How to Do Evaluation and Diagnostics in Well Cementing Effectively

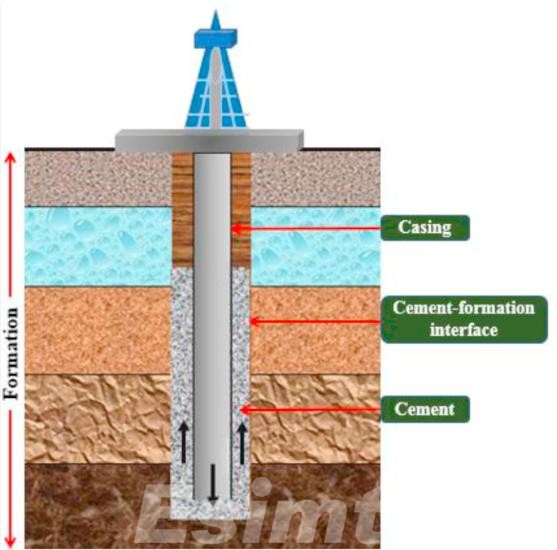

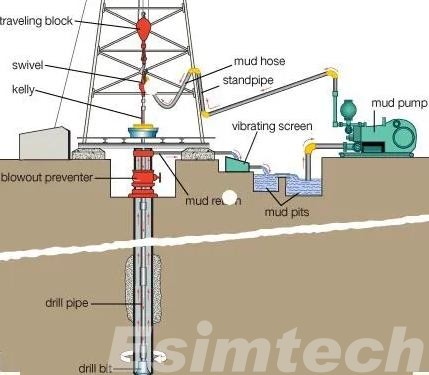

Well cementing is serving as the backbone for well integrity and long-term production efficiency in oil and gas operations, ensuring the isolation of different subterranean formations and providing structural support to the wellbore. Evaluation and diagnostics in well cementing are essential to ensure the operation is successful and to prevent potential issues that could compromise the well.

Importance of Evaluation and Diagnostics in Well Cementing

| Aspect | Importance |

| Well Integrity | Ensures proper zonal isolation, preventing fluid migration between formations and maintaining long-term well stability. |

| Operational Safety | Identifies potential risks such as weak bonds or channels that could lead to blowouts, allowing for corrective actions before problems escalate. |

| Cost Efficiency | Prevents costly remedial operations by detecting issues early, reducing the likelihood of expensive well repairs or interventions. |

| Regulatory Compliance | Helps meet regulatory requirements by providing evidence of proper cement placement and well integrity, avoiding fines or shutdowns. |

| Environmental Protection | Prevents contamination of groundwater or surface water by ensuring that hydrocarbons or other fluids do not migrate from the wellbore. |

| Enhanced Production | Maintains the integrity of the production zone by preventing the ingress of unwanted fluids, leading to more efficient and effective resource extraction. |

| Prolonged Well Life | Extends the life of the well by ensuring that the cement sheath remains intact and functional over time, minimizing the need for premature abandonment. |

| Data-Driven Decisions | Provides critical information for making informed decisions regarding well operations, maintenance, and future drilling activities. |

| Improved Cement Job Design | Allows for the optimization of cement slurry properties and placement techniques based on previous evaluation results, leading to better cement jobs in future operations. |

Common Evaluation Techniques in Well Cementing

1. Cement Bond Logs (CBL)

- Purpose: Cement Bond Logs (CBLs) are used to evaluate the quality of the bond between the casing and the cement and between the cement and the formation.

- How It Works: CBLs use acoustic signals to measure the acoustic impedance of the cement. A strong bond produces a high amplitude signal, while a poor bond results in low amplitude, indicating potential channels or voids.

- Applications: CBLs are commonly used to verify that the cement has properly filled the annulus and is effectively isolating different geological formations.

2. Ultrasonic Imaging Tools (USIT)

- Purpose: Ultrasonic Imaging Tools provide high-resolution images of the wellbore and the cement sheath, offering a more detailed evaluation than CBLs alone.

- How It Works: These tools use ultrasonic pulses to create an image of the cement sheath, which can reveal small-scale defects like micro-annuli or unbonded sections.

- Applications: USITs are particularly useful in complex wells where a detailed understanding of cement integrity is critical.

3. Temperature Logs

- Purpose: Temperature logs are used to detect the top of the cement and identify potential channels in the cement by measuring temperature changes over time.

- How It Works: As the cement sets, it generates heat. Temperature logs track the thermal profile of the well, with anomalies indicating areas where the cement might not be properly set.

- Applications: This technique is often used in combination with CBLs to provide a more comprehensive assessment of cement placement and integrity.

4. Gamma Ray Logs

- Purpose: Gamma ray logs track the placement of radioactive tracers added to the cement slurry, helping to ensure that the cement is properly placed.

- How It Works: By measuring the gamma radiation levels in the wellbore, operators can identify the location and extent of the cement, confirming that it has been properly distributed.

- Applications: This method is used primarily when there is a need to confirm the top of the cement or to identify the presence of channels or voids.

5. Pressure Testing

- Purpose: Pressure testing evaluates the ability of the cement to withstand formation pressures and detect any leaks or weak spots.

- How It Works: After the cement has been set, pressure is applied to the well, and any pressure drops are monitored to identify potential failures in the cement sheath.

- Applications: Pressure testing is a straightforward method that provides immediate feedback on the effectiveness of the cement job.

Diagnostic Methods for Failures in Well Cementing

Failures in well cementing can lead to significant issues, including compromised well integrity, fluid migration, and even catastrophic blowouts. Diagnosing these failures is crucial for identifying the root causes and implementing corrective measures.

1. Caliper Logging

- Purpose: To assess wellbore geometry and identify potential issues that could affect cementing.

- How It Works: Caliper logs measure the diameter of the wellbore, revealing washouts, undergauged sections, or other irregularities that could compromise cement placement.

- Application: Caliper logs are essential in diagnosing mechanical issues with the wellbore that could lead to poor cement coverage or bonding.

2. Fluid Sampling and Analysis

Purpose: To identify contamination in the cement slurry or fluid migration behind the casing.

How It Works: Fluid samples are taken from the wellbore or annulus and analyzed for signs of contamination, such as the presence of drilling mud or formation fluids in the cement.

Application: Fluid analysis can help diagnose issues like incomplete displacement, poor slurry mixing, or contamination that could weaken the cement sheath.

3. Acoustic Leak Detection

Purpose: To detect small leaks or channels in the cement sheath by listening for sound generated by fluid movement.

How It Works: Acoustic sensors are lowered into the well to listen for the distinctive sounds of fluid moving through small channels or leaks in the cement.

Application: This method is particularly useful in detecting small, hard-to-find leaks that might not be apparent through other diagnostic methods.

Simulations Used in Evaluation and Diagnostics of Well Cementing

Simulations play a crucial role in the evaluation and diagnostics of well cementing by allowing operators to predict potential issues, optimize cement designs, and validate the integrity of the cement job.

1. Cement Placement Simulation

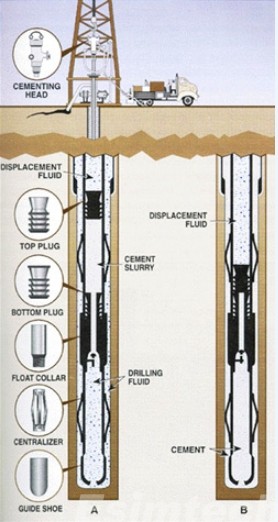

- Purpose: To model the displacement of drilling mud by cement slurry in the annulus and predict the effectiveness of the cement placement.

- How It Works: This simulation uses fluid dynamics to analyze how the cement will flow into the wellbore, considering factors like the viscosity of the fluids, wellbore geometry, and flow rates. It helps in predicting the likelihood of complete mud removal and uniform cement placement.

- Applications: This simulation is crucial for optimizing cement designs and displacement techniques to ensure complete zonal isolation and avoid channeling or mud contamination.

2. Thermal Simulations

- Purpose: To predict the temperature profile of the wellbore during and after cementing, which affects the cement setting process and the development of the cement’s mechanical properties.

- How It Works: Thermal simulations model the heat generated by the hydration of cement and its impact on wellbore temperatures. These simulations help in understanding how temperature variations could lead to differential expansion, cracking, or improper setting of the cement.

- Applications: Thermal simulations are particularly useful in wells with high-temperature gradients or where the cement’s thermal properties are critical for maintaining well integrity.

3. Stress Analysis Simulations

- Purpose: To evaluate the mechanical stresses that the cement sheath will experience during different stages of the well’s life, including drilling, production, and potential thermal cycling.

- How It Works: These simulations model the mechanical response of the cement to changes in pressure, temperature, and other operational conditions. They help predict potential failure points, such as micro-annuli formation, cracking, or debonding from the casing or formation.

- Applications: Stress analysis is vital for designing cement formulations that can withstand the anticipated mechanical loads and for planning operational procedures that minimize the risk of cement failure.

4. Fluid Loss Simulations

- Purpose: To predict the loss of cement slurry to the formation during placement, which can lead to incomplete cement coverage and poor zonal isolation.

- How It Works: These simulations model the interaction between the cement slurry and the surrounding formations, including factors like formation permeability, pressure differentials, and slurry properties. The results help in optimizing slurry design and placement techniques to minimize fluid loss.

- Applications: Fluid loss simulations are particularly important in formations that are highly permeable or fractured, where significant fluid loss can compromise the quality of the cement job.

5. Acoustic and Ultrasonic Response Simulations

- Purpose: To predict the acoustic and ultrasonic response of the cemented wellbore, aiding in the interpretation of Cement Bond Logs (CBLs) and Ultrasonic Imaging Tools (USITs) data.

- How It Works: These simulations model how acoustic or ultrasonic waves propagate through the wellbore and the cement sheath, considering factors like cement density, bond quality, and the presence of micro-annuli or channels. The simulated data is used to calibrate and validate the results from logging tools.

- Applications: These simulations are essential for improving the accuracy of wellbore diagnostics and for distinguishing between different types of cement defects or issues.

6. Gas Migration Simulations

- Purpose: To assess the potential for gas migration through or around the cement after placement, which can lead to safety hazards and compromised well integrity.

- How It Works: Gas migration simulations model the movement of gas within the wellbore, considering the cement’s permeability, setting time, and the presence of any channels or micro-annuli. These simulations help in designing cement slurries and placement techniques that minimize the risk of gas migration.

- Applications: Gas migration simulations are particularly important in wells with high gas pressures or where the cement needs to provide an immediate seal to prevent gas ingress.

In summary, the combination of thorough evaluation, advanced diagnostic techniques, and real-time monitoring forms the cornerstone of effective well cementing. By adopting these practices, operators can significantly reduce the risk of well failure, ensuring safer and more efficient operations.