How Managed Pressure Drilling is Revolutionizing Traditional Drilling Methods

Managed Pressure Drilling (MPD) has evolved as a novel way to oil and gas exploration, revolutionizing traditional drilling methods. This innovative drilling techniques provides dynamic control over wellbore pressure, reducing the risks associated with wellbore instability, fluid management, and safety concerns. In this article, we delve into the principles, applications, and benefits of Managed Pressure Drilling, highlighting its pivotal role in the ever-evolving landscape of hydrocarbon extraction and how simulation technology is employed in Managed Pressure Drilling to enhance its success and efficiency.

Understanding Managed Pressure Drilling

Managed Pressure Drilling is an advanced drilling technique that involves continuously monitoring and controlling wellbore pressure throughout the drilling operation. Unlike traditional drilling methods, MPD allows for real-time modifications to drilling parameters, which optimizes wellbore pressure and improves drilling performance. The fundamental goals of MPD are to preserve wellbore stability, reduce drilling fluid losses, and prevent blowouts.

Key Components of Managed Pressure Drilling System

1. MPD Control System

The control system is at the heart of an MPD drilling system, as it integrates different sensors and equipment to continuously monitor downhole conditions. This real-time data is then used to make immediate changes to drilling parameters including mud weight, flow rates, and choke settings.

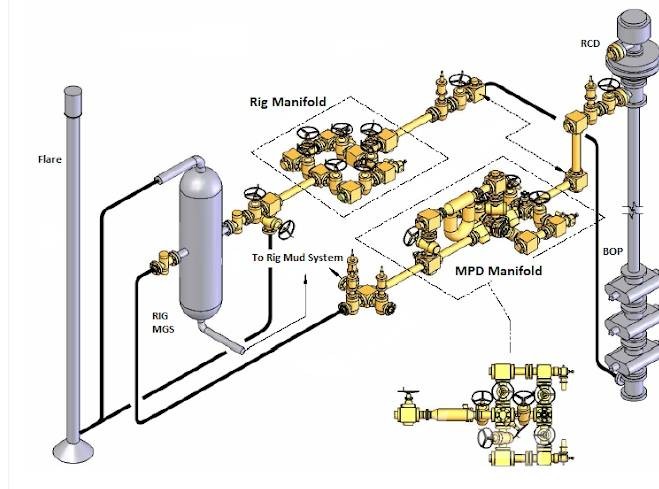

2. Choke Manifold

The choke manifold is an important component that enables for precise regulation of pressure in the wellbore. It is made up of a series of valves and chokes that control the flow of drilling fluid, thereby maintaining the desired pressure within the wellbore.

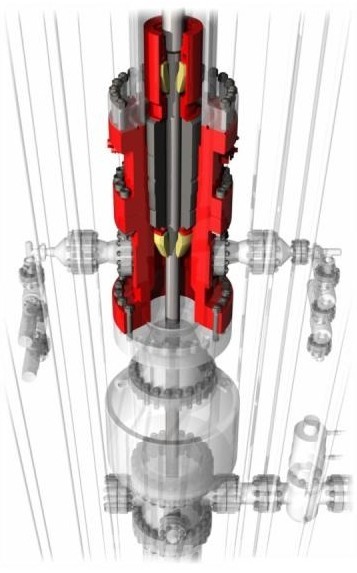

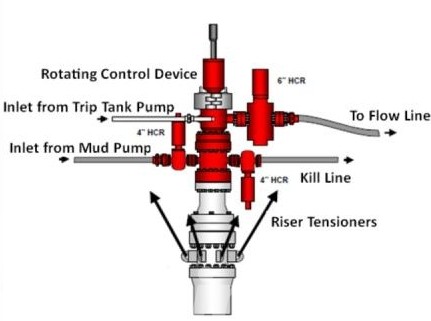

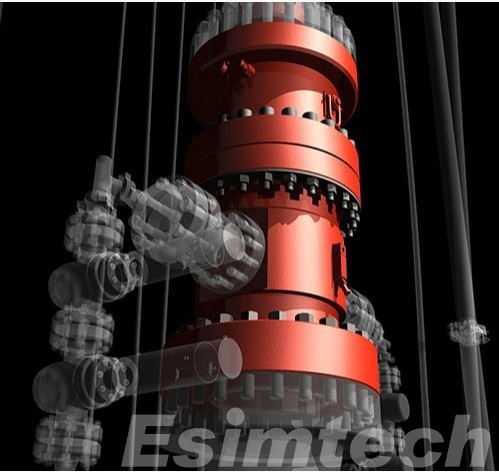

3. Rotating Control Device (RCD)

4. MPD Equipment

Various types of managed pressure drilling equipment, including specialized drilling rigs, pumps, and sensors, are employed to create a comprehensive MPD system. These components work in tandem to optimize drilling parameters based on real-time data feedback.

Benefits of Managed Pressure Drilling

| Benefit | Description |

| Wellbore Stability | Maintains wellbore pressure to prevent fluid influx and wellbore instability. |

| Kick and Loss Control | Allows real-time control of kicks and losses, enhancing well control. |

| Enhanced Safety | Minimizes the risk of well control incidents and blowouts. |

| Extended Drilling Windows | Enables drilling in narrow pressure margins and challenging formations. |

| Improved Rate of Penetration | Optimizes drilling efficiency, leading to faster rates of penetration. |

| Reduced Non-Productive Time | Minimizes downtime associated with well control issues. |

| Reservoir Protection | Helps protect the reservoir by avoiding fluid invasion. |

| Compatibility with Various Fluids | Adaptable to different drilling fluids and well conditions. |

| Enhanced Drilling Economics | Potential cost savings through improved efficiency and reduced risks. |

| Flexibility in Operations | Suitable for various drilling environments and well types. |

Applications of Managed Pressure Drilling

| Application | Description |

| Onshore Drilling | Utilized in conventional and unconventional onshore drilling operations. |

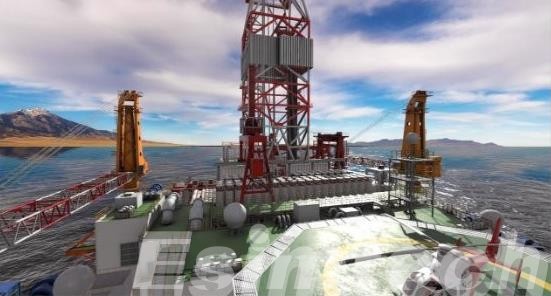

| Offshore Drilling | Particularly beneficial in deepwater and challenging offshore environments. |

| Drilling in Narrow Pressure Windows | Well-suited for drilling in formations with tight pressure margins. |

| Extended Reach Drilling | Facilitates drilling in extended reach wells with varying pressure conditions. |

| High-Pressure High-Temperature Wells (HPHT) | Effective in drilling wells with extreme pressure and temperature conditions. |

| Managed Pressure Cementing | Enhances control during cementing operations, reducing the risk of lost circulation. |

| Underbalanced Drilling (UBD) | Can be applied for underbalanced drilling operations, minimizing formation damage. |

| Geothermal Drilling | Useful in geothermal drilling projects, ensuring efficient and safe operations. |

| Coalbed Methane Drilling | Applied in drilling for coalbed methane, optimizing gas extraction. |

| Managed Pressure Drilling Workovers | Utilized during workovers to control pressures and enhance safety. |

| Extended Well Testing (EWT) | Applied during extended well testing to manage pressures and collect data. |

| Drilling through Fault Zones | Facilitates drilling through faulted formations, maintaining pressure control. |

Simulation Technology Used in Managed Pressure Drilling

1. Dynamic Wellbore Modeling

Oil and gas simulation software enables the production of dynamic wellbore models that take into account a variety of elements, including formation characteristics, wellbore geometry, and drilling fluid properties. These models may replicate the behavior of the wellbore under various situations, revealing potential obstacles and enabling the development of appropriate drilling tactics.

2. Pressure Control Simulations

Simulation technology offers real-time simulation of pressure control scenarios. This includes analyzing choke settings, drilling fluid circulation rates, and other parameters to ensure that wellbore pressure remains within the intended range. Simulations assist in identifying potential pressure-related difficulties and optimizing control measures to prevent kicks or blowouts.

3. Kick and Loss Detection Simulations

Advanced simulation tools can replicate scenarios where kicks or fluid losses may occur. By inputting various conditions into the simulation, drilling teams can assess the effectiveness of kick detection systems and develop strategies for mitigating and managing kicks promptly. This proactive approach enhances well control and overall safety.

4. Choke Management Optimization

Simulations assist in optimizing choke management strategies. Engineers can model different choke settings and configurations to determine the most effective approach for maintaining wellbore pressure. This ensures that the choke manifold is operated efficiently, minimizing the risk of pressure-related issues during drilling.

5. Real-time Decision Support Systems

Simulation technology can be integrated into real-time decision support systems. These systems use data from the drilling operation to continuously update the simulation model, providing instant feedback and recommendations to drilling personnel. Real-time simulations enhance the ability to respond rapidly to changing downhole conditions.

6. Training Simulators

Virtual drilling simulators are effective instruments for teaching drilling crews MPD methods. These simulators imitate the drilling environment, allowing operators to practice various scenarios and perfect their abilities in a safe virtual context. Training simulators contribute to improved competency among drilling personnel, enhancing overall operational safety.

7. Geological and Reservoir Modeling

Simulation technology extends to geology and reservoir modeling, allowing engineers to gain a better understanding of underlying conditions. By combining geological data and drilling models, teams can anticipate formation changes, pore pressure variations, and other geological phenomena that may affect drilling operations.

8. Data Analysis and Post-Drill Evaluation

After drilling operations are completed, simulation technology helps with post-drill evaluations. Engineers can study actual drilling data and compare it to hypothetical scenarios. This retrospective analysis helps to discover areas for improvement, adjust simulation models, and increase future prediction accuracy.

Conclusion

Managed Pressure Drilling is at the cutting edge of technological innovation in the oil and gas sector, providing a dynamic and controlled approach to drilling operations. MPD drilling is an important part of current drilling methods because of its capacity to improve safety, maximize efficiency, and solve difficult downhole circumstances.

Simulation technology is a critical enabler for implementing Managed Pressure Drilling. It offers a virtual platform for testing, optimization, and training, resulting in safer and more efficient drilling operations. As technology advances, the integration of simulation tools with real-time monitoring and control systems will become increasingly important for the success of Managed Pressure Drilling projects.