How Intelligent Well Completion Reduces Environmental Impact

Oil and gas industry environmental footprint has long been the subject of scrutiny, yet technological innovations are leading the way towards more eco-friendly practices. One such innovation is intelligent well completion – an advanced strategy which not only increases operational efficiency but also significantly decreases environmental impact. This article investigates how intelligent well completion addresses key environmental challenges while contributing towards creating a more sustainable future.

Understanding Intelligent Well Completion

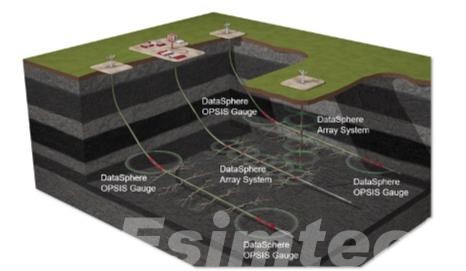

Intelligent well completion is a contemporary approach to well completion that incorporates advanced technologies to maximize production, improve reservoir management and minimize environmental impact. While traditional methods rely on static systems and manual interventions for completion of wells, intelligent well completion utilizes tools such as sensors, automation and data analytics for real-time monitoring and control allowing operators to monitor pressure, temperature and flow rates in real time so as to maximize efficiency while decreasing waste.

Intelligent well completion employs advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and automated controls to ensure wells run at peak performance while meeting environmental concerns. Not only can intelligent well completion improve resource recovery; its dynamic approach also plays an integral part in reducing emissions, conserving water usage, and preventing spills – making it essential to sustainable oil and gas operations.

Key Environmental Challenges in Oil and Gas

Oil and gas industries operate within an extremely complex environment where balancing production with environmental protection are central factors of success. Some of the key environmental challenges facing them today include:

- Methane Emissions: Methane emissions, an extremely potent greenhouse gas far more potent than carbon dioxide, are frequently released during drilling, production and transport activities. Unintentional leakage through unintended leakages known as “fugitive emissions” further compounds climate change effects.

- Consumption and Contamination: Oil and gas operations requiring hydraulic fracturing require large volumes of water for their operations, with improper management leading to local supplies becoming depleted as chemical spills or improper wastewater disposal occur and pollute the groundwater supply.

- Energy Intensity: Oil and gas exploration, processing and transport all require significant energy consumption; their dependence on fossil fuels to operate contributes significantly to climate change through carbon emission production cycles that only exacerbate its severity.

- Land Disruption and Habitat Loss: Drilling activities often necessitate extensive land usage, leading to deforestation, habitat destruction and soil erosion. Construction of access roads, pipelines and drilling pads often fragment ecosystems while disrupting wildlife populations.

- Risks Presented by Oil Spills and Chemical Leaks: Accidental spills during drilling, transportation or storage operations can have severe repercussions for marine and terrestrial ecosystems alike; oil spills in particular pose lasting threats to aquatic life, coastal environments and local communities.

- Waste Generation: Oil and gas operations generate large volumes of waste material such as drilling muds, cuttings, and produced water that must be safely disposed of to avoid soil and water pollution. If improper disposal practices are implemented for these materials it could contribute to soil and water pollution issues.

Addressing these challenges demands innovative solutions, and intelligent well completion has emerged as a promising technology that helps limit environmental risks while still producing energy efficiently.

How Intelligent Well Completion Reduces Environmental Impact

Intelligent well completion is revolutionizing the oil and gas industry by solving environmental challenges head on. Utilizing cutting edge technologies, this approach not only increases operational efficiency but also significantly decreases environmental footprint of operations. Below are three ways intelligent well completion contributes to environmental sustainability:

Minimizing Methane Emissions

Drilling and production processes release large volumes of methane emissions that contribute significantly to climate change. Intelligent well completion systems use real-time monitoring tools and automated controls to quickly detect leaks quickly, helping operators locate them before they escalate further and seal leaks before climate change worsens further. By taking such proactive action against methane emission sources, operators can dramatically lower methane emissions thus helping fight global climate change more effectively.

Optimizing Water Usage

Water is an integral component of oil and gas operations, especially hydraulic fracturing, so intelligent well completion systems must ensure only necessary amounts of water are being consumed, thus limiting waste while relieving strain on local supplies. Furthermore, advanced filtering technologies and recycling programs may further promote conservation measures.

Enhancing Energy Efficiency

Intelligent well completion technologies such as downhole sensors and automated valves enable precise control over production processes, by optimizing flow rates, pressure, and temperature to reduce energy use for extraction, transportation, processing and treatment – not only decreasing operational costs but also contributing to global efforts of decreasing greenhouse gas emissions.

Reducing Surface Footprint

Traditional drilling operations often necessitate extensive infrastructure, disrupting habitat and leading to land degradation. Intelligent well completion solutions include multilateral drilling and extended reach wells which access multiple reservoirs from one wellbore. This reduces surface footprint as more reservoirs can be reached through one bore. Furthermore, compact modular designs of intelligent completion equipment further diminish their environmental footprint.

Improving Spill Prevention

Oil spills pose significant threats to ecosystems and communities alike, but intelligent well completion systems help mitigate those risks by providing real-time data about well integrity, pressure and flow rates – as well as automated shut-off valves which respond instantly when anomalies appear – thus helping avoid spills altogether. Furthermore, predictive analytics powered by AI enable operators to identify potential failure points that require action from them and thus warding off environmental disaster.

Intelligent well completion not only increases operational efficiency but also aligns oil and gas industry sustainability goals with global goals for reduced environmental impact while meeting world energy demands. This innovative method shows how technology can be harnessed to make an impactful contribution toward this effort.

The Role of Technology in Enhancing Sustainability

The efficiency for intelligent completion of wells in cutting down environmental impacts is rooted in the incorporation of the most advanced technologies. These advancements allow for more efficient, smarter environmentally-friendly processes. Below are the major technological advances that are promoting sustainability in the energy and oil industry:

IoT and Sensors

The Internet of Things (IoT) and the latest sensor technology are at the core intelligence in well completion. These devices provide real-time monitoring of vital parameters, such as pressure, temperature flows, temperature and the performance of equipment. Through the continuous collection and transmission of data, IoT enabled sensors allow operators to identify abnormalities, improve production processes, and avoid environmental risks. This constant monitoring helps ensure that wells are operating at maximum efficiency while minimizing emission and waste.

Automation

Automation is changing the way wells are completed by reducing the need for manual intervention, and increasing efficiency. Automated systems regulate valves, alter the rate of production, as well as operate equipment for downholes with unmatched accuracy. This is not just more efficient but also decreases the chance of human error that could result in environmental hazards. For instance automatic shut-off valves are able to immediately respond to changes in pressure or leaks, thus avoiding methane emission and minimizing spills. Automated operations make sure that they are more secure and environmentally sustainable.

AI and Machine Learning

Artificial Intelligence (AI) as well as machine-learning are revolutionizing the way the business analyzes and uses data. These systems process huge amounts of data generated by sensors as well as other data sources. They discover patterns, anticipate equipment failures and optimize production strategies. For example, AI algorithms can forecast reservoir behavior, allowing operators to alter extraction techniques to decrease the use of water or energy. With actionable information, AI and machine learning assist operators in making better environmental choices.

These technologies are working together to help create an environmentally sustainable oil and gas business. As these technologies continue to advance their contribution to sustainability will only increase and help the industry achieve its environmental targets while maintaining efficiency.

Intelligent well completion can be described as an exciting change in the field of oil and gas that can lead to more environmentally sustainable operations. By reducing methane emissions and optimizing water use, increasing the efficiency of energy, reducing surface footprint, and improving the ability to prevent spills This technology can address one of the greatest environmental problems. As the advancements in IoT automation, AI continues to advance smart ways of completing wells are likely to play a crucial role in reducing the environmental impacts of gas and oil production.