How to Do Oil Rig Construction: A Comprehensive Guide

Oil rig construction is a spectacular feat of engineering that feeds the world’s insatiable desire for energy. These massive tasks, which are often built in the middle of large oceans, are vital to the extraction of petroleum resources, which power companies, economies, and modern lifestyles. In this essay, we delve into the complexities of oil rig construction, investigating the method, process, obstacles, and innovations involved in the creation of these offshore marvels.

Understanding Oil Rig Construction

Oil rig construction is a complicated task that involves rigorous planning, cutting-edge technology, and a professional team. The major goal is to build a robust platform that can survive the severe conditions of the open sea while also making it easier to recover oil and gas riches beneath the ocean floor. There are two main types of oil rigs: fixed platforms and floating structures.

Fixed Platforms

These rigs are appropriate for shallow waters because they are anchored to the ocean floor. They are made out of a steel or concrete base that spans from the bottom to the surface of the water. These platforms are most typically employed in calm, shallow waters where the seafloor provides a stable foundation.

Floating Structures

Floating rigs are intended for use in deeper oceans when fixed platforms are impractical. Semisubmersibles, drillships, and tension leg platforms (TLPs) are the different types of constructions. To ensure stability, they employ a combination of buoyancy and mooring devices.

Detailed Process of Oil Rig Construction

Oil rig construction is a spectacular achievement that necessitates teamwork among engineers, designers, technicians, and a wide range of trained individuals.

1. Pre-Construction Planning and Design

Thorough planning and design are required before construction begins to guarantee that the oil rig meets operating requirements while also adhering to safety and environmental norms.

Feasibility Study: .Engineers and project managers assess the project’s feasibility by taking into account elements such as water depth, seabed conditions, environmental impact, and economic viability.

Design Development: The structural layout, equipment location, and safety features are all detailed engineering designs. To develop precise blueprints, computer-aided design (CAD) software is employed.

2. Fabrication of Components

Oil rigs are made up of many components, each of which serves a distinct purpose. These components are built off-site and then delivered to the rig for assembly.

Foundation: The foundation is built initially for stationary platforms. This entails constructing the jacket structure, which is made up of vertical legs and horizontal braces. Typically, the jacket is built onshore, often in pieces, and then moved to the rig location for installation.

Superstructure: The superstructure includes the living quarters, drilling equipment, processing facilities, and other essential components. These components are fabricated off-site and often in specialized facilities to ensure precision and quality.

3. Assembly and Integration

When the components are finished, they are hauled to the rig site and assembled before being integrated into the overall structure.

Foundation Installation: For fixed platforms, the foundation components are transported to the site and installed using specialized vessels that can lift and position the massive structures accurately.

Superstructure Integration: The components of the superstructure are hoisted and put on top of the foundation. Cranes and heavy-lift equipment are utilized to position each item precisely.

4. Installation of Equipment

After the basic structure is in place, the installation of drilling, extraction, and processing equipment begins.

Drilling Equipment: The drilling equipment includes the drilling rig, derrick, drill pipes, and other equipment necessary for drilling into the ocean floor to access oil and gas reserves.

Processing Facilities: Oil, gas, and water separation facilities have been installed. Separators, pumps, compressors, and storage tanks are examples of these.

Living Quarters: The crew’s accommodations have been put up, complete with amenities such as sleeping quarters, dining sections, recreation rooms, and medical facilities.

5. Safety and Testing

Ensuring the safety of personnel and the environment is a paramount concern in oil rig construction.

Safety Systems: Fire detection and suppression equipment, emergency shut-off valves, and evacuation routes are installed and tested on the rig.

Testing and Simulations: Various systems, including drilling operations and emergency procedures, are tested through oil and gas simulators to ensure readiness for operational use.

6. Transportation and Installation

The final completed construction for floating rigs is delivered to the predetermined place in the open sea.

Towing and Positioning: Floating rigs are towed to their location and positioned using sophisticated mooring systems. Dynamic positioning technology allows these rigs to remain stationary despite currents and waves.

7. Commissioning and Operation

Following installation, the rig goes through commissioning, which includes final testing and adjustments to ensure that all systems are working properly.

Drilling Operations: The rig is ready for drilling activities once it has been commissioned. Oil and gas are extracted from the ocean floor using advanced drilling techniques and technologies.

8. Maintenance and Upgrades

Oil rigs must be maintained on a regular basis and may be upgraded to improve efficiency, safety, and environmental performance.

Routine Maintenance: Regular inspections, maintenance, and repairs are performed to ensure the integrity and safety of the rig.

Technological Upgrades: Rigs can be upgraded when new technologies arise including automation, data analytics, and remote monitoring systems.

Challenges and Innovations for Oil Rig Construction

Oil rig construction remains a vibrant industry that accepts challenges with creativity. n. As technology evolves, the industry continuously seeks innovative solutions to enhance safety, efficiency, and environmental responsibility.

Challenges in Oil Rig Construction

Harsh Environmental Conditions: Rigs are subjected to harsh weather, rough seas, and corrosive saltwater in offshore areas. These conditions necessitate strong designs and materials that can resist constant exposure.

Safety Concerns: Because of high-pressure drilling, heavy machinery, and complex systems, rig operations are inherently dangerous. A major problem is to ensure worker safety while reducing environmental effect.

Logistics: Transporting large rig components to remote offshore locations is a logistical nightmare. Transportation delays or disasters might result in significant cost overruns.

Depth and Pressure: Because of the immense pressures and depths involved, deepwater drilling poses technical problems. To deal with these harsh conditions, engineering solutions must be designed.

Regulatory Compliance: Environmental standards govern how rigs are built, operated, and eventually dismantled. Compliance with these regulations necessitates precise preparation and implementation.

Innovations in Oil Rig Construction

Advanced Materials: Materials science advancements have resulted in the creation of corrosion-resistant alloys, high-strength steels, and composite materials that increase the lifespan of rigs operating in hostile conditions.

Automation and Robotics: Automation and robotics have changed rig operations. Drones, remote-controlled vehicles (ROVs), and autonomous systems are employed for inspections, maintenance, and even drilling, eliminating human risk.

Digital Twin Technology: Creating digital replicas of physical rigs, known as digital twins, enables real-time monitoring, predictive maintenance, and scenario simulations of drilling and well control. This technology enhances decision-making and optimizes operations.

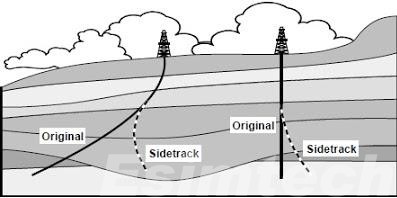

Drilling Technologies: Directional drilling and extended-reach drilling techniques allow for accessing reservoirs from a single location, reducing the need for multiple wells and minimizing the environmental footprint.

Subsea Systems: Subsea production techniques entail placing equipment on the seafloor, lowering rig visibility, and minimizing environmental effects. These methods allow for efficient harvest and processing while also protecting ocean ecosystems.

Environmental Mitigation: Waste management, water treatment, and spill response systems may reduce the impact of rig activities on marine ecosystems. Such developments include biodegradable drilling fluids and improved leak detection systems.

Digitalization and Data Analytics: Big data and analytics are critical for optimizing operations. Predictive analytics can predict equipment failures, allowing for preventative maintenance and reducing downtime.

Hybrid Energy Solutions: Integrating renewable energy sources into rig operations, such as wind or solar power, minimizes reliance on fossil fuels and reduces greenhouse gas emissions.

Smart Sensors and IoT: The use of smart sensors and Internet of Things (IoT) devices throughout rigs improves real-time monitoring of equipment conditions, allowing for prompt maintenance and risk reduction.

Conclusion

Oil rig construction requires a rare combination of engineering skill, technological innovation, and environmental awareness. These colossal constructions, whether permanent platforms or floating wonders, are critical to supplying the world’s energy demands.