How Much Do You Know about Lateral Extended Reach Drilling

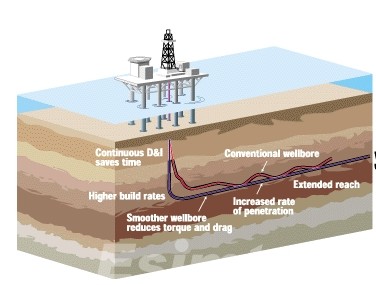

Lateral Extended Reach Drilling represents a significant advancement in the field of oil and gas exploration, allowing companies to access hydrocarbon reserves that were previously considered unreachable. Through extending the reach of horizontal wells, Lateral Extended Reach Drilling enables the exploitation of resources located far from the drilling pad, enhancing the efficiency and sustainability of oil and gas production.

What is Lateral Extended Reach Drilling

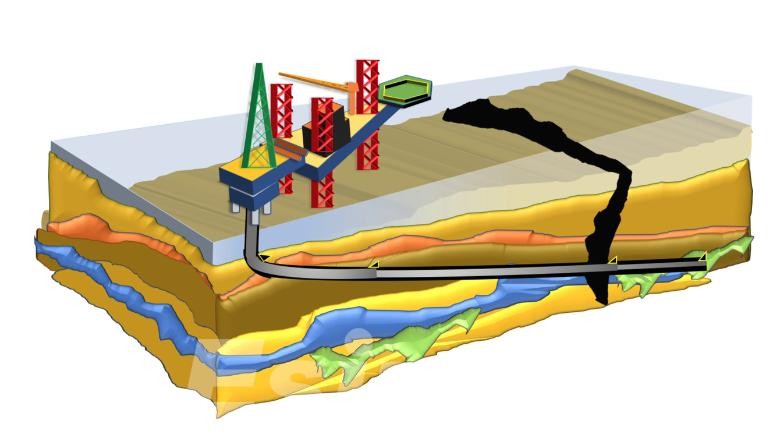

Lateral Extended Reach Drilling is a technique used in the oil and gas industry to drill wells with extended horizontal sections, often exceeding several kilometers in length. This approach maximizes the contact between the wellbore and the hydrocarbon-bearing formation, thereby increasing the production potential of a single well. Lateral Extended Reach Drilling is particularly valuable in offshore and environmentally sensitive areas, where minimizing surface disturbance is crucial.

The Technology Behind Lateral Extended Reach Drilling

The success of Lateral Extended Reach Drilling relies on a combination of advanced technologies, precision engineering, and real-time data management.

1. Rotary Steerable Systems (RSS)

Rotary Steerable Systems are the backbone of Extended Reach Drilling, allowing for precise control over the wellbore trajectory. Unlike traditional systems where the entire drill string must be rotated to change direction, RSS can adjust the drill bit’s path without altering the rotation of the drill string. This results in smoother wellbores, reduced friction, and the ability to navigate complex geological formations with high accuracy.

2. Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD) Technologies

Measurement While Drilling and Logging While Drilling tools are essential for real-time data acquisition during the drilling process. MWD systems provide critical information about the well’s inclination, azimuth, and tool face, enabling precise directional control. LWD tools, on the other hand, collect data on the formation’s properties, such as porosity, density, and fluid content. This information is crucial for making on-the-fly decisions, ensuring that the well remains on target and maximizes reservoir contact.

3. High-Strength Drill Pipes

The extended lateral lengths in Lateral Extended Reach Drilling demand drill pipes that can withstand extreme mechanical stresses. High-strength drill pipes, often made from advanced alloys, are engineered to endure the high torque, tension, and pressure encountered in extended reach wells. These pipes are also designed to be lightweight, reducing the overall load on the drilling rig and improving operational efficiency.

4. Advanced Mud Systems

Drilling fluid, or mud, plays a critical role in Lateral Extended Reach Drilling operations. It helps to lubricate the drill bit, stabilize the wellbore, and carry cuttings to the surface. In Lateral Extended Reach Drilling, the mud system must be tailored to minimize friction and prevent wellbore collapse over the long horizontal sections. This often involves the use of synthetic or oil-based muds, which provide superior lubrication and stability compared to traditional water-based muds.

5. Wellbore Stability and Pressure Management

Maintaining wellbore stability is crucial in ERD drilling, especially as the well extends further from the drilling pad. Technologies like Managed Pressure Drilling (MPD) help control downhole pressures, preventing issues such as blowouts or wellbore collapse. MPD systems continuously monitor and adjust the pressure profile within the well, ensuring safe and stable drilling conditions.

6. Downhole Motors and Turbodrills

In some cases, downhole motors or turbodrills are employed to provide additional power and control during the drilling process. These devices are placed near the drill bit and use the flow of drilling fluid to generate rotational force, enhancing the ability to steer the wellbore and maintain the desired trajectory.

7. Real-Time Data Analytics and Automation

The integration of real-time data analytics and automation is a game-changer for Lateral Extended Reach Drilling. Advanced software platforms analyze data from MWD, LWD, and other sensors to optimize drilling parameters in real-time. Automation systems can adjust drilling speed, torque, and pressure based on this data, improving accuracy and reducing the risk of human error.

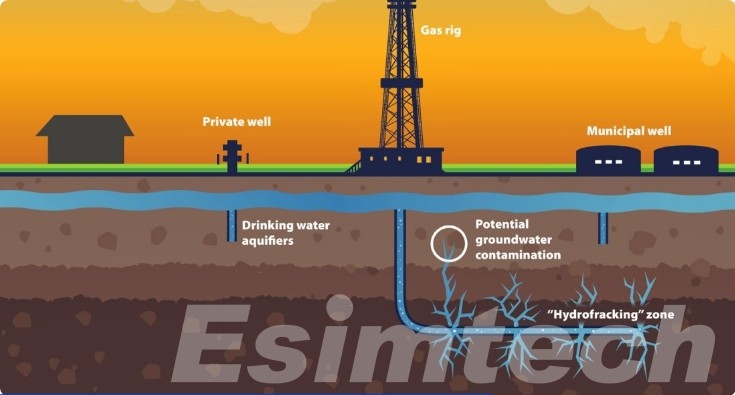

8. Hydraulic Fracturing Technology

In unconventional reservoirs, hydraulic fracturing is often used in conjunction with Extended Reach Drilling to enhance production. This process involves injecting high-pressure fluid into the wellbore to create fractures in the surrounding rock, increasing the flow of hydrocarbons. Innovations in fracturing techniques and materials have significantly improved the efficiency and effectiveness of this process in Lateral Extended Reach Drilling applications.

9. Extended Reach Well Planning Software

Effective planning is critical for the success of Lateral Extended Reach Drilling operations. Advanced well planning software allows engineers to model the well trajectory, simulate drilling conditions, and anticipate potential challenges before drilling begins. These tools help in designing the most efficient well path, optimizing resource recovery, and minimizing operational risks.

10. Integrated Drilling Rigs

Lateral Extended Reach Drilling requires drilling rigs that are capable of handling the unique demands of extended reach operations. These rigs are equipped with powerful hoisting systems, top drives, and advanced control systems that ensure precise handling of the drill string and other equipment. The integration of all these systems on the rig floor enhances the overall efficiency and safety of the drilling operation.

Applications of Lateral Extended Reach Drilling

| Application Area | Description |

| Offshore Oil and Gas Exploration | Accesses distant reservoirs from a single offshore platform, reducing the need for multiple platforms and minimizing environmental impact. |

| Unconventional Resource Development | Extracts hydrocarbons from shale, tight gas, and coalbed methane formations increasing contact with the reservoir and enhancing production rates. |

| Extended Reservoir Coverage | Maximizes wellbore exposure to thin or scattered reservoirs, enabling more efficient recovery of hydrocarbons with fewer wells. |

| Multilateral Wells | Drills multiple lateral branches from a single wellbore, increasing reservoir contact and optimizing resource extraction from complex reservoirs. |

| Brownfield Redevelopment | Reaches untapped areas of existing fields, extending the life of mature oil and gas fields and improving recovery rates. |

| Environmental and Cost Efficiency | Reduces surface footprint and environmental impact by drilling multiple extended reach wells from a single location, optimizing resource management. |

| Deepwater Operations | Enables the development of deepwater reservoirs by drilling long horizontal sections, allowing for efficient resource extraction in challenging environments. |

| Subsea Production | Connects multiple subsea production points to a single platform or wellhead, simplifying infrastructure and reducing operational costs. |

| Geothermal Energy Extraction | Accesses deep geothermal reservoirs, improving the efficiency of heat extraction and enhancing the viability of geothermal energy projects. |

Challenges and Future Directions in Lateral Extended Reach Drilling

Challenges

1. Technical Complexity

- Description: Drilling long, extended laterals requires advanced technology and precise control. Maintaining wellbore stability over long distances is challenging due to the risk of tool deviation and formation instability.

- Impact: Increased risk of wellbore collapse or deviation, which can lead to costly remediation or abandonment.

2. High Costs

- Description: The technology and equipment required for extended-reach drilling are expensive. This includes advanced drilling rigs, specialized tools, and enhanced logging and monitoring systems.

- Impact: High initial investment and operational costs, can affect project economics, especially in low-margin environments.

3. Formation Pressure and Temperature

- Description: Extended reach wells often encounter extreme pressures and temperatures, which can impact equipment performance and drilling fluid behavior.

- Impact: Increased risk of equipment failure and operational challenges in managing wellbore conditions.

4. Data Acquisition and Interpretation

- Description: Gathering and interpreting data from extended reach wells is complex due to the length and depth of the wellbore. Accurate real-time data is crucial for making informed decisions during drilling.

- Impact: Difficulty in monitoring well conditions and making adjustments in real-time, leading to potential inefficiencies or drilling hazards.

5. Environmental and Safety Concerns

- Description: Extended reach drilling can have significant environmental and safety implications, including risks associated with blowouts or spills, especially in sensitive areas.

- Impact: Increased regulatory scrutiny and potential for environmental incidents, requiring rigorous safety protocols and environmental management.

Future Directions

1. Advancements in Drilling Technology

- Description: Development of more robust and precise drilling tools and technologies, such as improved drill bits, advanced telemetry systems, and real-time data analytics.

- Goal: Enhance drilling accuracy and efficiency, reduce costs, and improve safety and environmental performance.

2. Enhanced Real-Time Monitoring

- Description: Integration of advanced sensors, machine learning algorithms, and real-time data analytics to improve monitoring and control of extended reach wells.

- Goal: Provide better insights into well conditions, allowing for proactive management and quicker response to potential issues.

3. Improved Drilling Fluids

- Description: Research and development of new drilling fluids that can withstand extreme pressures and temperatures while maintaining wellbore stability.

- Goal: Enhance the performance and reliability of drilling operations in challenging conditions.

4. Sustainable Practices

- Description: Focus on minimizing the environmental impact of extended reach drilling through better waste management, reduced surface footprint, and enhanced safety measures.

- Goal: Align with global sustainability goals and regulatory requirements, reducing the ecological impact of drilling activities.

5. Cost Reduction Strategies

- Description: Implementation of cost-saving technologies and processes, such as modular rigs, improved logistics, and streamlined operations.

- Goal: Lower the overall cost of extended reach drilling, making it more economically viable for a wider range of projects.

6. Collaboration and Innovation

- Description: Foster collaboration between industry stakeholders, technology providers, and research institutions to drive innovation and address common challenges.

- Goal: Accelerate the development of new solutions and best practices in extended reach drilling.

How Simulations are Used in Lateral Extended Reach Drilling

This chart provides a clear overview of how simulations contribute to various aspects of lateral extended reach drilling, helping to optimize operations and ensure successful outcomes.

| Application | Purpose | How It’s Done |

| Wellbore Trajectory Planning | Plan the wellbore path to reach the target efficiently. | Model different drilling paths, including horizontal and inclined sections. |

| Drilling Dynamics Analysis | Manage forces and interactions between drill bit and formation. | Simulate bit-rock interactions and predict issues like stick-slip and vibrations. |

| Formation Evaluation | Assess formation characteristics impacting drilling decisions. | Model pressure, temperature, and rock strength for optimized drilling. |

| Real-Time Monitoring and Adjustment | Adjust drilling parameters in real time. | Real-time drilling simulations are used to predict and correct deviations. |

| Drilling Fluid Optimization | Select and manage effective drilling fluids. | Simulate fluid behavior under varying conditions for optimal performance. |

| Risk Assessment and Management | Identify and mitigate potential drilling risks. | Evaluate scenarios like blowouts and wellbore instability to develop contingency plans. |

| Equipment Performance Evaluation | Assess the performance and reliability of drilling equipment. | Simulate equipment performance to ensure it withstands extended reach conditions. |

| Cost Estimation and Resource Management | Estimate costs and optimize resource allocation. | Simulate different scenarios to manage budgeting and resource use. |

| Training and Skill Development | Train personnel in handling complex drilling scenarios. | Use simulation-based training programs for skill enhancement. |

| Collaboration and Communication | Improve coordination among team members and stakeholders. | Provide a shared platform for visualizing and discussing drilling plans. |

As the demand for energy continues to grow, Lateral Extended Reach Drilling will play a critical role in meeting global energy needs while adhering to stricter environmental standards and represents the future of efficient, responsible resource extraction.