How Much Do You Know About Unconventional Reservoirs

Unconventional reservoirs are geological formations that require advanced technologies and methods for extraction due to their unique and challenging characteristics. Understanding and utilizing unconventional reservoirs is crucial for meeting the world’s growing energy needs and transitioning towards a more sustainable energy future.

What Are Unconventional Reservoirs

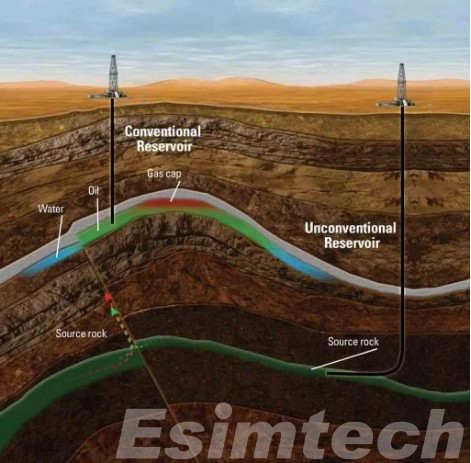

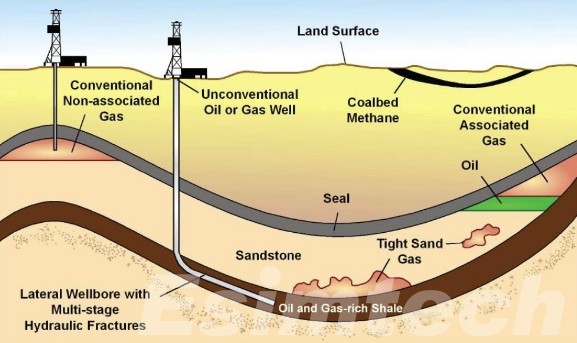

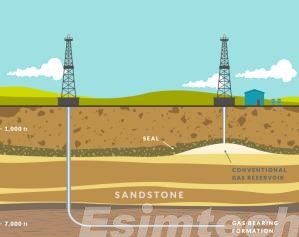

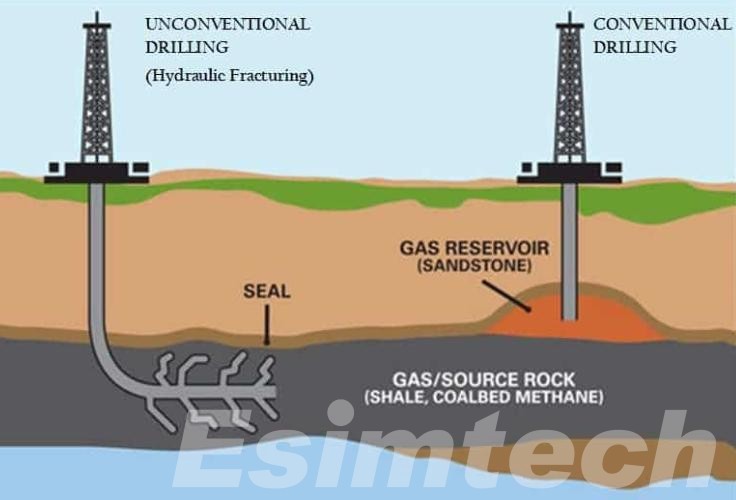

Unconventional reservoirs differ from conventional ones primarily in the nature of the rock formations that contain the hydrocarbons. In conventional reservoirs, oil and gas are typically trapped in porous and permeable rock formations like sandstone or limestone, where they can flow easily into wells. In contrast, unconventional reservoirs are characterized by low permeability and porosity, meaning the hydrocarbons are tightly bound within the rock, requiring more complex extraction methods.

Common Types of Unconventional Reservoirs

1. Shale Gas and Oil

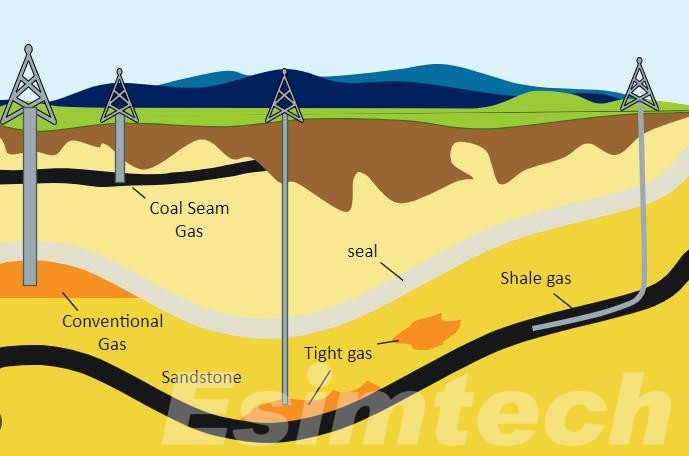

- Description: Shale formations are fine-grained sedimentary rocks that contain natural gas or oil within the microscopic pores of the rock.

- Extraction Methods: Hydraulic fracturing (fracking) and horizontal drilling are typically used to release and extract the hydrocarbons.

- Examples: Marcellus Shale, Bakken Formation, and the Eagle Ford Shale in the United States.

2. Tight Gas and Oil

- Description: Tight gas and oil are found in low-permeability rock formations, such as sandstone or limestone, where the hydrocarbons are trapped in small, hard-to-reach pores.

- Extraction Methods: Similar to shale, tight formations often require fracking and advanced drilling techniques to produce oil and gas.

- Examples: Barnett Shale, Piceance Basin, and the Wolfcamp Shale.

3. Coalbed Methane (CBM)

- Description: Coalbed methane is methane gas that is stored within coal seams. Unlike other unconventional resources, the gas is adsorbed onto the coal surface and is often accompanied by water.

- Extraction Methods: Extraction involves dewatering the coal seam to reduce pressure and release the gas.

- Examples: Powder River Basin in the U.S., Surat Basin in Australia, and Alberta’s coal fields in Canada.

4. Oil Sands (Tar Sands)

- Description: Oil sands are a mixture of sand, clay, water, and bitumen, a heavy and viscous form of crude oil. The bitumen must be separated from the sand and upgraded before it can be refined into usable fuels.

- Extraction Methods: Surface mining for shallow deposits and in-situ methods, such as steam-assisted gravity drainage (SAGD), for deeper deposits.

- Examples: Athabasca Oil Sands in Canada and the Orinoco Belt in Venezuela.

5. Gas Hydrates

- Description: Gas hydrates are crystalline structures formed from water and methane, found in deep-ocean sediments and under Arctic permafrost. They represent a massive potential energy resource, but extraction is still in the experimental stage.

- Extraction Methods: Potential methods include depressurization, thermal stimulation, or inhibitor injection to release the gas from the hydrate structure.

- Examples: Gulf of Mexico, the Arctic permafrost, and Japan’s Nankai Trough.

Key Technological Innovations in Unconventional Reservoirs

Technological advancements have been crucial in unlocking the potential of unconventional reservoirs, which are typically characterized by low permeability and challenging geological formations.

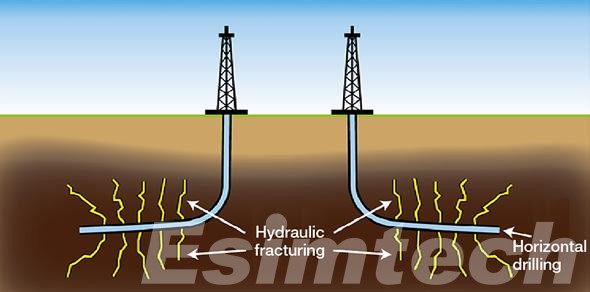

1. Horizontal Drilling

- Overview: Unlike traditional vertical wells, horizontal drilling allows for the wellbore to be extended horizontally within the target formation, often for several miles.

- Impact: This technique significantly increases the contact area with the hydrocarbon-bearing rock, enhancing the ability to extract oil and gas from low-permeability formations such as shale and tight sands.

- Application: Horizontal drilling is particularly effective in shale plays, where it is combined with hydraulic fracturing to maximize resource recovery.

2. Hydraulic Fracturing (Fracking)

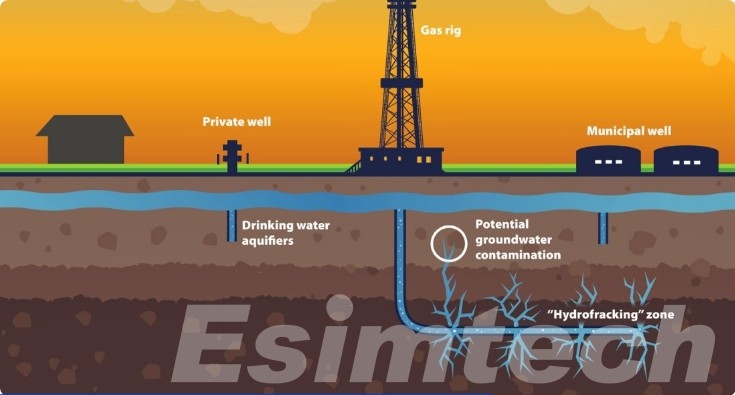

- Overview: Hydraulic fracturing involves injecting a high-pressure mixture of water, sand, and chemicals into the rock formation to create fractures, allowing hydrocarbons to flow more freely.

- Impact: Fracking has been instrumental in the shale revolution, making it economically viable to extract oil and gas from formations that were previously considered unproductive.

- Advancements: Improvements in fracking technology, such as the use of multi-stage fracking in horizontal wells, have further increased efficiency and reduced costs.

3. Enhanced Oil Recovery (EOR) Techniques

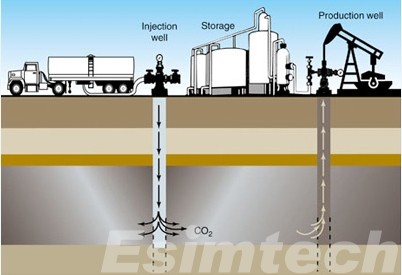

- Overview: EOR techniques are used to extract additional oil from a reservoir after primary and secondary recovery methods have been exhausted. These include thermal recovery, gas injection, and chemical flooding.

- Impact: Enhanced Oil Recovery can significantly increase the amount of oil that can be extracted from unconventional reservoirs, particularly in mature fields where conventional methods are no longer effective.

- Application: Steam-assisted gravity drainage (SAGD) is a common EOR method used in oil sands, while CO₂ injection is increasingly being used in tight oil reservoirs.

4. Microseismic Monitoring

Overview: This technology involves using sensors to monitor microseismic events, or small-scale earthquakes, that occur during hydraulic fracturing.

Impact: By providing real-time data on the size, location, and orientation of fractures, microseismic monitoring allows operators to optimize fracking operations and ensure that fractures are propagating as expected.

Application: This technique is widely used in shale gas and oil production to enhance the effectiveness of fracking and reduce environmental risks.

5. Multi-Well Pad Drilling

- Overview: Multi-well pad drilling involves drilling several wells from a single surface location, known as a pad. This reduces the environmental footprint and operational costs.

- Impact: This approach allows for the efficient development of unconventional resources, particularly in densely drilled areas like shale plays.

- Advancements: Modern rigs can drill multiple horizontal wells from a single pad, significantly reducing the time and cost associated with drilling operations.

6. Automated and Smart Drilling Technologies

- Overview: Automation and digital drilling technologies, including the use of sensors, real-time data analytics, and artificial intelligence (AI), have improved precision and efficiency.

- Impact: These technologies reduce the risk of human error, enhance safety, and optimize drilling operations, making the extraction of unconventional resources more cost-effective.

- Application: Smart drilling is increasingly being adopted in unconventional plays to reduce operational costs and improve well performance.

7. Proppant Technology

- Overview: Proppants are materials, usually sand or ceramic beads, used in hydraulic fracturing to keep the fractures open and maintain the flow of hydrocarbons.

- Impact: Advances in proppant technology, including the development of more durable and efficient proppants, have improved the effectiveness of fracking.

- Application: High-strength proppants are particularly useful in deep shale formations, where the pressure is higher.

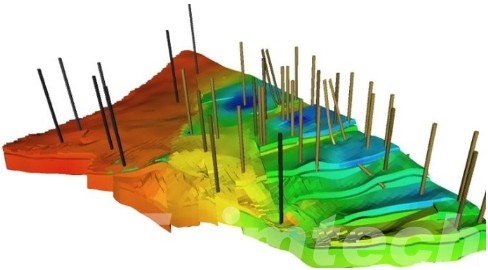

8. Advanced Reservoir Characterization

- Overview: This involves the use of sophisticated tools and techniques, such as 3D seismic imaging, well logging, and reservoir simulation, to better understand the properties and behavior of unconventional reservoirs.

- Impact: Improved reservoir characterization allows for more accurate targeting of hydrocarbon-rich zones, reducing the number of dry wells and optimizing production.

- Application: Techniques like geosteering, which uses real-time data to adjust the well trajectory, are crucial for maximizing contact with the reservoir.

9. Water Management and Recycling Technologies

- Overview: Water is a critical component in hydraulic fracturing, and managing water use and disposal is a major challenge. Innovations in water recycling and treatment technologies have improved the sustainability of unconventional resource extraction.

- Impact: These technologies reduce the environmental impact of water use in fracking and lower costs by recycling water on-site.

- Application: Closed-loop water systems and advanced filtration technologies are increasingly used in shale gas and oil operations.

10. Digital Oilfield and Data Analytics

- Overview: The digital oilfield concept involves integrating data from various sources (such as sensors, drilling equipment, and production facilities) to optimize operations.

- Impact: Real-time data analytics and machine learning algorithms can predict equipment failures, optimize production, and reduce downtime, leading to more efficient resource extraction.

- Application: Digital oilfield technologies are being used to optimize fracking schedules, monitor reservoir performance, and enhance decision-making processes in unconventional plays.

Challenges and Environmental Impact in Unconventional Reservoirs

This chart provides a concise overview of the key challenges and environmental impacts associated with the development and operation of unconventional reservoirs.

| Aspects | Challenges | Environmental Impact |

| Water Usage | High water consumption for hydraulic fracturing. | Depletion of local water resources and potential water shortages. |

| Water Contamination | Risk of groundwater contamination from fracking fluids. | Contaminated drinking water and harm to aquatic ecosystems. |

| Land Use | Extensive land requirements for drilling and infrastructure. | Habitat destruction, deforestation, and loss of biodiversity. |

| Air Quality | Emissions from drilling, fracking, and transportation. | Increased air pollution, including VOCs and particulate matter. |

| Greenhouse Gas Emissions | Methane leakage during extraction and processing. | Contribution to global warming and climate change. |

| Seismic Activity | Induced seismicity from hydraulic fracturing and wastewater disposal. | Increased risk of earthquakes and damage to infrastructure. |

| Waste Management | Disposal of large volumes of produced water and fracking fluids. | Soil contamination and potential for surface water pollution. |

| Energy Consumption | High energy requirements for extraction and processing. | Increased carbon footprint and energy inefficiency. |

| Economic Viability | High costs associated with advanced extraction technologies. | Fluctuating oil prices can impact long-term sustainability. |

The Crucial Role of Simulation Technology in the Management of Unconventional Reservoirs

Here’s chart providing a concise overview of the key simulation technologies used in unconventional reservoirs, highlighting their purpose and application in optimizing resource extraction.

| Simulation Technology | Description | Application in Unconventional Reservoirs |

| Reservoir Simulation | Numerical modeling of fluid flow, pressure, and rock-fluid interactions. | Predicts reservoir behavior, and optimizes well placement, and fracking strategies. |

| Geomechanical Simulation | Models the mechanical behavior of reservoir rock in response to operations. | Designs fracking operations assesses induced seismicity risks, and ensures safety. |

| Fracture Network Modeling | Simulates the creation and growth of fractures within the reservoir rock. | Optimizes fracking by predicting fracture size, orientation, and connectivity. |

| Fluid Flow Simulation | Models the movement of oil, gas, and water within the reservoir. | Predicts production rates, optimizes fracking stages, and manages reservoir pressure. |

| Thermal Simulation | Models heat transfer processes within the reservoir. | Optimizes steam injection in heavy oil recovery and predicts temperature changes. |

| Integrated Asset Modeling (IAM) | Combines reservoir, surface facilities, and infrastructure models. | Coordinates well operations manages flow rates, and optimizes field production. |

| History Matching | Adjusts model parameters to match historical production data. | Refines simulation models to improve accuracy and predict future performance. |

| Uncertainty Analysis | Assesses the range of possible outcomes based on varying input parameters. | Evaluates risks, predict scenarios, and aid in informed decision-making. |

| Real-Time Simulation | Continuously updates the simulation with live field data. | Monitors production, adjusts operations and manages reservoir pressure dynamically. |

| Geostatistical Simulation | Creates detailed 3D models of geological properties based on limited data. | Guides drilling, and fracking, and improves understanding of reservoir heterogeneity. |

A Trustworthy Simulation Technology Provider – Esimtech

Esimtech is a reputable provider of advanced simulation technologies, specializing in solutions for the oil and gas industry. Known for its reliability and innovation, Esimtech offers a range of simulation tools designed to enhance the exploration, drilling, and production processes, particularly in challenging unconventional reservoirs. Their products focus on improving operational efficiency, safety, and decision-making through realistic and precise modeling of subsurface conditions and reservoir behaviors. With a commitment to quality and technological advancement, Esimtech is a trusted partner for companies looking to optimize their resource extraction and management.