How to Do Effective Methane Leak Detection in the Oil and Gas Industry

Methane is a potent greenhouse gas, with a significantly higher global warming potential than carbon dioxide over a short period. In the oil and gas industry, methane leaks can occur at various stages of production, processing, and distribution, making detection and mitigation critical for environmental and economic reasons. Effective methane leak detection helps reduce emissions, improve safety, and ensure regulatory compliance.

Importance of Methane Leak Detection in the Oil and Gas Industry

Methane leaks in the oil and gas industry pose a dual challenge: they represent a loss of valuable product and contribute to climate change. According to the International Energy Agency (IEA), the oil and gas sector accounts for nearly 40% of global methane emissions from human activities. Detecting and repairing these leaks is essential for:

- Environmental Protection: Reducing methane emissions is a key strategy in combating climate change and meeting global climate targets, such as those outlined in the Paris Agreement.

- Economic Efficiency: Methane leaks represent lost revenue for companies. Detecting and repairing leaks can save millions of dollars annually.

- Regulatory Compliance: Governments and international organizations are increasingly implementing stricter regulations to limit methane emissions, making leak detection a legal necessity.

Common Sources of Methane Leaks in the Oil and Gas Industry

| Source | Description |

| Wellheads and Well Casings | Leaks can occur due to faulty seals, aging infrastructure, or pressure buildup during drilling and extraction. |

| Pipelines | Methane can escape through cracks, corrosion, or loose fittings in transmission and distribution pipelines. |

| Compressor Stations | Equipment used to maintain pressure during gas transport may leak due to worn seals or mechanical failures. |

| Storage Tanks | Methane can leak from venting systems, faulty valves, or structural weaknesses in above-ground and underground storage. |

| Processing Facilities | Equipment used for gas separation, drying, and refining may release methane through leaks in valves, flanges, and joints. |

| Flaring and Venting Systems | Incomplete combustion during flaring or unintentional venting of methane can lead to significant emissions. |

| Abandoned and Orphaned Wells | Inactive wells that are improperly sealed or left unmonitored may release methane into the atmosphere. |

| Liquefied Natural Gas (LNG) Terminals | Methane leaks can occur during liquefaction, storage, and transfer due to handling errors or equipment malfunctions. |

| Pneumatic Devices | Devices that control pressure and flow may release methane during normal operations or due to malfunctions. |

| Equipment Leaks (Fugitive Emissions) | Small but consistent leaks can emerge from faulty gaskets, seals, and other connections throughout the system. |

Key Methods for Methane Leak Detection in the Oil and Gas Industry

1. Optical Gas Imaging (OGI) Cameras

Optical Gas Imaging (OGI) cameras have emerged as a powerful tool for methane leak detection. Utilizing infrared technology, these cameras visualize methane leaks as visible plumes, allowing operators to identify and address issues in real-time. OGI cameras are particularly effective for routine inspections and troubleshooting, as they provide immediate visual confirmation of leaks. However, their high cost and the need for skilled operators can limit widespread adoption, especially among smaller operators.

2. Drone-Based Monitoring

Drones equipped with methane sensors or OGI cameras are revolutionizing the way leaks are detected in the oil and gas industry. These unmanned aerial vehicles can quickly survey large areas, including hard-to-reach locations such as offshore platforms or remote pipelines. Drone-based monitoring offers a cost-effective and efficient alternative to manual inspections, reducing the time and labor required for comprehensive surveys. Additionally, drones can be deployed in hazardous environments, minimizing risks to personnel.

3. Satellite Monitoring

Satellite technology has taken methane leak detection to a global scale. Satellites equipped with advanced sensors, such as those used in the European Space Agency’s Sentinel-5P or private-sector initiatives like GHGSat, can detect methane emissions from space. This capability is particularly valuable for identifying large leaks and monitoring emissions across vast regions. Satellite data can also complement ground-based measurements, providing a more comprehensive picture of methane emissions.

4. Fixed and Mobile Sensors

Ground-based fixed sensors and vehicle-mounted mobile systems offer continuous monitoring of methane levels in specific areas. These sensors provide real-time data, enabling operators to quickly identify and respond to leaks. Fixed sensors are often installed at key points in the infrastructure, such as wellheads or compressor stations, while mobile systems can be used for periodic surveys. The integration of these sensors into broader monitoring networks enhances their effectiveness and provides a more robust detection system.

5. Laser-Based Detection

Laser-based technologies, such as tunable diode laser absorption spectroscopy (TDLAS), have become a cornerstone of methane leak detection. These systems use laser beams to measure methane concentrations with high precision, making them ideal for continuous monitoring at facilities. TDLAS systems are often deployed in areas where real-time, accurate measurements are critical, such as natural gas processing plants or storage facilities. Their ability to provide instant feedback makes them invaluable for maintaining operational safety and environmental compliance.

6. Artificial Intelligence (AI) and Data Analytics

The integration of artificial intelligence (AI) and data analytics into methane leak detection is transforming the industry. AI-powered software can analyze vast amounts of data from various sensors, identifying patterns and anomalies that may indicate leaks. Machine learning algorithms improve over time, enhancing the accuracy and efficiency of detection processes. These technologies also enable predictive maintenance, allowing operators to address potential issues before they escalate into significant leaks.

Challenges and Future Directions in Methane Leak Detection

| Challenge | Description | Future Directions |

| Sensitivity and Accuracy | Difficulty in detecting low-concentration methane leaks with high precision, leading to potential missed leaks. | Development of highly sensitive sensors with improved detection capabilities for low-concentration methane leaks. |

| Remote Area Monitoring | Challenges in monitoring methane leaks in remote or hard-to-reach locations, such as offshore platforms and pipelines in remote regions. | Use of drones and satellite-based technologies for real-time detection and monitoring of methane leaks in remote and offshore areas. |

| Harsh Environmental Conditions | Extreme weather, temperature fluctuations, and other environmental factors can impact the performance of detection systems. | Creation of weatherproof and durable sensors designed to operate in extreme temperatures, humidity, and rugged environments. |

| Data Overload and Analysis | Large volumes of data generated by detection systems can overwhelm traditional analysis methods, leading to delays in leak identification. | Implementation of AI-driven analytics and cloud-based platforms for real-time data analysis and decision-making. |

| False Positives | Some detection methods may result in false positives due to interference from other gases or environmental factors, requiring more sophisticated systems. | Integration of advanced algorithms to reduce false positives caused by other gases or environmental factors. |

| High Operational Costs | Advanced methane detection technologies can be expensive to install, maintain, and operate, especially for large-scale infrastructure. | Adoption of low-cost, automated detection systems and integrated monitoring solutions to reduce long-term operational expenses. |

| Leak Quantification | Difficulty in accurately quantifying methane leaks, which affects emission reporting and regulatory compliance. | Improved methods for precise leak quantification, utilizing advanced sensors and data modeling techniques to measure emissions accurately. |

| Equipment Reliability and Durability | Detection equipment can degrade over time, particularly in rugged environments, leading to less reliable results. | Development of long-lasting, self-calibrating systems that require minimal maintenance and are resistant to wear and tear in challenging conditions. |

| Integration with Existing Infrastructure | Challenges in integrating new detection technologies with existing pipeline systems and older equipment. | Creation of modular, retrofit-friendly solutions that can easily integrate with existing infrastructure for seamless monitoring. |

| Regulatory Compliance | Difficulty in meeting increasingly stringent regulatory requirements and ensuring compliance across diverse locations and operations. | Implementation of unified reporting standards and real-time compliance monitoring tools to ensure adherence to regulatory requirements. |

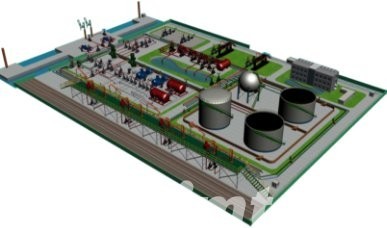

How Simulation Technologies are Used for Methane Leak Detection

Real-Time Data Integration

These technologies collect real-time data from various sensors, such as gas detectors and environmental monitors, and use this information to simulate the current conditions within pipelines or facilities. This allows operators to detect potential leak points and assess the severity of any leaks based on actual, up-to-date measurements.

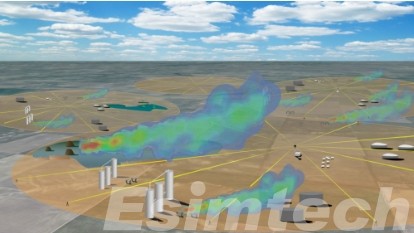

Predictive Analytics

Simulation models use predictive analytics to forecast future leak events by analyzing trends and environmental variables. This proactive approach allows for early detection, enabling operators to take preventive actions before leaks escalate. Simulation also aids in pinpointing the exact location of leaks by modeling how methane disperses through infrastructure under varying conditions, even in remote or difficult-to-reach areas.

Scenario Modeling and Optimization of Response Plans

By simulating different leak scenarios, such as varying leak sizes and weather patterns, these technologies help operators assess the potential impact of leaks and plan appropriate responses. Furthermore, simulation systems optimize emergency response strategies, guiding operators in containing or mitigating leaks efficiently and determining the best repair solutions. Integration of simulation technologies with monitoring systems also facilitates automated decision-making, triggering alerts or corrective actions without human intervention, improving safety and operational efficiency.

Overall, oil and gas simulation technologies provide a comprehensive approach to methane leak detection by enhancing the accuracy, timeliness, and effectiveness of responses in the oil and gas industry.

Summary

Methane leak detection is a critical aspect of environmental responsibility and improving operational efficiency in the oil and gas industry. With advancements in technology and growing regulatory pressure, the industry is making significant strides in identifying and addressing methane emissions. Through adopting advanced technologies such as OGI cameras, drones, IoT sensors, and AI-based systems, companies can effectively monitor and mitigate methane leaks contributing to a more sustainable energy future.