How Rotary Steerable Systems Revolutionize Directional Drilling in the Oil and Gas Industry

The oil and gas industry relies on innovation to overcome challenges and optimize drilling operations. One such innovation that has revolutionized directional drilling is the rotary steerable system (RSS). These sophisticated drilling tools offer enhanced control, increased drilling speeds, and improved wellbore quality. Let’s delve into the intricacies of rotary steerable systems and their pivotal role in modern drilling endeavors.

Evolution of Rotary Steerable Systems

The concept of steering drill bits while rotating has been a goal of drilling engineers for decades. Early attempts at achieving this involved complex mechanical assemblies with limited success. However, significant advancements in electronics, sensors, and telemetry systems in the late 20th century paved the way for the development of practical rotary steerable systems.

The first commercially successful RSS rotary steerable system was introduced in the 1990s, marking a significant milestone in directional drilling technology. Since then, continuous research and development efforts have led to the refinement and proliferation of rotary steerable systems, with modern iterations boasting enhanced capabilities, reliability, and performance.

Key Components of Rotary Steerable Systems

1. Downhole Motor

At the heart of a rotary steerable system is a downhole motor. This motor generates the rotational force required to turn the drill bit while drilling. The downhole motor can be powered hydraulically, pneumatically, or electrically, depending on the specific design of the RSS.

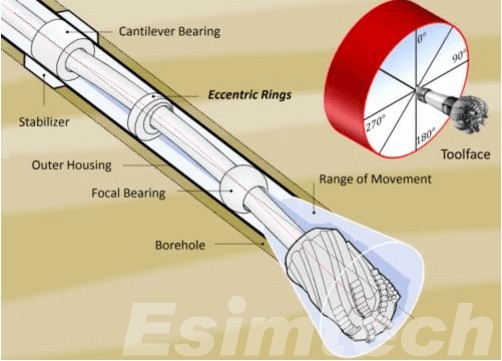

2. Steering Mechanism

The steering mechanism of an RSS is responsible for orienting the drill bit in the desired direction. This component allows the drill bit to be deflected and steered in real-time, enabling precise control over the wellbore trajectory. Hydraulic actuators or mechanical mechanisms are commonly used to adjust the orientation of the drill bit.

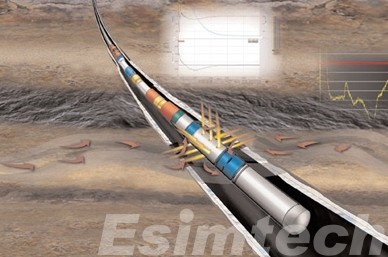

3. Sensors

Rotary steerable systems are equipped with an array of sensors that gather data on various drilling parameters, downhole conditions, and formation properties. These sensors include inclinometers, azimuthal gamma ray sensors, resistivity sensors, and accelerometers, among others. The data collected by these sensors is crucial for steering the drill bit accurately and monitoring drilling performance.

4. Telemetry Systems

Communication between the surface control unit and the downhole components of the rotary steerable system is facilitated by telemetry systems. These systems transmit commands from the surface to the downhole tool and relay real-time data back to the surface for monitoring and analysis. Telemetry can be achieved using mud pulse, electromagnetic, wired drill pipe, or acoustic methods, depending on the specific requirements of the drilling operation.

5. Control Software

Control software plays a critical role in the operation of rotary steerable systems. This software processes data from the downhole sensors, interprets input from the surface control unit, and calculates the adjustments required to steer the drill bit along the desired trajectory. Advanced algorithms are employed to optimize drilling performance and minimize deviation from the target path.

6. Power Supply

Rotary steerable systems require a reliable power supply to operate the downhole motor, steering mechanism, sensors, and telemetry systems. Depending on the design of the RSS, power may be supplied by batteries, hydraulic fluid, or electrical cables running through the drill string.

6. Bottom Hole Assembly (BHA)

The rotary steerable system is integrated into the bottom hole assembly, which also includes the drill bit, stabilizers, and other drilling tools. The BHA is lowered into the wellbore and is responsible for transmitting the rotational force from the downhole motor to the drill bit, as well as providing stability and support during drilling operations.

How Rotary Steerable Systems Function During Drilling Operations

The operation of rotary steerable systems involves a series of steps that enable precise directional drilling while rotating the drill string.

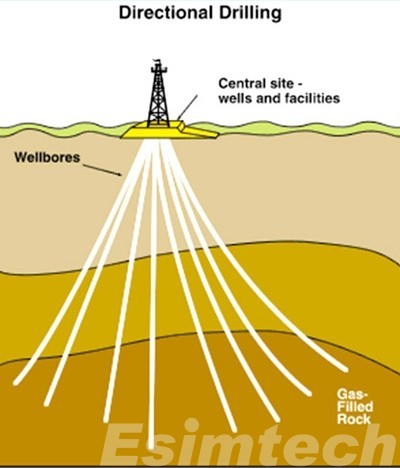

1. Planning and Programming

Before drilling begins, drilling engineers develop a drilling plan based on geological data, wellbore objectives, and reservoir targets. This plan includes the desired wellbore trajectory, which may involve vertical, deviated, or horizontal sections. Engineers use specialized software to program the rotary steerable system with instructions for steering the drill bit along the planned trajectory.

2. Deployment and Initialization

Once the drilling assembly is assembled and lowered into the wellbore, the rotary steerable system is initialized. This involves calibrating sensors, establishing communication with the surface control unit, and verifying the functionality of the downhole motor, steering mechanism, and telemetry systems.

3. Real-time Steering Control

As drilling progresses, the RSS continuously monitors drilling parameters such as weight on bit, torque, drilling fluid properties, and downhole conditions using its array of sensors. This real-time data is transmitted to the surface control unit via telemetry systems. Based on this data and input from drilling engineers, the steering mechanism of the RSS adjusts the orientation of the drill bit to stay on course with the predetermined trajectory. The system may employ various steering modes, such as sliding, rotating, or combinations of both, depending on the drilling conditions and objectives.

4. Dynamic Trajectory Adjustment

Throughout the drilling process, the rotary steerable system can dynamically adjust the wellbore trajectory in response to changes in formation properties, wellbore conditions, or drilling objectives. This flexibility allows operators to optimize drilling efficiency and navigate complex geological formations with precision. The control software of the RSS analyzes real-time data and makes adjustments to steer the drill bit towards the desired target while avoiding obstacles or hazards.

5. Monitoring and Analysis

Surface personnel monitor the data transmitted from the downhole sensors via telemetry systems. This data is analyzed to assess drilling performance, detect potential issues or hazards, and make informed decisions to optimize operations. The telemetry systems also allow for remote control of the RSS, enabling drilling engineers to adjust parameters and commands as needed to maintain drilling efficiency and wellbore integrity.

6. Retrieval and Evaluation

Upon reaching the target depth or completing the drilling operation, the rotary steerable system is retrieved from the wellbore. Data collected during the drilling process is analyzed to evaluate the success of the operation, assess wellbore quality, and inform future drilling activities. Lessons learned from the operation of the RSS are incorporated into future drilling plans and techniques to further enhance drilling performance and efficiency.

Future Outlook for Rotary Steerable Systems

1. Technological Advancements

Ongoing research and development efforts are focused on advancing the technology behind rotary steerable systems. This includes the development of more robust and reliable downhole components, such as improved sensors, actuators, and telemetry systems.

2. Integration with Automation and Artificial Intelligence (AI)

The integration of rotary steerable systems with automation and AI technologies is expected to revolutionize drilling operations. AI algorithms can analyze vast amounts of drilling data in real-time, providing insights into optimal drilling parameters, predicting downhole conditions, and optimizing wellbore trajectories. Automation capabilities enable autonomous drilling operations, reducing human intervention and enhancing drilling efficiency and safety.

3. Enhanced Drilling Performance in Challenging Environments

Rotary steerable systems are increasingly being deployed in challenging drilling environments, including deepwater, high-pressure/high-temperature (HPHT), and unconventional reservoirs. Future advancements in RSS technology will focus on addressing the unique challenges of these environments, such as extreme temperatures, high-pressure formations, and complex geological structures. Improved drilling efficiency and reliability in such environments will unlock new opportunities for exploration and production.

4. Environmental Sustainability

With growing emphasis on environmental sustainability, future developments in rotary steerable systems will focus on reducing the environmental footprint of drilling operations. This includes innovations in drilling fluids, downhole tools, and drilling techniques aimed at minimizing waste, reducing emissions, and mitigating environmental impact. RSS technology will play a crucial role in enabling more efficient and environmentally responsible drilling practices.

5. Integration with Digitalization and Data Analytics

The digitalization of drilling operations and the widespread adoption of data analytics platforms are transforming the way drilling data is collected, analyzed, and utilized. Rotary steerable systems generate vast amounts of data during drilling operations, and integrating RSS data with digital platforms allows for real-time monitoring, analysis, and optimization of drilling performance. Predictive analytics can anticipate potential drilling challenges and optimize drilling parameters to improve overall efficiency and wellbore quality.

6. Cost Reduction and Operational Efficiency

Future advancements in rotary steerable systems will continue to focus on reducing drilling costs and enhancing operational efficiency. By streamlining drilling processes, minimizing non-productive time, and maximizing drilling performance, RSS technology enables operators to achieve cost-effective well construction while maintaining high standards of safety and quality.

How Simulation is Used in Rotary Steerable Systems

Simulation plays a crucial role in the development, testing, and optimization of rotary steerable systems in the oil and gas industry.

1. Design and Engineering

Simulation tools are used in the design and engineering phase of rotary steerable systems to evaluate different configurations, components, and materials. Engineers can simulate the performance of downhole motors, steering mechanisms, sensors, and telemetry systems to optimize their design for reliability, efficiency, and durability. This iterative process allows engineers to identify potential design flaws, optimize performance parameters, and reduce development time and costs.

2. Drilling Performance Prediction

Simulation models are used to predict the drilling performance of rotary steerable systems under different drilling scenarios. By inputting parameters such as formation properties, wellbore geometry, drilling fluid properties, and operational parameters, engineers can simulate the drilling process and predict variables such as drilling rate, torque, weight on bit, and tool wear. These predictions help optimize drilling operations, select the most suitable RSS configuration, and anticipate potential drilling challenges.

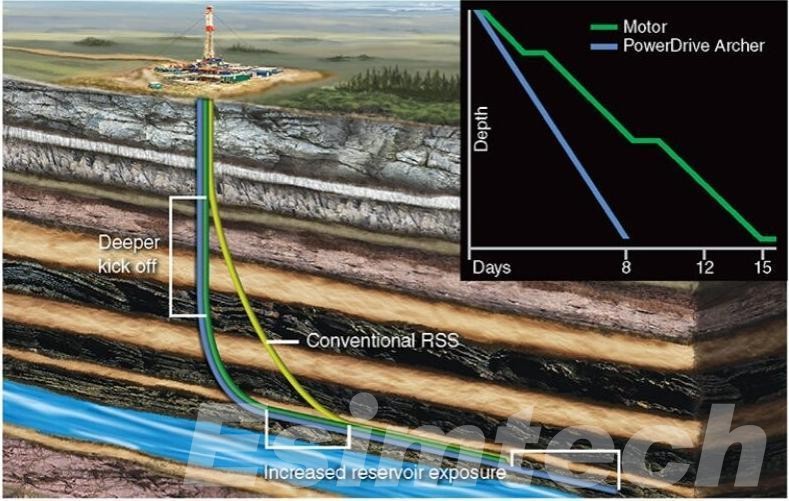

3. Trajectory Planning and Optimization

Simulation tools are used to plan and optimize wellbore trajectories when using rotary steerable systems. By simulating different steering strategies, drilling parameters, and formation properties, engineers can identify the most efficient trajectory to reach the target zone while avoiding obstacles and hazards. Trajectory optimization simulations help minimize drilling time, reduce drilling risks, and maximize reservoir exposure, ultimately enhancing well productivity and recovery.

4. Control System Development

Simulation is used to develop and test the control algorithms and software that govern the operation of rotary steerable systems. By simulating the interaction between downhole components, surface control units, and telemetry systems, engineers can evaluate the performance of the control system under various conditions and scenarios. This allows for the refinement of control algorithms to optimize steering accuracy, response time, and stability during drilling operations.

5. Failure Analysis and Risk Assessment

Simulation tools are used to perform failure analysis and risk assessment for rotary steerable systems. By simulating potential failure modes, such as motor overheating, sensor malfunction, or steering mechanism failure, engineers can assess the likelihood and consequences of equipment failures during drilling operations. This helps identify critical failure points, implement preventive maintenance strategies, and mitigate drilling risks.

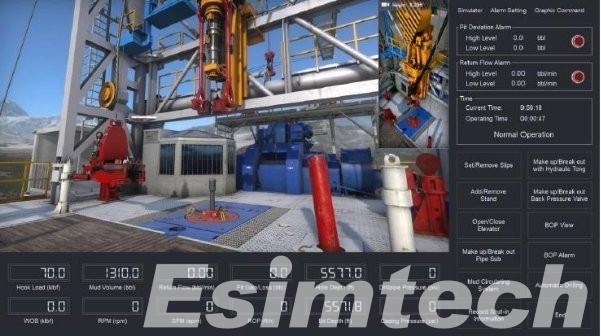

6. Training and Education

Simulation-based training programs are used to train drilling engineers and technicians in the operation and maintenance of rotary steerable systems. Virtual drilling simulators allow users to practice drilling operations in a realistic virtual environment, gaining hands-on experience without the risks and costs associated with actual drilling operations. Simulation-based training enhances operator competency, improves safety awareness, and reduces the likelihood of human error during drilling operations.

Conclusion

Rotary steerable systems represent a transformative innovation in the field of directional drilling, offering unparalleled precision, efficiency, and versatility. As the quest for hydrocarbon reserves ventures into ever more challenging environments, the evolution and integration of rotary steerable systems will remain vital to the success and sustainability of drilling endeavors.