Innovations in Deepwater Oil and Gas Exploration and Production

Deepwater oil and gas exploration and production have been at the forefront of technological advancement in the energy sector. The challenges posed by extreme depths, high pressures, and harsh environments have necessitated the development of innovative solutions. This article explores the current landscape, technological advancements, and future prospects of deepwater oil and gas operations.

Current Landscape of Deepwater Exploration and Production

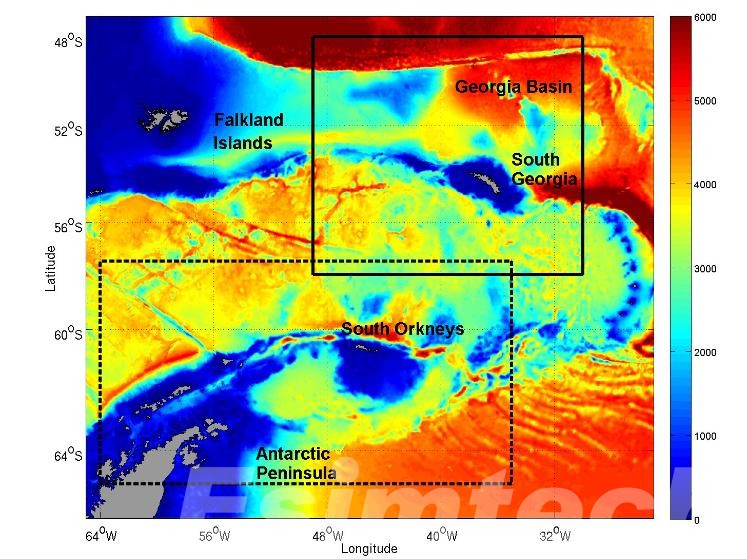

- As energy demand continues to rise, the oil and gas industry is increasingly turning to deeper waters to unlock untapped hydrocarbon resources. Regions like the Gulf of Mexico, Brazil’s pre-salt fields, and offshore West Africa are at the forefront of deepwater operations. These areas are not only rich in hydrocarbons but also technologically demanding, requiring advanced solutions to meet the challenges of extreme water depths, high pressures, and complex geological formations.

- In recent years, the focus has shifted from relatively shallow waters to ultra-deepwater fields, where operations occur at depths of 1,500 meters (4,921 feet) or more.

- As of 2023, deepwater production accounts for nearly 30% of global offshore oil production. Despite the high costs and risks associated with deepwater exploration and production, the potential rewards are equally substantial, with discoveries offering multi-billion-barrel reserves. To keep pace with these opportunities, technological innovation has become a critical driver of progress in the deepwater sector.

Technological Innovations in Deepwater Exploration

Technological advancements have played a crucial role in overcoming the challenges of deepwater exploration. Below are some key innovations that are shaping the future of oil and gas exploration in deepwater environments:

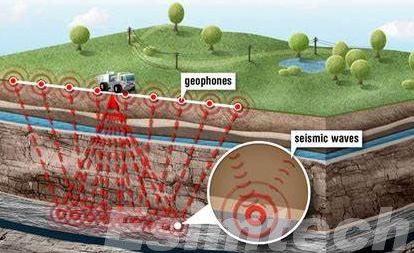

Seismic Imaging

One of the most critical technological innovations in deepwater exploration is seismic imaging. Seismic surveys use sound waves to create detailed images of subsurface structures. In deepwater environments, the high pressures and temperatures can distort seismic signals, making it difficult to obtain accurate images. However, the development of advanced seismic acquisition and processing techniques has overcome these challenges.

- High-Resolution 3D and 4D Seismic: 3D seismic surveys provide a detailed cross-sectional view of the subsurface, while 4D seismic surveys monitor changes in reservoir properties over time. These technologies enable geologists to identify potential hydrocarbon reservoirs with greater precision.

- Wide-Azimuth Seismic: Wide-azimuth seismic surveys acquire data from a wider range of angles, providing more accurate subsurface imaging, especially in complex geological settings.

Data Analytics and Machine Learning

The vast amounts of data generated from deepwater exploration require sophisticated data analysis tools. Machine learning algorithms can analyze seismic data to identify patterns and anomalies that may indicate the presence of hydrocarbons. Additionally, machine learning can be used to optimize exploration workflows and reduce costs.

- Pattern Recognition: Machine learning algorithms can identify patterns in seismic data that are indicative of hydrocarbon reservoirs, such as bright spots and amplitude anomalies.

- Anomaly Detection: Machine learning can also be used to detect anomalies in seismic data that may indicate geological faults or other subsurface features that could impact hydrocarbon exploration.

- Workflow Optimization: Machine learning can be used to optimize exploration workflows by automating tasks such as data processing, interpretation, and well planning.

Autonomous Underwater Vehicles (AUVs)

AUVs are unmanned submersibles that can be deployed to explore deepwater regions without human intervention. These vehicles are equipped with sensors to collect data on water depth, temperature, salinity, and other environmental parameters. AUVs can also be used to inspect underwater structures and identify potential hazards.

- Swarms of AUVs: Multiple AUVs can be deployed together to cover a larger area more efficiently. This approach can be particularly useful for large-scale surveys and environmental monitoring.

- Hybrid AUVs: Hybrid AUVs combine the capabilities of AUVs and remotely operated vehicles (ROVs), allowing them to perform a wider range of tasks.

Remotely Operated Vehicles (ROVs)

ROVs are similar to AUVs but are controlled by operators on the surface. ROVs can be equipped with various tools, such as cameras, drills, and manipulators, to perform tasks such as drilling, sampling, and maintenance. ROVs are essential for supporting deepwater production operations.

- Advanced ROV Technology: Recent advancements in ROV technology include the development of more powerful manipulators, higher-resolution cameras, and improved navigation systems. These improvements have made ROVs more versatile and capable of performing a wider range of tasks.

- Tethered and Untethered ROVs: Tethered ROVs are connected to a surface vessel by a cable that provides power and communication. Untethered ROVs are equipped with batteries and wireless communication systems, allowing them to operate independently for longer periods of time.

Oceanographic Modeling

Oceanographic modeling involves simulating the behavior of ocean currents, waves, and other environmental factors. This information is crucial for understanding the impact of deepwater exploration and production activities on the marine environment. Oceanographic models can also be used to predict the movement of oil spills and develop effective response strategies.

- Environmental Impact Assessment: Oceanographic models can be used to assess the potential environmental impacts of deepwater exploration and production activities, such as the risk of oil spills or habitat destruction.

- Spill Response Planning: Oceanographic models can be used to predict the movement of oil spills and develop effective response strategies, such as deploying containment booms or dispersants.

- Climate Change Impacts: Oceanographic models can be used to study the impacts of climate change on deepwater environments, such as changes in sea level, ocean temperature, and currents.

Technological Innovations in Deepwater Drilling in Oil and Gas

Once a potential reservoir has been identified, the next challenge is safely and efficiently drilling into it, often through thousands of feet of water and rock. The harsh environment of deepwater operations, characterized by high pressures and temperatures, demands cutting-edge drilling technologies.

1. Dynamic Positioning Systems (DPS)

Maintaining precise positioning of drilling rigs in deepwater is essential, especially given the strong currents and harsh conditions typical of these environments. Dynamic positioning systems, equipped with multiple thrusters and GPS-based controls, enable floating rigs to maintain their exact location without the need for anchoring. This not only improves drilling accuracy but also reduces the risk of accidents and environmental damage.

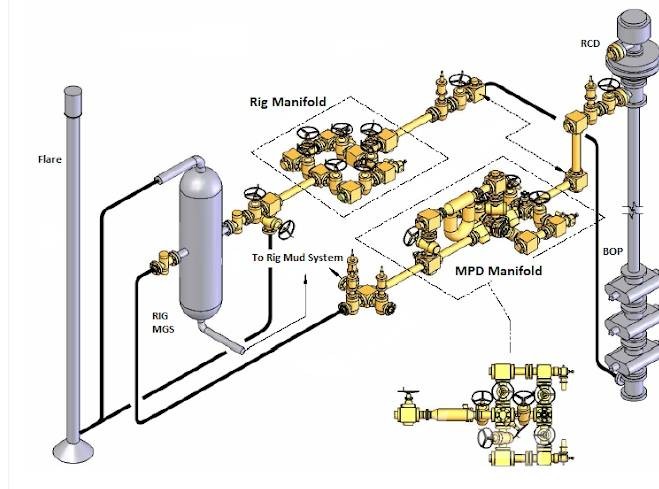

One of the significant challenges of deepwater drilling is managing the pressure exerted by fluids in the reservoir. Traditional drilling methods often struggle with high-pressure zones, leading to blowouts or wellbore instability. Managed Pressure Drilling (MPD) systems offer real-time control over wellbore pressures, allowing operators to safely and efficiently drill through challenging formations. MPD can also help reduce non-productive time, leading to significant cost savings.

3. Subsea Drilling Systems

Subsea drilling systems are increasingly being used in deepwater fields, where surface conditions make traditional drilling methods inefficient or unsafe. These systems are installed directly on the seafloor, closer to the reservoir, and are operated remotely from the surface. By drilling from the seabed, operators can minimize the environmental footprint of their operations while also improving drilling accuracy and reducing the risk of equipment failure.

Innovations of Deepwater Oil and Gas Production Technologies

Producing oil and gas from deepwater fields presents numerous technical challenges due to the harsh conditions found at extreme depths, such as high pressure, low temperatures, and complex flow dynamics. To address these issues and enhance efficiency, safety, and reliability, the industry has introduced several cutting-edge production technologies.

| Technology | Description | Benefits |

| Subsea Production Systems | A network of equipment installed on the seabed to collect, process, and transport hydrocarbons to surface facilities. | Improved efficiency, reduced transportation costs, and increased reliability. |

| Floating Production Storage and Offloading (FPSO) Vessels | Floating platforms equipped with facilities for production, storage, and offloading of oil and gas. | Flexibility, mobility, and the ability to operate in remote locations. |

| Subsea Separation and Boosting Technologies | Equipment that separates oil, gas, and water at the seabed and increases the pressure of the produced fluids. | Improved hydrocarbon recovery, reduced pipeline risks, and increased transportation efficiency. |

| Underwater Robotics | Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) used for inspection, maintenance, and repair of subsea equipment. | Increased safety, improved efficiency, and reduced downtime. |

| Data Analytics and Digitalization | Advanced data analytics tools and digital twins used to monitor production performance, detect anomalies, and optimize processes. | Enhanced decision-making, improved operational efficiency, and reduced costs. |

| Environmental Technologies | Leak detection systems, spill response technologies, and emissions reduction measures. | Minimized environmental impact and improved public perception. |

What’s the Future?

The future of deepwater exploration lies in automation, sustainability, and digitalization. Technologies like carbon capture, robotics, and AI will improve safety, reduce costs, and lower emissions. Renewable energy integration, such as wind and solar, will help make operations more eco-friendly. These innovations will drive the industry’s evolution, making deepwater oil and gas production more efficient, safer, and aligned with global environmental goals.