How to Exploit Fractured Reservoirs Effectively

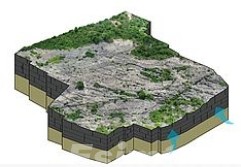

Fractured reservoirs are a critical type of geological formation within the oil and gas industry, characterized by the presence of natural or induced fractures within the rock. These fractures significantly impact the reservoir’s ability to store and transmit fluids, making them both an opportunity and a challenge for hydrocarbon production.

What Are Fractured Reservoirs

Fractured reservoirs are subsurface geological formations where the primary porosity is enhanced or even dominated by fractures rather than the rock matrix itself. These fractures can be natural, resulting from tectonic forces, or induced through human activities such as hydraulic fracturing. The fractures serve as pathways for fluids, enabling oil, gas, and water to move through the reservoir more easily compared to conventional reservoirs.

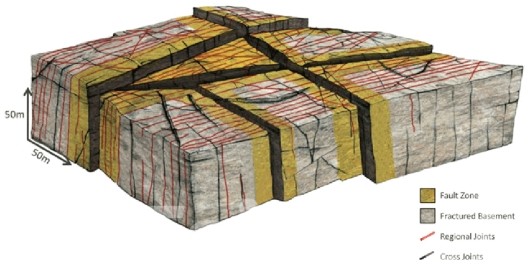

Fractured reservoirs are often found in carbonate rocks like limestone and dolomite, as well as in tight sandstones and shales. The fractures can vary in size, from microscopic cracks to large faults, and their orientation, density, and connectivity are critical factors that influence the reservoir’s behavior and productivity.

Types of Fractures

- Natural Fractures: These occur due to geological processes like tectonic stress, folding, or faulting. They can vary widely in size, orientation, and connectivity, all of which influence the reservoir’s behavior.

- Induced Fractures: Created through human activities such as drilling or hydraulic fracturing (fracking), these fractures are often engineered to enhance reservoir permeability and improve hydrocarbon recovery.

Significance of Fractured Reservoirs

- Enhanced Fluid Flow: The presence of fractures enhances the permeability of the reservoir, allowing fluids to flow more readily through the rock. This can lead to higher production rates compared to conventional reservoirs with similar porosity but lower permeability.

- Resource Potential: Fractured reservoirs often contain significant hydrocarbon reserves that would otherwise be difficult to extract. Their contribution to global oil and gas supply is substantial, particularly in regions where conventional reservoirs are becoming depleted.

- Economic Viability: In many cases, the economic viability of oil and gas projects hinges on the ability to efficiently produce from fractured reservoirs. Advanced techniques and technologies have made it possible to tap into these challenging reservoirs, turning them into profitable ventures.

Challenges in Developing Fractured Reservoirs

This chart highlights the main challenges faced in the development of fractured reservoirs, emphasizing the complexity and uncertainty associated with their exploitation.

| Challenge | Description |

| Heterogeneity in Fracture Networks | Fracture networks are often complex and irregular, leading to uneven fluid flow and unpredictable reservoir behavior. |

| Accurate Characterization | Difficulty in accurately mapping and characterizing fractures and matrix properties, affecting reservoir modeling and simulation. |

| Fluid Flow Prediction | Complicated by the dual-porosity system (fractures and matrix), making it challenging to predict flow rates and recovery. |

| Well Placement & Design | Determining optimal well locations and orientations to intersect productive fractures is challenging due to the variability in fracture distribution. |

| Pressure Management | Maintaining reservoir pressure and avoiding premature water or gas breakthrough is difficult, especially with interconnected fractures. |

| Reservoir Simulation | Traditional reservoir models may not effectively capture the behavior of fractured reservoirs, requiring specialized oil and gas simulation techniques. |

| Enhanced Recovery Techniques | Implementing EOR techniques, such as hydraulic fracturing or CO2 injection, is complex due to the interaction with existing natural fractures. |

| Operational Risks | Higher operational risks, including wellbore instability, fracture collapse, and unexpected fluid influxes, increase the complexity of development. |

| Economic Viability | High costs associated with advanced technologies and the uncertainties in recovery rates may affect the economic feasibility of developing fractured reservoirs. |

| Environmental Concerns | Potential environmental impacts, such as induced seismicity from hydraulic fracturing and groundwater contamination, require careful management. |

Techniques for Exploiting Fractured Reservoirs

Exploiting fractured reservoirs requires specialized techniques due to the complex nature of the fracture networks and the often dual-porosity system, where fluid storage and flow occur both within the fractures and the surrounding rock matrix.

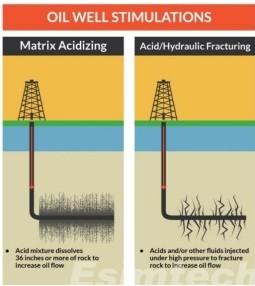

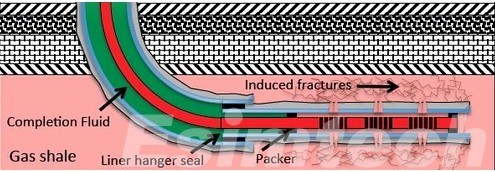

1. Hydraulic Fracturing

Description: Involves the injection of high-pressure fluid into the reservoir to create new fractures or extend existing ones. This technique enhances the connectivity between fractures, improving fluid flow and increasing recovery rates.

Application: Widely used in both oil and gas reservoirs to increase production by improving the permeability of the rock.

2. Horizontal and Multilateral Drilling

Description: Horizontal drilling involves drilling wells horizontally through the reservoir, intersecting multiple fractures. Multilateral drilling extends this by creating multiple horizontal branches from a single well.

Application: Maximizes reservoir contact, particularly in reservoirs with extensive natural fracture networks, leading to higher production rates.

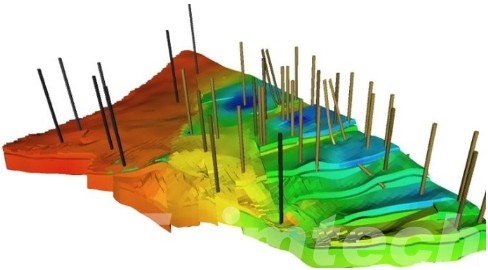

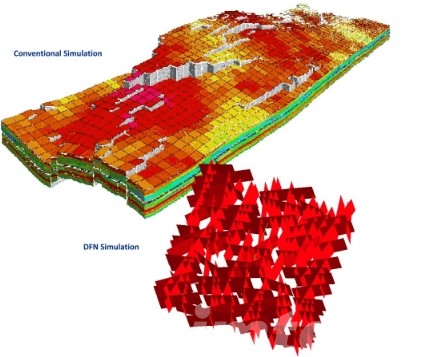

3. Reservoir Simulation

Description: Reservoir simulation Uses advanced simulation models (such as dual-porosity and dual-permeability models) to predict fluid flow and optimize production strategies. These models help in understanding how oil, gas, and water move through the complex fracture networks.

Application: Critical for planning and optimizing recovery techniques, especially in heterogeneous and complex reservoirs.

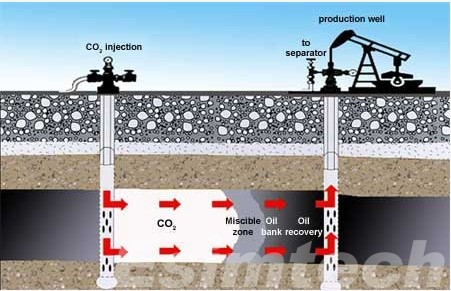

4. Enhanced Oil Recovery (EOR) Techniques

Description: EOR methods, such as CO2 injection, water flooding, or chemical flooding, are tailored to fractured reservoirs to improve oil displacement and increase recovery.

Application: Used in the later stages of reservoir life to extract additional oil that cannot be recovered through primary or secondary methods.

5. Microseismic Monitoring

Description: Involves the use of microseismic technology to monitor fracture propagation and reservoir response in real-time during hydraulic fracturing or other stimulation activities.

Application: Helps in optimizing fracturing treatments and understanding the effectiveness of stimulation techniques.

6. Matrix Acidizing

Description: Matrix acidizing involves injecting acid into the reservoir to dissolve minerals within the rock matrix, thereby enhancing permeability and improving the flow of fluids from the matrix to the fractures.

Application: Particularly useful in carbonate reservoirs where the matrix is often less permeable than the fractures.

7. Well Placement Optimization

Description: Advanced geological and geophysical techniques are used to determine optimal well locations and orientations to maximize intersection with productive fractures.

Application: Ensures that drilling targets the most productive areas of the reservoir, improving overall recovery efficiency.

8. Pressure Maintenance

Description: Involves the injection of fluids into the reservoir to maintain pressure, supporting continuous production and preventing the collapse of fractures.

Application: Used in reservoirs where natural pressure support is insufficient, particularly in the later stages of production.

9. Geomechanical Modeling

Description: Geomechanical models are employed to predict how the reservoir rock will respond to drilling, production, and stimulation activities. This helps in avoiding issues like fracture collapse or sand production.

Application: Crucial for ensuring the long-term stability and productivity of wells in fractured reservoirs.

10. Reservoir Characterization

Description: Reservoir characterization Involves the integration of seismic data, well logs, core samples, and other geological information to accurately map the fracture network and understand the reservoir’s properties.

Application: Provides a detailed understanding of the reservoir, which is essential for designing effective exploitation strategies.

Future Directions in Fractured Reservoir Development

The development of fractured reservoirs is an evolving field, with new technologies and strategies continuously being explored to overcome challenges and improve recovery rates.

1. Advanced Reservoir Modeling and Simulation

Future Focus: Development of more sophisticated models that can accurately predict the behavior of fluids in complex fracture networks. This includes integrating machine learning and artificial intelligence (AI) to enhance model accuracy and predictive capabilities.

Impact: Improved decision-making for well placement, production strategies, and reservoir management, leading to optimized recovery and reduced operational risks.

2. Enhanced Imaging and Fracture Characterization

Future Focus: Advances in seismic imaging, such as full-waveform inversion (FWI) and microseismic monitoring, will provide more detailed and accurate mapping of fracture networks. Additionally, the use of fiber-optic technologies like Distributed Acoustic Sensing (DAS) could offer real-time insights into fracture behavior.

Impact: Better understanding of fracture geometry and distribution, enabling more precise targeting of drilling and stimulation activities.

3. Nanotechnology for EOR

Future Focus: The application of nanotechnology in enhanced oil recovery (EOR) to develop nanoparticles that can navigate complex fracture networks, improving oil displacement and recovery. Nanoparticles could also be used for real-time reservoir monitoring and diagnostics.

Impact: Increased efficiency of EOR techniques, leading to higher recovery rates and prolonged reservoir life.

4. Smart Drilling and Completion Technologies

Future Focus: The integration of smart technologies, such as autonomous drilling systems and real-time downhole sensors, to enhance the precision and efficiency of drilling and completion operations in fractured reservoirs.

Impact: Reduced drilling risks, optimized well placement, and improved management of complex fracture networks.

5. Sustainable and Low-impact Recovery Methods

Future Focus: Development of environmentally friendly and sustainable recovery techniques, such as the use of CO2 sequestration combined with enhanced oil recovery (CO2-EOR), which can simultaneously reduce carbon emissions and enhance oil recovery.

Impact: Meeting environmental regulations and reducing the carbon footprint of hydrocarbon extraction while maintaining economic viability.

6. Reservoir Management Through Machine Learning and AI

Future Focus: Leveraging machine learning and AI to analyze large datasets from fractured reservoirs, providing insights for optimizing production strategies, predicting reservoir behavior, and enhancing decision-making.

Impact: Improved reservoir management, enhanced production efficiency, and the ability to respond more quickly to changes in reservoir conditions.

7. Geomechanical Analysis and Real-time Monitoring

Future Focus: Advances in geomechanical modeling and real-time monitoring techniques to better understand and predict the mechanical behavior of fractured reservoirs, particularly in response to stimulation and production activities.

Impact: Minimizing risks such as fracture collapse or sand production, ensuring the long-term stability and productivity of wells.

8. Integrated Multiphase Flow Simulation

Future Focus: Development of integrated multiphase flow simulation tools that can accurately model the movement of oil, gas, and water through complex fracture networks and porous rock matrices.

Impact: Enhanced understanding of fluid dynamics in fractured reservoirs, leading to more effective recovery strategies and better management of water and gas production.

9. Hydraulic Fracturing Optimization

Future Focus: Continued research into optimizing hydraulic fracturing techniques, including the use of tailored fracturing fluids, advanced proppants, and fracture network design, to maximize connectivity and recovery.

Impact: More efficient and cost-effective hydraulic fracturing operations, with reduced environmental impact and improved production outcomes.

In summary, the complexity of fractured reservoirs requires a deep understanding of fracture networks, advanced technologies, and innovative approaches to maximize recovery. As technology continues to advance, the exploitation of fractured reservoirs will lead to more efficient and sustainable hydrocarbon production.