How to Mitigate the Effects of Torque and Drag in Drilling Performance

Drilling for oil and gas is a complex and demanding process that requires precise control and management of various forces acting on the drilling assembly. Among these forces, torque and drag play a significant role in determining the efficiency and success of drilling operations. In this article, we delve into the fundamentals of torque and drag in drilling, their impact on drilling performance, and strategies for mitigating their effects to optimize drilling operations.

Understanding the Role of Torque and Drag in Drilling

Torque

Powering the Rotation Torque, in drilling, refers to the rotational force applied to the drill string to turn the drill bit and penetrate the subsurface formations. It originates at the surface from the rotary table or top drive system and is transmitted downhole through the drill string. The magnitude of torque is determined by factors such as the weight on bit, drill string configuration, and drilling parameters. It is essential for achieving the required rate of penetration and maintaining drilling efficiency.

Drag

Resisting the Progress Drag, on the other hand, is the resistance encountered by the drill string as it moves through the wellbore. It is caused by various factors, including friction between the drill string and the wellbore wall, wellbore geometry, and formation properties. Drag can impede the progress of the drill string, reducing penetration rates, increasing wear and tear on drilling equipment, and posing challenges to wellbore stability.

The Interplay Between Torque and Drag

Torque and drag are interrelated phenomena that often work in tandem during drilling operations. As torque is applied to the drill string to rotate the bit, it generates reactive forces that contribute to drag. Conversely, drag can increase the torque required to rotate the drill string, leading to higher energy consumption and potential equipment failures. This complex interplay between torque and drag requires careful management and optimization to ensure drilling efficiency and safety.

Challenges and Implications of Torque and Drag in Drilling

1. Reduced Penetration Rates

Excessive torque and drag can hinder the ability of the drill bit to advance through the formation efficiently. This leads to reduced penetration rates, prolonging the drilling process and increasing overall operational costs.

2. Increased Wear and Tear

High levels of torque and drag can accelerate wear and tear on drilling equipment, including the drill string, drill bit, and downhole tools. This results in higher maintenance costs and increased downtime for repairs and replacements.

3. Stuck Pipe Incidents

Excessive drag can cause the drill string to become stuck or lodged in the wellbore, leading to costly stuck pipe incidents. Retrieving the stuck equipment requires specialized techniques and can result in delays and additional expenses.

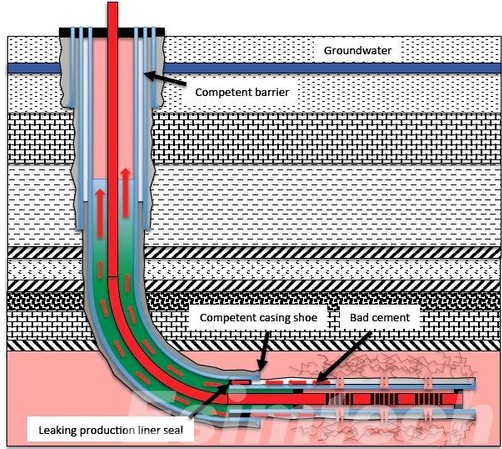

4. Wellbore Instability

Torque and drag contribute to wellbore instability issues such as differential sticking, hole deviation, and formation damage. These issues can compromise the integrity of the wellbore and pose safety risks to drilling personnel and equipment.

5. Increased Energy Consumption

High levels of torque and drag require greater energy consumption to overcome resistance and maintain drilling operations. This results in increased fuel usage and operational costs, affecting the overall economics of drilling projects.

6. Operational Delays

Dealing with torque and drag-related issues can lead to operational delays and downtime, impacting project timelines and delivery schedules. Delays in drilling operations can have significant financial implications for operators and stakeholders.

7. Impact on Drilling Performance

Torque and drag directly affect drilling performance, influencing key metrics such as rate of penetration, footage drilled per day, and overall efficiency. Poor drilling performance can undermine the success of drilling projects and jeopardize investment returns.

Key Factors Influencing Torque and Drag in Drilling

1. Wellbore Geometry and Inclination

The geometry and inclination of the wellbore play a significant role in determining torque and drag. Deviations from vertical wellbores or changes in wellbore diameter can increase frictional forces and drag, affecting the overall efficiency of drilling operations.

2. Formation Properties

Variations in formation characteristics such as rock type, hardness, porosity, and fluid content can influence torque and drag. Harder formations may require higher torque to penetrate, while softer formations may result in higher drag due to increased friction.

3. Drill String Design and Configuration

The design and configuration of the drill string, including the type of drill pipe, drill collars, and bottom hole assembly (BHA), can impact torque and drag. Factors such as drill bit size, weight on bit, and drill string stiffness affect the overall performance and response to torque and drag forces.

4. Drilling Fluid Properties

The properties of the drilling fluid, including viscosity, density, and lubricity, play a crucial role in mitigating torque and drag. Proper selection and management of drilling fluids can help reduce frictional forces and improve the efficiency of drilling operations.

5. Operational Parameters

Various operational parameters such as rotary speed, weight on bit, drilling direction, and drilling fluid flow rate influence torque and drag. Adjusting these parameters based on downhole conditions and formation characteristics can help optimize drilling performance and minimize torque and drag effects.

6. Wellbore Trajectory

The trajectory of the wellbore, including the build rate, turn rate, and dogleg severity, affects torque and drag. Deviations from planned well trajectories can increase frictional forces and drag, leading to operational challenges and reduced drilling efficiency.

7. Downhole Conditions

Downhole conditions such as wellbore temperature, pressure, and fluid flow dynamics can impact torque and drag. Changes in downhole conditions, such as drilling through different formations or encountering downhole obstructions, can affect torque and drag responses.

8. Drilling Equipment and Tooling

The condition and performance of drilling equipment and tooling, including the drill bit, drilling motors, and downhole tools, influence torque and drag. Proper maintenance and selection of equipment can help minimize frictional losses and optimize drilling efficiency.

Effective Mitigation Strategies of Torque and Drag in Drilling

To mitigate the effects of these forces and optimize drilling performance, various strategies and technologies can be employed.

1. Wellbore Trajectory Optimization

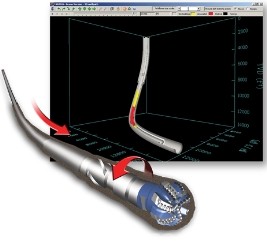

Planning and designing well trajectories to minimize tortuosity and reduce frictional forces can help mitigate torque and drag. Techniques such as rotary steerable systems (RSS) and advanced surveying tools enable precise wellbore positioning, minimizing drag and improving drilling efficiency.

Simulation technology facilitates detailed analysis of torque and drag effects throughout the drilling process. Engineers can input parameters such as weight on bit, rotary speed, drilling fluid properties, and wellbore geometry into the simulation software to calculate torque and drag values along the entire wellbore trajectory. It enables engineers to optimize wellbore trajectories to minimize torque and drag. By simulating different wellbore paths and assessing their impact on torque and drag behavior, engineers can identify the most favorable trajectory that reduces frictional losses and improves drilling efficiency. This optimization process helps enhance hole quality, minimize drilling time, and reduce operational costs.

2. Drilling Fluid Management

Proper selection and management of drilling fluids with optimal lubricating properties and rheological characteristics are essential for mitigating torque and drag. High-performance drilling fluids, such as synthetic-based muds (SBM) or oil-based muds (OBM), reduce frictional losses and improve hole cleaning, enhancing drilling efficiency.

Simulation software allows engineers to simulate the performance of different drilling fluids and assess their impact on torque and drag. By inputting drilling fluid properties such as viscosity, density, and lubricity into the simulation model, engineers can evaluate how different fluid formulations affect frictional losses and drag behavior. This analysis helps optimize drilling fluid selection and formulation to minimize torque and drag and improve drilling efficiency.

3. Drill String Design Optimization

Optimizing drill string design and configuration can help minimize torsional resistance and reduce drag. Using lighter and more flexible drill pipe materials, optimizing weight on bit (WOB), and selecting appropriate bottom hole assembly (BHA) components improve weight transfer to the bit and enhance drilling performance.

4. Advanced Drilling Technologies

Deployment of advanced drilling technologies such as rotary steerable systems (RSS), drilling motors, and downhole drilling optimization tools can mitigate torque and drag effects. RSS systems provide precise wellbore steering, reducing doglegs and minimizing frictional losses, while drilling motors deliver high torque and rotational speed, improving drilling efficiency in challenging formations.

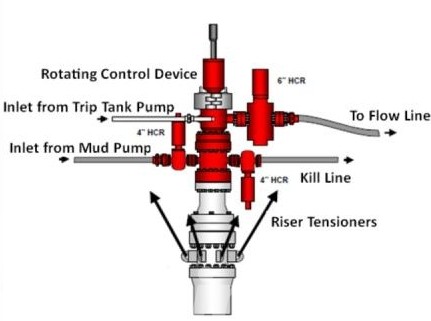

5. Real-time Monitoring and Control

Utilizing real-time monitoring and control systems to assess torque and drag conditions and adjust drilling parameters accordingly is critical for optimizing drilling performance. Continuous monitoring of downhole conditions, drilling parameters, and torque/drag trends enables proactive decision-making and adjustments to minimize operational risks and maximize drilling efficiency.

Simulation technology can be integrated with real-time data acquisition systems to provide continuous monitoring and control of torque and drag during drilling operations. By comparing real-time data with simulation predictions, engineers can identify deviations and take proactive measures to adjust drilling parameters and mitigate potential issues. This real-time drilling simulators help optimize drilling performance, enhance safety, and minimize operational risks.

6. Wellbore Stability Management

Managing wellbore stability issues such as differential sticking and hole enlargement is essential for mitigating torque and drag. Techniques such as wellbore strengthening, casing while drilling (CWD), and managed pressure drilling (MPD) help stabilize the wellbore, reducing frictional losses, and improving drilling efficiency in challenging formations.

7. Continuous Training and Education

Providing comprehensive training and education programs for drilling personnel on torque and drag management techniques and best practices is essential. Equipping personnel with the knowledge and skills to identify, analyze, and mitigate torque and drag issues enhances operational efficiency, safety, and performance.

Conclusion

Torque and drag pose significant challenges in drilling operations, impacting efficiency, safety, and economics. By understanding the underlying mechanisms and employing effective mitigation strategies, drillers can minimize the impact of torque and drag in drilling, optimize drilling performance, and maximize the success of their projects.