Innovations in Drilling Mud Systems Tailored for Top Drive Drilling

As drilling environments become more complex, the demand for innovative drilling mud systems that can seamlessly integrate with top-drive drilling technology has grown. These innovations are essential to maintaining drilling fluid integrity, optimizing wellbore stability, and ensuring effective cuttings transport.

The Critical Role of Drilling Mud Systems in Top Drive Drilling

Here’s a chart outlining the critical functions of drilling mud systems in top drive drilling and underscores their significance in maintaining efficiency, safety, and environmental compliance.

| Role of Drilling Mud Systems | Description | Importance in Top Drive Drilling |

| Wellbore Stability and Pressure Control | Maintains wellbore integrity by balancing formation pressures and preventing blowouts or collapses. | Essential for preventing wellbore instability, especially in deep and complex wells commonly drilled with top drive systems. |

| Cuttings Transport and Hole Cleaning | Suspends and carries drill cuttings to the surface, preventing blockages and ensuring a clean wellbore. | Critical for maintaining a steady drilling pace and preventing issues like stuck pipe in high-angle or horizontal wells. |

| Lubrication and Friction Reduction | Reduces friction between the drill string and the wellbore, minimizing torque, drag, and the risk of a stuck pipe. | Vital for smooth operation of the continuously rotating drill string in top drive systems, particularly in extended-reach drilling. |

| Real-Time Monitoring and Adjustments | Uses real-time data from MWD tools and sensors to adjust mud properties on the fly, ensuring optimal performance. | Allows for immediate response to downhole conditions, reducing risks and optimizing drilling efficiency. |

| Environmental Protection and Compliance | Incorporates eco-friendly formulations and waste management practices to minimize environmental impact. | Necessary for meeting environmental regulations, especially in sensitive drilling areas, while maintaining high performance. |

The Latest Advancements in Drilling Mud Systems for Top Drive Drilling Operations

1. High-Performance Mud Formulations

The development of high-performance mud formulations is crucial for top drive drilling operations, which often encounter challenging downhole conditions. These mud systems are designed to provide enhanced rheological properties, superior lubrication, and improved thermal stability.

- Synthetic-Based Mud (SBM): Synthetic-based muds have gained popularity due to their low toxicity, environmental compliance, and superior performance in high-temperature, high-pressure (HTHP) environments. SBMs are engineered to minimize wellbore instability and reduce the risks of differential sticking, which is particularly important in top-drive drilling where the drill string is continuously rotating.

- Nano-Engineered Mud Systems: The incorporation of nanoparticles into drilling mud formulations has led to significant improvements in mud performance. Nanoparticles enhance the carrying capacity of the mud, improve filtration control, and reduce friction between the drill string and wellbore. These benefits are especially valuable in extended reach drilling (ERD) operations commonly associated with top drive systems.

2. Real-Time Monitoring and Adaptive Control

Real-time monitoring and adaptive control of drilling mud systems have become increasingly important in top drive drilling. The ability to monitor mud properties and make adjustments on the fly enhances drilling efficiency and reduces the risk of non-productive time (NPT).

- Automated Mud Mixing Systems: Advanced mud mixing systems are now equipped with automation and control features that allow for real-time adjustments to mud properties. These systems can automatically adjust the mud’s viscosity, density, and other properties based on real-time data, ensuring optimal performance throughout the drilling operation.

- Integrated Measurement-While-Drilling (MWD) Tools: MWD tools integrated with top drive systems provide continuous data on downhole conditions, including pressure, temperature, and mud weight. This data allows for real-time adjustments to the drilling mud, ensuring that it remains within the desired parameters for effective drilling and wellbore stability.

3. Enhanced Lubrication and Friction Reduction

Top drive drilling systems, which allow for continuous rotation of the drill string, place unique demands on drilling mud systems in terms of lubrication and friction reduction.

- Lubricating Additives: Innovative lubricating additives have been developed to reduce torque and drag in top-drive drilling operations. These additives improve the lubricity of the mud, reducing the risk of stuck pipe incidents and extending the life of the drill string. Additives such as graphite, polytetrafluoroethylene (PTFE), and specialty polymers are commonly used to enhance lubrication.

- Biodegradable Lubricants: With increasing environmental regulations, the development of biodegradable lubricants for drilling mud systems has become a priority. These lubricants provide effective friction reduction while minimizing the environmental impact, making them ideal for use in environmentally sensitive areas.

4. Advanced Cuttings Transport and Hole Cleaning

Effective cuttings transport and hole cleaning are critical for maintaining wellbore integrity and preventing issues such as stuck pipe and excessive torque. Innovations in drilling mud systems have focused on improving these aspects to meet the demands of top-drive drilling.

- Viscoelastic Surfactants: Viscoelastic surfactants (VES) are being increasingly used in drilling mud systems to improve cuttings transport and hole cleaning. VES-based muds exhibit unique rheological properties that allow for better suspension of cuttings, particularly in deviated and horizontal wells, which are common in top-drive drilling operations.

- Optimized Flow Dynamics: Advances in fluid dynamics modeling have led to the development of drilling mud systems with optimized flow characteristics. These systems are designed to minimize cutting accumulation and ensure efficient hole cleaning, even in challenging wellbore geometries. The use of computational fluid dynamics (CFD) simulations has been instrumental in fine-tuning these mud systems for top-drive drilling.

5. Environmental Considerations and Sustainability

The oil and gas industry is increasingly focused on sustainability and environmental protection, and drilling mud systems are no exception. Innovations in eco-friendly drilling muds are gaining traction, particularly in regions with stringent environmental regulations.

- Water-Based Mud (WBM) with Green Additives: Water-based muds are being enhanced with environmentally friendly additives that reduce their ecological footprint. These additives include biodegradable polymers, non-toxic corrosion inhibitors, and low-toxicity lubricants. WBMs with green additives provide a viable alternative to oil-based muds (OBM) while maintaining performance in top-drive drilling operations.

- Mud Recycling and Reuse: Technologies for the recycling and reuse of drilling muds are advancing, reducing the environmental impact and operational costs. Closed-loop mud systems allow for the continuous treatment and reuse of drilling fluids, minimizing waste generation and disposal.

How Simulations are Used in Drilling Mud Systems for Top Drive Drilling

Simulations play a crucial role in the design, optimization, and training processes related to drilling mud systems for top-drive drilling.

1. Design and Optimization

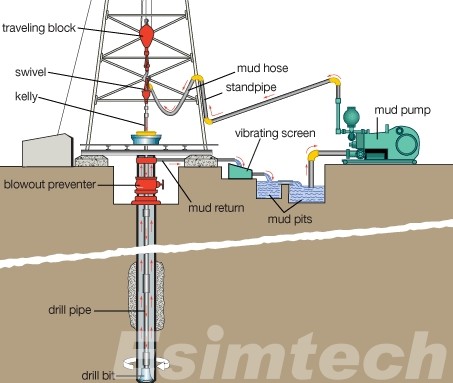

- Modeling Mud Flow Dynamics: Simulations help in modeling the flow of drilling mud through the wellbore, accounting for factors like mud weight, viscosity, and flow rate. These simulations can predict how the mud will behave under different drilling conditions, allowing for the optimization of mud properties to prevent issues like wellbore instability, stuck pipe, or blowouts.

- Predicting Pressure Drops: By simulating the drilling process, engineers can predict pressure drops across the drilling system, which is essential for maintaining the well’s integrity and preventing kicks.

- Erosion and Wear Predictions: Top drive drilling Simulations can predict the erosion and wear of drilling equipment caused by the abrasive nature of drilling mud, enabling better material selection and equipment design.

2. Training and Safety

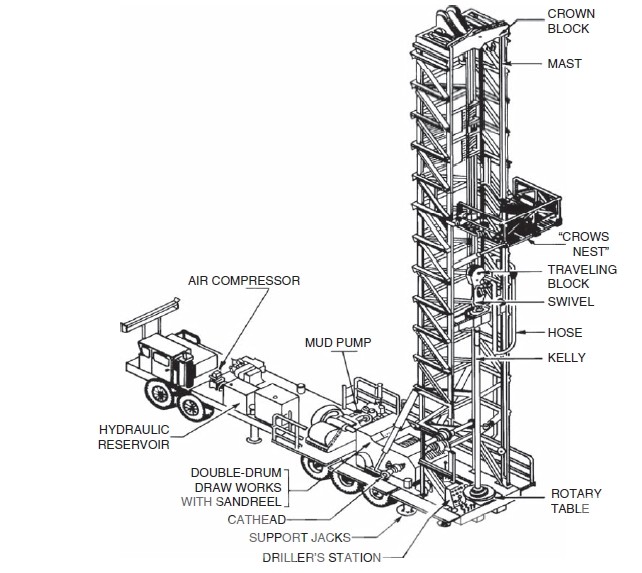

- Operator Training: Simulations provide a risk-free environment for training drilling personnel. Operators can practice managing drilling mud systems in various scenarios, including emergency situations like kick detection and response, without the risk of real-world consequences.

- Virtual Drilling Simulators: These drilling simulators replicate the entire drilling process, including the behavior of drilling mud. Trainees can observe how changes in mud properties or drilling parameters affect the wellbore and learn how to make adjustments in real time.

3. Real-Time Monitoring and Decision Support

- Digital Twins: In advanced drilling operations, simulations can be integrated with real-time data to create a digital twin of the drilling process. This allows for continuous monitoring and adjustment of the drilling mud system, optimizing performance and reducing risks.

- Scenario Analysis: Real-time simulations can be used to run “what-if” scenarios during drilling operations. For instance, if a change in formation pressure is detected, a simulation can quickly predict how different mud weights or flow rates would impact the situation, aiding in rapid decision-making.

4. Research and Development

- Innovative Mud Formulations: Simulations are used in R&D to test new drilling mud formulations before field trials. This reduces the time and cost associated with developing new products by allowing engineers to identify the most promising candidates early in the process.

- Enhanced Top Drive Systems: Simulations contribute to the development of more advanced top drive systems that can handle a wider range of drilling mud properties, improving overall drilling efficiency and safety.

In summary, innovations in drilling mud systems tailored for top drive drilling have significantly enhanced the efficiency, safety, and effectiveness of modern drilling operations, allowing for better control of wellbore stability, improved cuttings transport, and optimized hydraulic performance, all while reducing the environmental impact.