How to Improve Drilling Efficiency in Top Drive Drilling

Top drive drilling systems have revolutionized the oil and gas industry by enhancing the efficiency and safety of drilling operations. As the demand for energy continues to rise, optimizing drilling efficiency of top drive drilling is crucial.

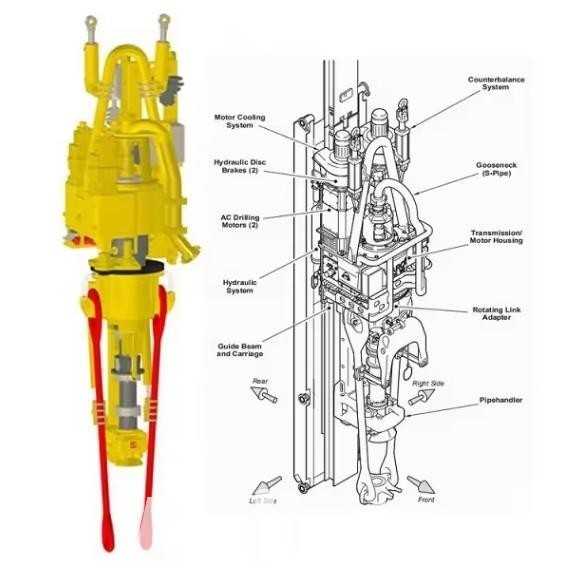

Understanding Top Drive Drilling

Top drive drilling replaces the traditional Kelly system with a top drive, which is a motor that is suspended from the derrick and can move up and down the derrick while rotating the drill string. Here’s a chart that summarizes the key aspects of understanding the top drive system.

| Category | Description |

| Components | Top Drive Unit: The primary motor that rotates the drill string. Elevator: Mechanism to lift and lower the drill string. Swivel: Allows the drill string to rotate freely. Torque Wrench: Used to make up or break out drill pipe connections. Control System: Manages the operation of the top drive, typically computerized. |

| Advantages | Increased Safety: Reduces manual handling of drill pipes, lowering the risk of accidents. Improved Efficiency: Continuous rotation during drilling reduces non-productive time. Enhanced Precision: Allows for more precise control of the drill string, improving drilling accuracy. Reduced Drilling Time: Faster connections and disconnections of drill pipes. |

| Operational Steps | Installation: The top drive is installed in the derrick or mast of the drilling rig. Connection: The top drive is connected to the drill string and the control system is engaged. Drilling: The top drive rotates the drill string, advancing the bit into the formation. Pipe Handling: The elevator is used to add or remove sections of the drill pipe as drilling progresses. 5. Monitoring: Continuous monitoring and adjustments are made via the control system to optimize drilling performance. |

Strategies to Improve Drilling Efficiency in Top Drive Drilling

1. Utilize Advanced Automation Technologies

Automation plays a significant role in enhancing drilling efficiency. By integrating advanced automation technologies, such as programmable logic controllers (PLCs) and real-time data analytics, operators can monitor and control drilling parameters more precisely. Automation reduces human error, increases operational consistency, and allows for real-time adjustments to drilling processes, leading to improved efficiency and reduced downtime.

2. Implement Predictive Maintenance

Predictive maintenance uses data analytics to predict equipment failures before they occur. By monitoring the condition of the top drive system and associated components, operators can schedule maintenance activities proactively, reducing unexpected breakdowns. This approach not only extends the lifespan of the equipment but also minimizes downtime, ensuring continuous and efficient drilling operations.

3. Optimize Drilling Parameters

Careful optimization of drilling parameters such as weight on bit (WOB), rotary speed, and mud flow rate is essential. Using real-time data, operators can adjust these parameters to match the specific conditions of the wellbore, maximizing drilling speed and efficiency. Advanced software tools can analyze data and provide recommendations for optimal parameter settings, improving overall performance.

4. Enhance Drill String Design

The design of the drill string, including the selection of drill bits, collars, and stabilizers, significantly impacts drilling efficiency. Using high-quality, durable materials and innovative designs can reduce wear and tear, enhance drilling speed, and improve directional control. Regularly reviewing and updating drill string design based on the latest technological advancements can lead to substantial efficiency gains.

5. Train and Develop Skilled Operators

Well-trained operators are crucial for the efficient operation of top drive drilling systems. Regular training programs that focus on the latest technologies, best practices, and safety protocols ensure that operators are well-prepared to handle various drilling scenarios. Continuous professional development and skill enhancement can lead to more efficient and safer drilling operations.

6. Integrate Real-Time Monitoring and Analytics

Real-time monitoring systems provide continuous data on drilling conditions, equipment performance and operational parameters. By integrating these systems with advanced analytics platforms, operators can gain valuable insights into drilling efficiency. Identifying trends, detecting anomalies, and making data-driven decisions can significantly enhance operational performance and efficiency.

7. Improve Drilling Fluid Management

Efficient management of drilling fluids is essential for maintaining wellbore stability and optimizing drilling performance. Proper selection and maintenance of drilling fluids can reduce friction, cool the drill bit, and remove cuttings effectively. Implementing advanced fluid monitoring and management systems can ensure optimal fluid properties, leading to improved drilling efficiency.

8. Adopt Enhanced Safety Protocols

Safety is paramount in drilling operations. Enhanced safety protocols not only protect personnel but also prevent equipment damage and operational delays. Regular safety audits, emergency response drills, and the adoption of safety management systems can minimize risks and ensure smooth, uninterrupted drilling operations.

9. Leverage Collaborative Technologies

Collaboration between on-site personnel and remote experts can improve decision-making and problem-solving. Using collaborative technologies, such as video conferencing and shared data platforms, allows for real-time consultation and support, enhancing operational efficiency and reducing downtime.

10. Continuously Review and Improve Processes

Continuous improvement is key to maintaining high drilling efficiency. Regularly reviewing operational processes, identifying areas for improvement, and implementing best practices can lead to incremental gains in efficiency. Encouraging a culture of innovation and continuous learning within the organization ensures that drilling operations remain at the forefront of technological advancements.

How Top Drive Drilling Simulation is Contributing to Improving Drilling Efficiency

Top drive drilling simulation provides a controlled, virtual environment to train personnel, test equipment, and refine drilling techniques.

1. Enhanced Training and Skill Development

Top drive drilling simulation system offers a realistic and immersive training experience for drilling personnel. By simulating various drilling scenarios, operators can practice handling different situations, from routine operations to emergency responses. This hands-on experience helps operators develop and refine their skills, ensuring they are well-prepared to manage real-world challenges efficiently. As a result, the likelihood of errors and operational downtime decreases, directly improving drilling efficiency.

2. Risk-Free Environment for Experimentation

Simulations provide a risk-free environment where new drilling techniques and equipment can be tested without the consequences of real-world failures. This capability allows for experimentation with different drilling parameters, equipment configurations, and operational strategies. By identifying the most effective approaches through simulation, operators can implement best practices in actual drilling operations, leading to optimized performance and increased efficiency.

3. Optimization of Drilling Parameters

Drilling simulations enable operators to experiment with and optimize various drilling parameters, such as weight on bit (WOB), rotary speed, and mud flow rate, in a controlled setting. By analyzing the outcomes of different parameter combinations, operators can determine the optimal settings for specific well conditions. Applying these optimized parameters in real drilling operations enhances drilling speed, reduces wear and tear on equipment, and improves overall efficiency.

4. Equipment Testing and Validation

Before deploying new top drive systems or components in the field, simulations can be used to test and validate their performance. This pre-deployment testing helps identify potential issues and ensures that equipment functions as expected under various conditions. By addressing any problems before they arise in real-world operations, operators can prevent equipment failures and minimize downtime, contributing to more efficient drilling processes.

5. Real-Time Data Analysis and Feedback

Advanced drilling simulations incorporate real-time data analysis, allowing operators to receive immediate feedback on their performance. This instant feedback loop helps operators understand the impact of their actions and make necessary adjustments quickly. The ability to analyze data in real time also aids in identifying trends and patterns that can inform better decision-making and operational strategies, leading to enhanced drilling efficiency.

6. Improved Safety and Reduced Operational Risks

Safety is a paramount concern in drilling operations. Simulations allow operators to practice and perfect their responses to emergency scenarios, such as equipment failures, blowouts, or sudden changes in well conditions, without the associated risks. By improving safety protocols and preparedness through simulation training, the frequency and severity of accidents can be reduced. Fewer accidents mean less downtime and more efficient drilling operations.

7. Cost-Effective Training Solution

Traditional training methods often require significant time and resources, including the use of expensive equipment and materials. Simulations offer a cost-effective alternative by providing comprehensive training experiences without the need for physical resources. This cost efficiency enables more frequent and thorough training sessions, ensuring that personnel are always up-to-date with the latest techniques and best practices, further enhancing drilling efficiency.

8. Facilitation of Remote Collaboration

Modern drilling simulations often include features that facilitate remote collaboration. Engineers, geologists, and other experts can participate in simulation sessions from different locations, providing their insights and recommendations in real time. This collaborative approach ensures that all relevant expertise is utilized in developing and refining drilling strategies, leading to more informed decisions and improved operational efficiency.

Why Choose Top Drive Drilling Simulator from Esimtech

With many years of experience in developing petroleum engineering simulation systems for the oil and gas industry, Esimtech has produced a series of proprietary products in petroleum engineering and equipment simulation systems.

Choosing the top drive drilling simulator from Esimtech ensures unparalleled training and operational efficiency in drilling operations. Esimtech simulators provide realistic, immersive training experiences that replicate a wide range of drilling scenarios. This advanced technology allows operators to hone their skills, optimize drilling parameters, and practice emergency responses in a safe, controlled environment. With comprehensive features, real-time data analysis, and remote collaboration capabilities, the Top drive simulation system provided by Esimtech, enhances safety, reduces operational risks, and improves overall drilling performance. Trust Esimtech for cutting-edge solutions that prepare your team for the complexities of modern drilling.