Innovations in Underbalanced Drilling Equipment

Underbalanced drilling (UBD) has emerged as a critical technique in the oil and gas industry, offering significant advantages in terms of reduced formation damage, increased drilling rates, and lowered operational costs. This article delves into the latest advancements and innovations in underbalanced drilling equipment that are transforming the industry.

What is Underbalanced Drilling

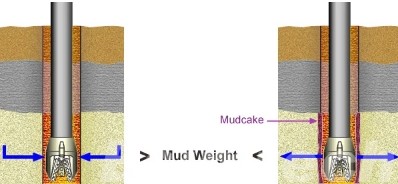

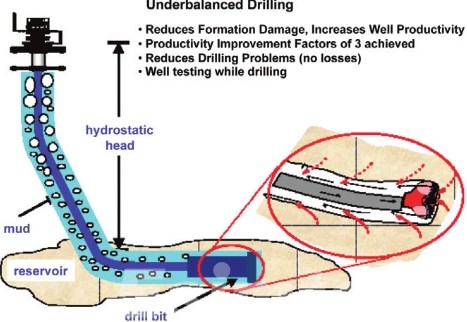

Underbalanced drilling is a sophisticated drilling technique used in where the pressure inside the wellbore is intentionally maintained below the pressure of the formation being drilled, which is achieved by using lighter drilling fluids, such as air, mist, foam, or a combination of these, instead of the traditional heavier muds.

The key benefits of underbalanced drilling include:

- Minimized Formation Damage: By reducing the pressure differential between the wellbore and the formation, the risk of damaging the formation with excessive fluid invasion is decreased.

- Enhanced Drilling Rates: The reduced pressure allows for faster drilling rates as there is less resistance from the formation.

- Improved Reservoir Access: Underbalanced drilling can help in accessing hard-to-reach reservoirs by maintaining the integrity of the formation during the drilling process.

- Reduced Operating Costs: The use of lighter fluids can lower the overall cost of drilling operations compared to traditional methods.

- Environmental Considerations: UBD drilling can be more environmentally friendly as it reduces the volume of waste fluids that need to be disposed of.

However, underbalanced drilling requires advanced well control measures and specialized equipment to handle the lighter fluids and it poses increased risks of wellbore instability and gas influx.

Common Used Traditional Underbalanced Drilling Equipment

This chart provides an overview of the common traditional equipment used in underbalanced drilling, with each type serving a specific function and application scenario. The selection and configuration of these devices depend on the specific drilling requirements and reservoir characteristics.

| Equipment Type | Description | Remarks |

| Drilling Rigs | Includes drill pipes or coiled tubing, determined by well size and trajectory. | Coiled tubing is suitable for wells up to 6⅛ inches, while larger wells may require drill pipes. |

| Gas Generation Equipment | Includes natural gas compressors, liquid nitrogen supply, and nitrogen generators. | Used to provide the necessary gas for underbalanced drilling, such as air or nitrogen. |

| Well Control Equipment | Includes blowout preventers (BOPs), rotating control head systems, and emergency shut-off valves. | Used to control downhole pressure to prevent blowouts. |

| Surface Separation Equipment | Used to separate oil, gas, water, and solids, including four-phase separation systems. | Must be custom-designed based on expected reservoir fluids. |

| Rotating Control Heads (Passive Systems) | Passive sealing systems used to maintain downhole pressure below reservoir pressure. | Suitable for air and foam drilling applications, with clear pressure limitations. |

| Rotating Blowout Preventers (Active Systems) | Enable underbalanced drilling using drill pipes in various reservoir and wellbore scenarios. | The size and selection of the rotating control head system are determined by expected surface pressure. |

| Grease Injection Systems | If underbalanced tripping (hoisting or lowering) is required, it must be installed above the rotating control head system. | Used to maintain pressure control in the wellbore during tripping operations. |

| Rotating Diverter Systems | Provide effective annular sealing around the drill pipe to accommodate different pressures and operational procedures. | Include both active and passive types of rotating diverters. |

Latest Advancements in Underbalanced Drilling Equipment

1. Advanced Rigs and Equipment

One of the key innovations in UBD drilling is the development of efficient and mobile rigs, as highlighted in a study focusing on the progress. These drilling rig equipment are designed to handle the specific challenges of deep and ultra-deep well drilling, including high temperatures, high pressures, and narrow pressure windows. The development of quadruple-joint-stand rigs and automatic pipe handling devices for rigs drilling wells up to 7000 meters deep represents a significant step forward in UBD drilling equipment technology.

2. Intelligent Drilling Optimization

Artificial intelligence (AI) is playing an increasingly prominent role in UBD drilling. An intelligent drilling optimization application, as mentioned in a 2020 study, acts as an adaptive autodriller. This novel technology uses AI algorithms to enhance on-bottom drilling performance, reduce the dependence on human intervention, and lower the risk of slow or incorrect responses in drilling dysfunction. Field applications have shown an improvement in the rate of penetration (ROP) by 61% and drilling performance by 25%.

3. High-Performance Drill Bits and Downhole Tools

The evolution of drilling technologies also includes advancements in high-performance drill bits and auxiliary tools. The Steer-At-Bit Enteq Rotary Tool (SABER) is an example of an innovative tool that uses internally directed pressure differentials for true “at-bit” geosteering, offering a robust and cost-effective alternative to traditional rotary steerable systems (RSS). Additionally, Haliburton’s iCruise is an intelligent push-the-bit RSS that enables improved steerability and drilling performance, reducing well time through faster drilling and reliable performance.

4. Managed Pressure Drilling Systems

Managed pressure drilling (MPD) systems are becoming increasingly integrated with UBD practices. MPD systems help maintain wellbore pressure control, which is crucial for preventing wellbore instability and lost circulation. The integration of MPD with UBD allows for a more controlled approach to underbalanced operations, enhancing safety and efficiency.

5. Foamed Drilling Fluids

Innovations in underbalanced drilling also extend to drilling fluids. A review of UBD drilling techniques highlights the advancement of foamed drilling fluids, which can reduce formation damage and provide better clean-up and cuttings lift capacity. Foam drilling fluids are categorized into stable foam, stiff foam, and oil foam, with stiff foam being the most common due to its ability to lift more cuttings and stabilize the borehole.

6. Real-Time Data Analytics and Automation

The combination of live drilling data streams with cloud data analytics pipelines enables real-time automated projections to the bit. This technology allows for more informed decision-making during drilling operations, leading to increased productivity and reduced non-productive time (NPT).

How Simulation Tools are Used for the Innovative Underbalanced Drilling Equipment

The simulation tools help in understanding the complex dynamics of drilling operations, optimizing performance, and ensuring safety.

- Dynamic Drilling Simulation: The dynamic drilling simulations for pressure control, well control, blowout control, managed, and underbalanced operations. It replicates real drilling operations with accuracy not possible with simpler steady-state models. The simulation tool is built around the well-control workflow and provides features like transient temperature, full compositional tracking, advanced PVT modeling, and fully transient including acceleration effects .

- Finite Element Method (FEM): The FEM is widely used in geotechnical research as an effective tool for assessing stress and strain status in underbalanced drilling operations. It helps in determining the necessary weight of drilling mud for the entire field by analyzing a single well, which is crucial for wellbore stability analysis .

- Nonlinear Moving Horizon Estimation (MHE): This method is used for state estimation of the underbalanced drilling system in the presence of parametric uncertainties. It estimates the production indices of oil and gas from the reservoir into the well under manual and automatic control conditions. The performance of the nonlinear MHE is compared with the Unscented Kalman Filter (UKF) for states and parameters estimation, showing its high performance in identifying production indices and diagnosing rapid variations in production conditions .

- Two-Fluid Model of Two-Phase Flow: This model is used to simulate underbalanced drilling operations, particularly important for accurately predicting bottom-hole pressure (BHP) and other parameters of two-phase flow. The model can accurately predict BHP and other two-phase flow parameters, making it a valuable tool for UBD operations.

- Model Predictive Control (MPC): This is a novel application for pressure and flow control in underbalanced drilling equipment. It uses coordinated control of pump flow and choke pressure to control the return flow rate and the well pressure profile. The control system is verified using a high fidelity drilling simulator for common drilling operations, showing promising results for operations close to the selected set-points.

- Wellbore Stability Simulations: Simulations are performed to establish the feasibility of using underbalanced drilling equipment in highly depleted reservoirs. The in-situ stress field and the mechanical properties of the formation were obtained, and the analysis showed that horizontal wells could be drilled in an underbalanced condition with low instability risk.

Overall, the innovations in underbalanced drilling equipment are driving efficiency and safety in the oil and gas industry. These technologies are not only improving operational outcomes but also setting new standards for sustainable drilling practices. From well control and pressure management to the optimization of drilling parameters and the prediction of wellbore stability. Simulation tools are essential in ensuring the safety and efficiency of UBD drilling operations.