How to Optimize Costs and Efficiency in Well Completion

Well completion is a critical process in oil and gas production, directly impacting operational performance and overall project economics. Effective well completion not only ensures maximum resource recovery but also reduces costs and enhances operational efficiency. With advancements in technology and innovative practices, operators can achieve significant improvements in cost-effectiveness without compromising operational integrity.

Key Factors Influencing Costs and Efficiency in Well Completion

This chart illustrates the various factors that play a significant role in determining the costs and efficiency of well completion operations. Managing these elements effectively is crucial for optimizing both short-term costs and long-term performance.

| Factor | Description | Impact on Costs and Efficiency |

| Reservoir Characteristics | Porosity, permeability, and heterogeneity of the reservoir. | Directly affects well design, required interventions, and operational complexity. |

| Completion Design | Type of completion (e.g., open hole, cased and perforated, intelligent completions). | Determines tool selection, material costs, and operational procedures, influencing costs. |

| Hydraulic Fracturing | Use of fracturing techniques to enhance production. | Fracturing intensity, fluid types, and pump efficiency significantly affect costs. |

| Technology Adoption | Deployment of advanced technologies (e.g., digital twins, intelligent completions). | Increases upfront costs but improves operational efficiency, reducing long-term expenses. |

| Downhole Equipment | Tools used in the completion (e.g., packers, plugs, valves). | Higher-quality tools ensure reliability and longer service life, reducing failure risks. |

| Well Depth and Location | Depth of the well and geographic location (onshore vs offshore). | Deeper and offshore wells increase drilling and completion costs due to complexity. |

| Operational Time (NPT) | Non-productive time due to delays or inefficiencies. | Extended completion times lead to higher labor and equipment costs. |

| Logistics and Transportation | Costs associated with moving equipment and materials to the site. | Remote locations or offshore environments increase transportation costs. |

| Cementing and Perforation | Cementing quality and perforation techniques used during completion. | Poor cementing or inefficient perforation leads to rework, increasing costs and downtime. |

| Regulatory Compliance | Adherence to environmental and safety regulations. | Compliance requirements (e.g., emission reductions, waste management) increase costs. |

| Workforce and Expertise | Skill level and experience of personnel involved in completion operations. | Highly skilled workforce ensures efficient operation, reducing downtime and errors. |

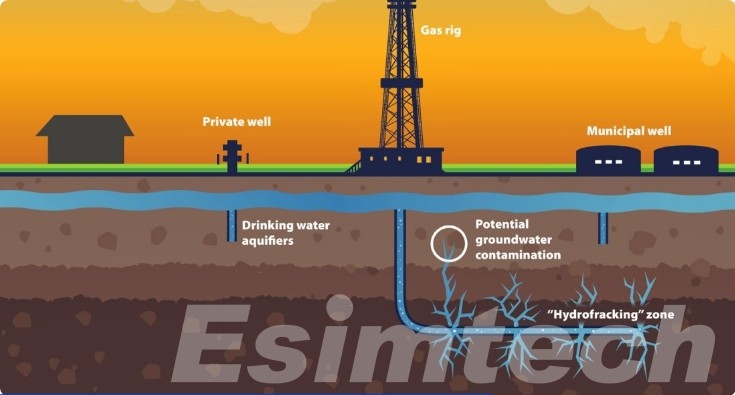

| Water Usage and Disposal | Amount of water used in processes like fracturing and how wastewater is managed. | Increased water requirements and disposal add to operational and environmental costs. |

| Maintenance and Downtime | Frequency of equipment breakdowns or maintenance requirements. | High maintenance costs and downtime can reduce operational efficiency and increase expenses. |

| Real-Time Data and Monitoring | Availability of real-time monitoring tools for decision-making. | Enables more precise control and timely interventions, reducing costly mistakes or delays. |

| Economic Conditions | Fluctuating oil and gas prices and economic factors affecting supply and demand. | Low prices pressure cost-cutting measures, but high prices justify higher capital spending. |

Strategies to Optimize Costs and Efficiency in Well Completion

1. Data-Driven Decision Making

Advanced data analytics and real-time monitoring technologies enable operators to make informed decisions during the well completion process. By analyzing subsurface data and well performance metrics, operators can optimize perforation strategies to target productive zones, predicting and address potential risks, such as sand production or pressure anomalies and minimizing material waste and unnecessary operational steps.

2. Implement Modular Completion Systems

Modular systems adopts pre-engineered, standardized components that can be easily assembled and customized. These systems streamline installation, reduce downtime, and enable faster project execution. Their flexibility allows for scalability and easy integration with existing infrastructure, lowering maintenance and operational costs. By simplifying processes and enhancing reliability, modular completion systems provide a cost-effective and efficient solution for modern well completion projects.

3. Use High-Performance Materials

Using high-performance materials in well completion enhances durability, reliability, and resistance to extreme conditions, such as high pressures, temperatures, and corrosive environments. These materials, including advanced alloys and composites, reduce equipment failures, extend service life, and minimize maintenance costs. By improving the performance of critical components, they enable efficient resource utilization, decrease downtime, and optimize overall operational costs, making them a vital component of modern, cost-effective well completion strategies.

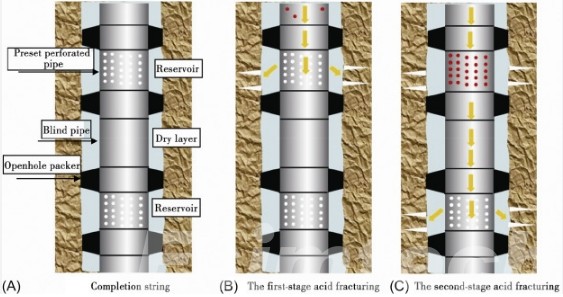

4. Optimize Hydraulic Fracturing

Hydraulic fracturing is a key component of well completion, and the optimization of hydraulic fracturing can significantly reduce costs. Optimizing hydraulic fracturing can be realized through using advanced software to calculate the optimal volume and type of fracturing fluid, ensuring only productive zones are fractured, minimizing wastage and employing recycled water to reduce environmental costs and water sourcing expenses.

5. Standardize Processes and Equipment

Standardizing processes and equipment in well completion ensures consistency, reduces operational complexity, and minimizes errors. By using uniform procedures and compatible equipment, companies can streamline workflows, lower training requirements, and improve efficiency. Standardization also simplifies procurement and maintenance, leading to cost savings and faster project execution. This approach enhances reliability, scalability, and overall performance, making it a key strategy for optimizing costs and efficiency in well completion projects.

6. Collaborate with Experienced Service Providers

Partnering with trusted service providers helps operators gain access to the latest technologies and expertise. With the Collaboration, tailored solutions can be implemented for unique reservoir challenges, as well as reduced downtime due to specialized support and cost-sharing for high-capital projects.

7. Emphasize Risk Management

Emphasizing risk management involves identifying, assessing, and mitigating potential hazards to ensure safe and efficient operations. Proactive strategies, such as real-time monitoring, predictive analytics, and contingency planning, help prevent costly delays, equipment failures, and safety incidents. By minimizing risks, companies can reduce downtime, optimize resource allocation, and enhance overall project efficiency. A strong focus on risk management leads to more reliable outcomes and significant cost savings in well completion processes.

Innovative Technologies in Optimizing Costs and Efficiency for Well Completion

1. Digital Twins

Digital twins are virtual replicas of physical assets, processes, or systems that are revolutionizing well completion by enhancing cost efficiency and operational performance. By simulating real-time conditions and scenarios, digital twins enable predictive analytics, proactive maintenance, and process optimization. They allow operators to test and refine strategies, identify inefficiencies, and prevent potential failures, reducing downtime and expenses. With improved decision-making and resource management, digital twins offer a powerful solution for streamlining well completion while ensuring safety and maximizing efficiency.

2. Intelligent Completion Systems

Equipped with sensors and remotely operated controls, intelligent well completion systems enhance operational efficiency by providing real-time data on flow rates, pressure, and temperature, enabling zonal control for optimized hydrocarbon production and reducing the need for costly interventions by automating adjustments.

3. Enhanced Perforation Systems

Enhanced perforation systems are advanced technologies designed to maximize well productivity while optimizing costs and efficiency during well completion. These systems use precise, high-energy perforating techniques to create optimal flow paths, ensuring better reservoir connectivity and hydrocarbon recovery. By improving perforation accuracy and minimizing formation damage, they reduce the need for costly interventions and enhance operational efficiency. Additionally, enhanced perforation systems contribute to faster project timelines and improved resource utilization, making them a critical innovation in modern well completion strategies.

4. Automation and Robotics

Automation is streamlining repetitive and high-risk tasks in well completion. Examples include automated cementing units for precise cement placement, robotic pipe handling systems that reduce manual labor and enhance safety and automated wellbore cleaning tools to ensure debris-free environments for efficient completion.

5. Predictive Maintenance with AI and Machine Learning

Predictive maintenance with AI and machine learning is revolutionizing well completion processes by enhancing cost efficiency and operational reliability. These advanced technologies analyze real-time data from sensors and equipment to predict potential failures and optimize maintenance schedules. By identifying issues before they escalate, predictive maintenance reduces downtime, extends equipment lifespan, and minimizes unnecessary expenses. In well completion, this approach improves safety, enhances resource utilization, and ensures seamless operations, making it a vital strategy for modern oil and gas industries.

6. Eco-Friendly Technologies

Eco-friendly technologies for well completion focus on reducing environmental impact while optimizing costs and operational efficiency. These innovations include the use of biodegradable drilling fluids, low-emission equipment, water recycling systems, and renewable energy sources. By integrating sustainable practices, companies can lower resource consumption, reduce waste, and comply with environmental regulations. These technologies not only enhance operational efficiency but also contribute to cost savings and a greener footprint, making them a vital component of responsible and modern well completion strategies.

7. Cloud-Based Data Platforms

Cloud-based data platforms are enabling real-time data integration, analysis, and collaboration in well completion. These platforms centralize data from various sources, allowing for seamless monitoring, predictive analytics, and decision-making. By leveraging cloud technology, companies can reduce IT infrastructure costs, enhance operational efficiency, and improve resource allocation. Cloud-based platforms also facilitate remote access and collaboration, empowering teams to address challenges promptly. This approach streamlines workflows, reduces downtime, and optimizes costs, making it an essential tool for modern well completion processes.

Summary

Optimizing costs and efficiency in well completion requires a comprehensive approach that combines advanced technology, strategic planning, and collaboration. Through adopting data-driven tools, advanced materials, and innovative completion designs, operators can achieve significant cost savings while maximizing well performance. The integration of these strategies not only ensures economic benefits but also enhances the long-term viability of oil and gas operations in an increasingly competitive industry.