How Much do You Know about Arctic Drilling

Arctic drilling refers to the exploration and extraction of oil and natural gas resources in the Arctic region which is known for its vast and largely untapped fossil fuel reserves. As global energy demands increase and traditional oil fields deplete, the Arctic has become a focal point for energy companies seeking new sources of oil and gas. However, extreme environmental conditions, logistical challenges, and environmental concerns make Arctic drilling become one of the most complex and debated activities in the energy sector.

The Importance of Arctic Drilling

The Arctic is believed to hold significant reserves of untapped oil and gas. It is estimated that the region contains around 13% of the world’s undiscovered oil and 30% of its untapped natural gas. For energy companies, this makes Arctic drilling an attractive prospect, offering access to some of the last remaining large-scale reserves on Earth.

In addition to the potential economic benefits, Arctic drilling also plays a strategic role in ensuring global energy security. As countries continue to look for ways to diversify their energy sources, the Arctic’s vast untapped resources become more valuable. For Arctic nations like Russia, Canada, and the United States, the ability to harness these resources could be key to economic growth and energy independence.

Challenges of Arctic Drilling

1. Extreme Environmental Conditions

One of the most significant challenges of Arctic drilling is the region’s extreme environment. Temperatures in the Arctic can drop as low as -40°C (-40°F), and the region experiences long periods of darkness during the winter months. These conditions not only pose risks to drilling equipment, which can freeze and malfunction but also create dangerous working conditions for crews. The thick ice cover and unpredictable weather patterns make transportation of personnel, equipment, and supplies extremely difficult, increasing operational costs.

Additionally, the region’s fragile ecosystems, which include rare wildlife and pristine natural landscapes, make drilling operations highly risky. A spill or accident could have catastrophic long-term consequences for both the environment and the people who depend on it.

2. Logistical and Infrastructure Challenges

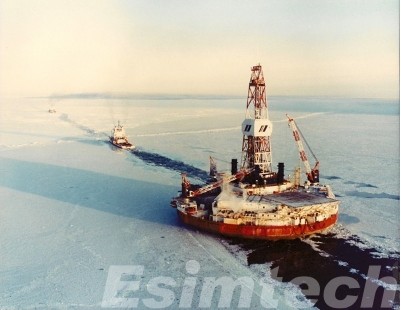

The Arctic’s remoteness means that establishing the infrastructure required for drilling operations is both expensive and time-consuming. Specialized drilling rigs must be equipped to deal with the unique conditions of the region, including shifting sea ice and icebergs. Transporting equipment to the drilling site is an enormous logistical challenge, as there are few existing roads or ports in the area. The distance from shore also complicates emergency response efforts—if something goes wrong, it may take days or even weeks to deploy help.

Moreover, the lack of sufficient infrastructure makes it harder to manage the waste products generated by drilling, such as wastewater, chemicals, and debris. Managing these byproducts safely and responsibly is critical to minimizing environmental damage.

3. Environmental Risks

One of the most concerning aspects of Arctic drilling is the risk of oil spills. In colder temperatures, oil does not break down as quickly, and ice-covered waters make spill containment and cleanup much more difficult. In the event of a spill, the icy conditions limit the ability to deploy response teams and equipment, making the risk of a prolonged environmental disaster high.

Additionally, the construction and operation of drilling rigs and other infrastructure can have significant negative impacts on the region’s sensitive wildlife. Marine mammals like polar bears, seals, and whales, as well as migratory birds, rely on the Arctic’s ecosystems for food and shelter. Any disruption to these habitats—whether from drilling noise, oil spills, or increased human presence—can have long-lasting effects on the region’s biodiversity.

Technological Innovations in Arctic Drilling

Despite these challenges, significant technological advancements have been made to make Arctic drilling more feasible and safer. Modern drilling rigs are designed to withstand extreme conditions, with ice-resistant hulls, specialized coatings to prevent freezing, and advanced blowout preventers (BOPs) that help control well pressure.

1. Ice-resistant Drilling Rigs

These rigs are specifically engineered to withstand the movement of sea ice, extreme cold temperatures, and high winds that are characteristic of Arctic environments. By incorporating reinforced structures and flexible platforms, these rigs can remain operational throughout the year, even in shifting ice conditions. This technological advancement significantly reduces the risk of accidents caused by ice impact and allows for year-round drilling operations, which were once limited to shorter, warmer months.

2. Extended Reach Drilling (ERD)

ERD drilling allows operators to drill wells from a central location, reaching distances far beyond what was previously possible. This technology eliminates the need for multiple drilling sites, minimizing the surface impact on the sensitive Arctic environment. Drilling from a single location, not only reduces the logistical burden of transporting equipment and personnel but also improves efficiency and reduces costs.

3. Remote-controlled and Automated Systems

These remote drilling systems allow operators to control drilling operations from safe distances, either from onshore control rooms or from offshore platforms far removed from the drilling sites. Automation and robotics play a crucial role in reducing human exposure to harsh conditions, as well as improving accuracy and operational efficiency. These technologies can carry out complex tasks like well monitoring, maintenance, and real-time decision-making, ensuring that drilling operations proceed smoothly without compromising safety.

4. Innovations in Spill Prevention and Response Technologies

These technologies are central to minimizing the environmental risks associated with Arctic drilling. Advanced blowout preventers (BOPs), designed to seal off a well in case of an emergency, have been enhanced to operate in the extreme cold. The use of real-time monitoring systems and advanced subsea technologies also ensures that any potential issues are detected and addressed immediately, reducing the likelihood of spills. The development of better containment devices and techniques tailored for ice-covered waters has significantly improved the ability to respond to accidents, should they occur, although the region still presents inherent challenges for spill cleanup.

5. Environmentally Friendly Drilling Fluids

These biodegradable fluids are designed to function in extreme cold without harming marine ecosystems. Additionally, innovations in waste management systems ensure that drilling byproducts are properly treated and disposed of, minimizing pollution risks.

How Simulation Technologies are Used to Optimize Arctic Drilling

This chart summarizes the various ways simulation technologies enhance Arctic drilling by predicting environmental impacts, optimizing operations, improving safety, and supporting decision-making processes.

| Application Area | Use of Simulation Technologies |

| Environmental Impact Prediction | – Models oil spill behavior in cold waters. – Simulates ice movement and interactions with equipment. – Predicts dispersion and emulsification of pollutants in icy conditions. |

| Drilling Operations & Well Control | – Drilling simulators can model working processes and equipment behavior under extreme conditions. – Predicts wellbore stability, cementing, and pressure management. – Use Blowout Preventer (BOP) simulators to train for emergency situations. |

| Ice & Structural Engineering | – Models ice floe behavior and its impact on platforms. – Assesses structural response to ice-induced forces. – Simulates interaction between ice and drilling rigs for structural stability. |

| Remote Operations & Automation | – Develops autonomous drilling and control systems for remote operation. – Simulates real-time data flow and adjusts control systems accordingly. – Reduces the need for on-site personnel by improving remote monitoring. |

| Safety & Emergency Response | – Simulates emergency scenarios like blowouts or spills. – Trains personnel on response protocols and crisis management. – Models spill response and containment strategies in Arctic environments. |

| Subsea & Seafloor Simulations | – Simulates seafloor stability and well integrity under Arctic conditions. – Assesses subsea equipment behavior in icy waters. – Provides data for optimal drilling site selection and risk assessment. |

| Resource Estimation & Economics | – Models oil and gas reservoir conditions, extraction rates, and economic feasibility. – Predicts long-term productivity and potential yields of Arctic wells. – Helps in cost-benefit analysis and financial planning for drilling projects. |

Ethical and Environmental Considerations in Arctic Drilling

The ethics of Arctic drilling are contentious. While energy companies and governments may point to the economic benefits and energy security provided by Arctic drilling, there are significant concerns about its environmental impact.

The Arctic is a fragile and ecologically sensitive region, and many argue that the risks of drilling—such as oil spills, habitat destruction, and the potential contribution to climate change—outweigh the benefits. Indigenous communities, many of whom rely on the region’s natural resources for their livelihoods, have also voiced opposition to drilling in the Arctic. These communities argue that industrial development could disrupt traditional hunting and fishing practices and cause long-lasting harm to their way of life.

The broader environmental concern is that drilling in the Arctic will further contribute to global climate change. The extraction and burning of fossil fuels continue to drive the emissions of greenhouse gases, and the region’s melting ice due to climate change may accelerate the release of additional carbon stored in Arctic permafrost. The opening up of Arctic oil fields could have profound long-term consequences for the planet’s climate.

Wrap Up

Arctic drilling presents both opportunities and challenges. While it holds significant energy potential, extreme conditions, logistical difficulties, and environmental concerns make it a complex and controversial issue. With continued innovation and a growing focus on sustainability, the future of Arctic drilling will depend on balancing energy needs with environmental responsibility.