How to Address the Challenges in Well Completion

Well completion is used to determine the efficiency, safety, and productivity of a well throughout its lifespan. However, as reservoirs become more complex and environmental regulations tighten, the challenges associated with well completion have grown. Addressing these challenges requires a combination of advanced technologies, strategic planning, and innovative approaches.

Understanding the Challenges in Well Completion

This chart outlines the major challenges faced during well completion, highlighting the complexities involved in ensuring safe, efficient, and cost-effective operations.

| Challenge | Description |

| Complex Reservoirs | Dealing with heterogeneous, unconventional, or multi-layered reservoirs that require customized completion strategies. |

| Zonal Isolation | Ensuring that different zones within the well are effectively isolated to prevent cross-flow or contamination. |

| Pressure Management | Controlling and maintaining the well’s pressure to prevent blowouts, wellbore collapse, or other safety hazards. |

| Sand Production | Managing the production of sand, which can cause erosion, clogging, and damage to well equipment. |

| Environmental Impact | Minimizing the environmental footprint of well completion activities, including reducing water use and managing chemical use. |

| Well Integrity | Ensuring the structural integrity of the well throughout its life, preventing leaks, and maintaining safety. |

| Cost Management | Balancing the need for advanced technologies and materials with the economic constraints of the project. |

| Enhanced Oil Recovery (EOR) Implementation | Integrating EOR techniques effectively into well completion to maximize hydrocarbon recovery without compromising well integrity. |

Key Advanced Technologies to Overcome the Challenges in Well Completion

1. Adopting Multilateral Well Completions

Multilateral well completions offer a solution to the challenge of accessing complex reservoirs. By drilling multiple lateral branches from a single main wellbore, operators can access multiple zones within a reservoir, maximizing contact with the hydrocarbon-rich layers. This approach not only increases production potential but also reduces the number of surface facilities required, leading to cost savings and a smaller environmental footprint.

2. Expandable Tubulars and Advanced Packers

Zonal isolation is critical to prevent the mixing of fluids from different reservoir zones, which can compromise production efficiency and well integrity. Expandable tubular technology and advanced packers offer a robust solution. Expandable tubulars can be expanded in place within the wellbore, providing a secure seal between different zones. Advanced packers, on the other hand, are designed to withstand extreme conditions, ensuring effective isolation even in challenging environments.

3. Intelligent Completions

Intelligent completions, also known as smart completions, incorporate downhole sensors, control valves, and real-time data transmission systems. These technologies enable operators to monitor well conditions continuously and adjust pressure, flow rates, and other parameters remotely. By providing precise control over the well environment, intelligent completions help prevent blowouts, manage wellbore stability, and optimize production.

4. Advanced Sand Control Technologies

Managing sand production is crucial to protect well integrity and ensure continuous production. Advanced sand control technologies, such as gravel packing, frac packing, and sand screens, are designed to prevent sand from entering the wellbore while maintaining hydrocarbon flow. These techniques not only extend the life of the well but also reduce the need for costly maintenance and equipment replacement.

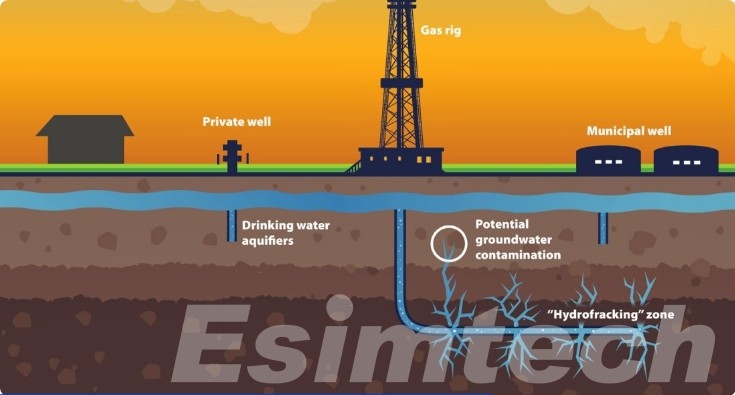

5. Low-Impact Hydraulic Fracturing

Environmental considerations are increasingly important in well completion. Low-impact hydraulic fracturing techniques, which use environmentally friendly fluids and optimized processes, help minimize the ecological footprint of well stimulation activities. Additionally, green completion techniques, such as capturing and reusing gases released during completion, further reduce the environmental impact.

6. Advanced Cementing Techniques

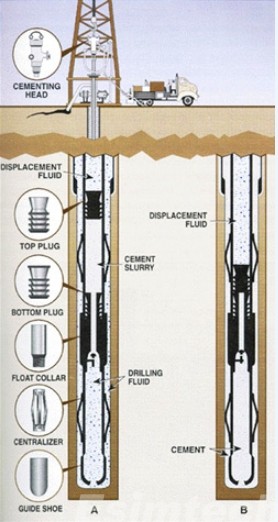

Advanced cementing techniques are essential for maintaining well integrity over the long term. High-performance cement formulations, coupled with precise placement methods, ensure a strong bond between the casing and the wellbore, preventing leaks and maintaining structural stability. This is particularly important in wells with high temperatures, pressures, or corrosive environments.

6. Digital Twin Technology

Cost management is a major concern in well completion, especially when deploying advanced technologies. Digital twin technology offers a solution by creating a virtual replica of the well and its completion process. This allows operators to test and optimize strategies in a virtual environment before implementation, reducing the risk of costly errors and interventions. Digital twins technology is used to simulate the different drilling and well control scenarios and also help in making informed decisions that balance performance with budget constraints.

Future Technological Developments in Well Completion

The future of well completion technologies is poised to be shaped by several emerging trends and innovations that aim to further enhance efficiency, reduce environmental impact, and address increasingly complex reservoirs.

1. Integration of Artificial Intelligence and Machine Learning

Development: AI and machine learning will play a significant role in automating well completion processes, predicting reservoir behavior, and optimizing completion designs in real-time.

Impact: Improved decision-making, reduced downtime, and enhanced accuracy in managing complex reservoirs.

2. Advanced Autonomous Downhole Tools

Development: The evolution of autonomous downhole tools capable of performing tasks such as zonal isolation, pressure monitoring, and even self-healing of wellbore damages without human intervention.

Impact: Increased efficiency, reduced need for well interventions, and extended well life.

3. Enhanced Materials and Coatings

Development: New materials and coatings that offer greater resistance to extreme temperatures, pressures, and corrosive environments.

Impact: Improved well integrity, reduced maintenance costs, and longer-lasting well infrastructure.

4. Nanotechnology Applications

Development: The use of nanomaterials in completion fluids, coatings, and downhole tools to enhance performance at a microscopic level.

Impact: Enhanced fluid properties, better control over wellbore stability, and improved sand control techniques.

5. Real-Time Reservoir Mapping and Characterization

Development: Advanced seismic and logging tools that provide real-time, high-resolution mapping of the reservoir during the completion process.

Impact: Better understanding of reservoir properties, enabling more precise and effective completion strategies.

6. Blockchain for Well Completion Data Security

Development: The application of blockchain technology to secure and streamline the management of data related to well completions, ensuring data integrity and transparency.

Impact: Enhanced data security, reduced chances of data tampering, and improved collaboration across stakeholders.

In summary, the challenges in well completion are numerous and complex, but they can be effectively addressed with the right combination of advanced technologies, strategic planning, and innovative approaches. Staying ahead of these challenges will require continuous innovation and adaptation. Adopting the latest technologies and best practices will not only help in addressing current challenges but also in preparing for the future of well completion.