitations on production activities. |

| Economic Volatility | Fluctuations in oil prices and market conditions affect long-term investment and operational decisions. | Reduced profitability, delayed projects, and operational cutbacks. |

Emerging Trends in Oil Reservoir Management

The evolution of oil reservoir management is being shaped by technological advancements and environmental considerations to address the challenges in reservoir management.

1. Digitalization and Automation

The digital transformation in the oil and gas sector has introduced cutting-edge tools such as automation, artificial intelligence (AI), machine learning (ML), and big data analytics into reservoir management. These technologies allow for better decision-making by providing real-time insights and predictive models for reservoir behavior.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are used to analyze large sets of reservoir data, providing insights into fluid flow, pressure variations, and other critical factors. These tools help optimize production strategies, predict equipment failures, and reduce operational costs.

- Automation: The use of automated systems for remote monitoring and control of wells helps in improving safety, reducing downtime, and ensuring precision in reservoir management.

2. Advanced Enhanced Oil Recovery (EOR) Techniques

Enhanced Oil Recovery (EOR) methods continue to evolve, with new technologies emerging to extract more hydrocarbons from mature or difficult reservoirs.

- Nanotechnology in EOR: Nanoparticles are being developed to improve fluid mobility in the reservoir, enhance oil displacement, and reduce surface tension between oil and water. Nanotechnology also has applications in monitoring fluid flow and improving the efficiency of chemical EOR methods.

- Smart Waterflooding: Smart waterflooding is an advanced version of traditional waterflooding, where the chemical composition of the injection water is optimized to enhance oil displacement. By adjusting salinity and ionic composition, operators can significantly improve oil recovery.

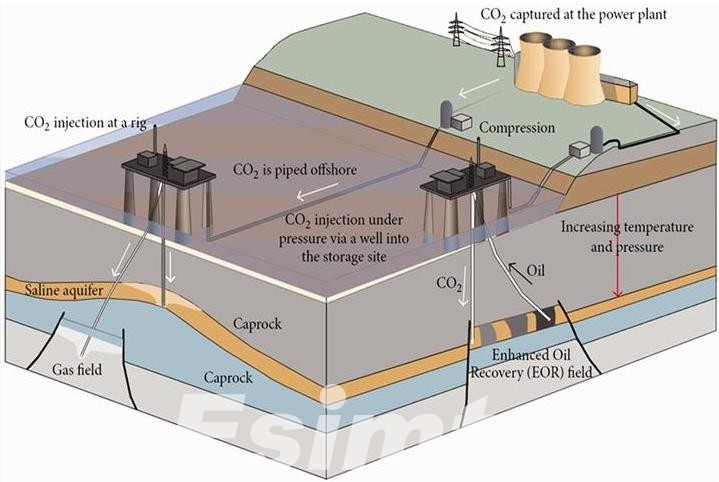

- Carbon Dioxide (CO2) Injection: CO2 EOR continues to gain traction as an effective method to recover residual oil while also reducing greenhouse gas emissions. Injected CO2 helps increase oil mobility and improves sweep efficiency, while also serving as a means for carbon capture and storage (CCS).

3. Carbon Capture, Utilization, and Storage (CCUS)

Carbon Capture, Utilization, and Storage (CCUS) is emerging as a dual-purpose technology for improving oil recovery while reducing carbon emissions. By injecting CO2 into oil reservoirs, operators can not only enhance oil recovery but also sequester CO2, thus reducing the carbon footprint of oil production.

- CCUS Integration with EOR: Many oil fields are now integrating CCUS with traditional EOR techniques, where captured CO2 from industrial emissions is injected into the reservoir. This allows operators to boost oil production while meeting climate targets by permanently storing CO2 underground.

- Regulatory Support: Increasing government incentives and carbon credits for CCUS projects are encouraging companies to adopt this technology on a larger scale.

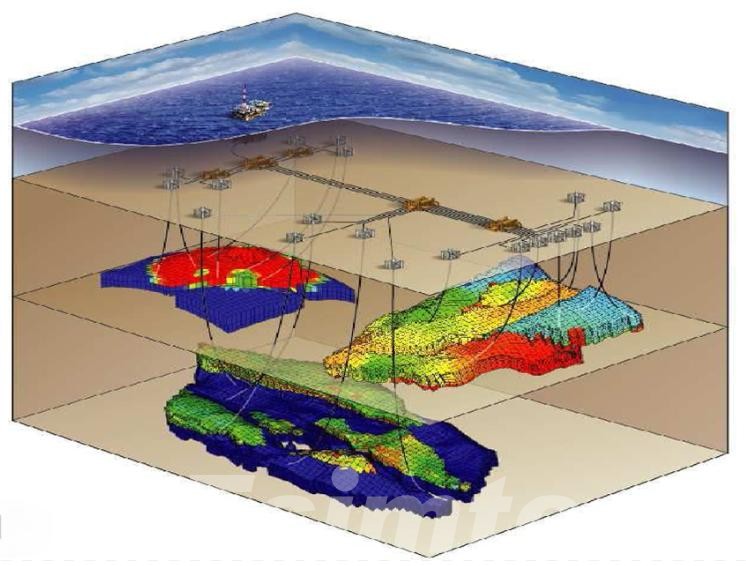

4. Integrated Reservoir Management (IRM)

The concept of Integrated Reservoir Management (IRM) emphasizes a holistic approach that combines geological, geophysical, and engineering disciplines to manage reservoirs more effectively. By integrating data from various sources and departments, operators can make better decisions about drilling, production optimization, and reservoir depletion.

- Cross-Disciplinary Collaboration: IRM encourages collaboration among geologists, reservoir engineers, and data scientists to create comprehensive management strategies that optimize recovery while minimizing risk.

- Integrated Data Platforms: The development of cloud-based platforms that aggregate and analyze data from various sensors, wells, and models allows for seamless collaboration and real-time updates, improving decision-making and operational efficiency.

5. Sustainable Reservoir Management

Sustainability is becoming a central focus in reservoir management, driven by the need to reduce environmental impact, comply with regulations, and meet global energy transition goals.

- Energy-Efficient Operations: Many oil companies are adopting energy-efficient equipment and processes to reduce emissions and energy consumption during reservoir operations. This includes using renewable energy sources like solar or wind to power production facilities.

- Green Reservoir Management Practices: Reservoir management strategies now incorporate practices like reducing water consumption, recycling produced water, and minimizing methane emissions during production.

- Biosurfactants in EOR: Biosurfactants, which are environmentally friendly surfactants derived from natural sources, are gaining popularity in chemical EOR applications. They help reduce the environmental footprint of recovery processes and improve oil displacement in reservoirs.

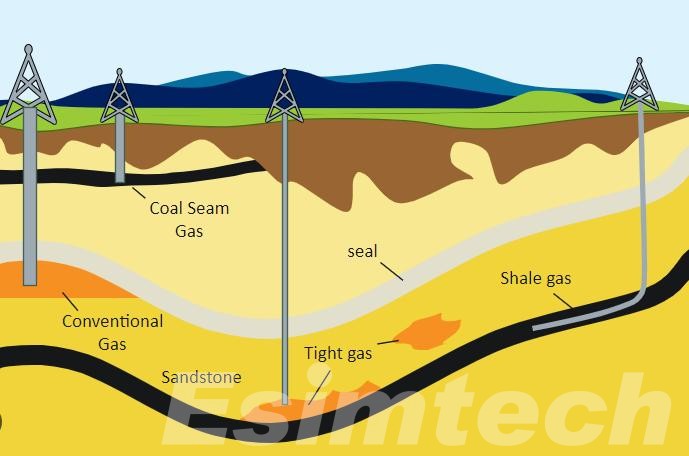

6. Unconventional Reservoir Management

As the industry continues to tap into unconventional oil and gas resources such as shale and tight formations, new techniques for managing these reservoirs are emerging.

- Fracture Diagnostics: In unconventional reservoirs, hydraulic fracturing is the key method for accessing hydrocarbons. Advanced fracture diagnostics, such as microseismic monitoring and fiber-optic sensing, are being used to better understand fracture geometry and optimize fracturing operations.

- Geomechanical Modeling for Shale: In unconventional fields, understanding the geomechanical behavior of the rock formation is critical. Advanced geomechanical models help predict how reservoirs will react to hydraulic fracturing, ensuring that operators can extract hydrocarbons safely and efficiently.

7. Artificial Lift Optimization

Artificial lift systems, such as electric submersible pumps (ESPs) and gas lift systems, are being optimized using AI and IoT-enabled sensors for better performance and cost savings.

- Smart Lift Systems: Smart artificial lift systems incorporate real-time monitoring, remote control, and AI-driven algorithms to adjust pump rates and optimize well performance based on reservoir conditions.

- Data-Driven Lift Optimization: Advanced data analytics are used to identify inefficiencies in lift operations, predict maintenance needs, and optimize the lifespan of artificial lift equipment.

Key Simulation Technologies Used for Effective Oil Reservoir Management

This chart highlights the core simulation technologies used in oil reservoir management as well as their applications.

| Simulation Technology | Description | Key Applications |

| Reservoir Simulation Software | Numerical models simulate fluid behavior in the reservoir, forecasting production and optimizing recovery. | Black oil models, compositional simulation, thermal recovery, well placement optimization. |

| Dynamic Reservoir Modeling (4D) | Incorporates time into reservoir models to track changes over time. | 4D seismic for monitoring fluid movement, time-lapse data integration for enhanced oil recovery (EOR) projects and mature fields. |

| Geomechanical Simulation | Models rock mechanics and stress to ensure wellbore stability and prevent subsidence or fault reactivation. | Wellbore stability analysis, fracture propagation, stress field analysis, hydraulic fracturing optimization. |

| Fluid Flow Simulation | Simulates multiphase flow dynamics and optimizes well spacing and injection rates. | Multiphase flow simulation, coupled reservoir and surface network simulation, transient flow simulation for production strategies. |

| History Matching | Adjusts simulation models to match historical production data for accurate forecasting. | Automated history matching, integration of production, pressure, and seismic data to refine reservoir models and improve accuracy. |

| Real-Time Reservoir Monitoring | Uses real-time data from sensors for continuous model updating and dynamic adjustment of strategies. | Permanent downhole sensors, digital oilfields integrating sensor data with simulation, AI-driven predictions for optimizing production in real-time. |

| Fracture Simulation | Models behavior of fractures and their influence on fluid flow for unconventional and fractured reservoirs. | Dual-porosity models, discrete fracture networks (DFN), optimized well placement and recovery strategies in naturally fractured reservoirs. |

| Uncertainty Analysis | Evaluates risk by simulating a range of potential outcomes and identifying key uncertainties. | Probabilistic simulations, sensitivity analysis for better data collection and reducing uncertainty in reservoir behavior and production. |

Oil reservoir management is at the heart of ensuring the optimal recovery of hydrocarbons from increasingly complex reservoirs. With advancements in digital technology, EOR method and sustainability practices, reservoir management is evolving to meet the demands of modern energy production. By continuously adapting to new challenges, the innovative solutions can maximize recovery while minimizing environmental impact, driving efficiency and profitability for oil and gas companies.