How Geomechanics Applied in Reservoir Engineering to Optimize Hydrocarbon Recovery

In reservoir engineering, understanding the physical properties and mechanical behavior of subsurface formations is crucial for optimizing oil and gas production. Geomechanics, the study of how geological formations respond to stresses, pressures, and deformations, has become a vital discipline in reservoir engineering. By applying geomechanical principles, engineers can gain insights into how rocks and fluids interact under various stress conditions, enhancing both the safety and efficiency of extraction processes.

Key Components of Geomechanical Modeling in Reservoir Engineering

The key components of geomechanical modeling in reservoir engineering include several interconnected parameters and data that define the behavior of geological formations under stress.

1. Stress Field

- In-Situ Stresses: Includes vertical (overburden) and horizontal stresses that influence the reservoir’s response to production activities.

- Stress Orientation and Magnitude: Understanding the direction and strength of stress in a reservoir helps in predicting fracture behavior, optimal wellbore orientation, and potential stability issues.

2. Rock Properties

- Elastic Properties: Young’s modulus and Poisson’s ratio, which measure rock stiffness and deformation, respectively, determine how rocks will respond to stress changes.

- Strength Properties: Cohesion, internal friction angle, and tensile strength are key for assessing rock failure potential, impacting wellbore stability and hydraulic fracturing.

- Porosity and Permeability: These properties control fluid storage and flow within the reservoir, impacting the reservoir’s pressure regime and its geomechanical response.

3. Pore Pressure

- Initial Pore Pressure: Baseline pressure within the rock’s pore spaces is crucial for defining initial reservoir conditions.

- Pressure Depletion and Injection Effects: Understanding changes in pore pressure during production or fluid injection helps predict compaction, subsidence, and stress redistribution within the reservoir.

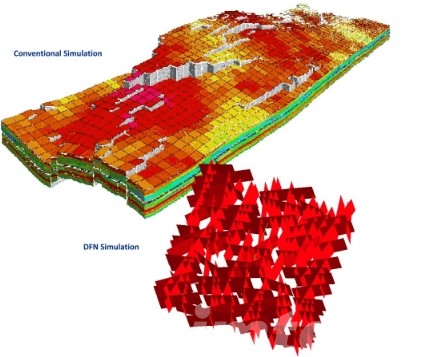

4. Fracture Networks

- Natural Fractures: Pre-existing fractures affect fluid flow and reservoir permeability, impacting hydraulic fracturing and pressure responses during production.

- Fracture Propagation: Modeling how fractures grow under various stress conditions helps in designing fracture stimulation and controlling fracture geometry.

5. Faults and Structural Boundaries

- Fault Position and Orientation: Faults act as pathways or barriers for fluid flow. Their orientation relative to the stress field affects how they might slip or conduct fluids.

- Boundary Conditions: Defined structural boundaries in a geomechanical model influence the reservoir’s stress distribution and must be accurately accounted for to avoid oversimplifications.

6. Thermal Effects

- Temperature Gradients: Temperature changes can affect rock properties and pore pressure, especially in thermal recovery methods like steam injection.

- Thermal Expansion/Contraction: Understanding how rocks expand or contract with temperature changes helps predict deformation and potential changes in stress distribution.

7. Fluid-Rock Interactions

- Chemical Interactions: Some fluid injection methods can alter rock strength or permeability due to chemical reactions.

- Fluid Saturation Effects: Varying fluid saturations can influence rock stiffness and mechanical behavior, affecting stress and fracture patterns.

Applications of Geomechanics in Reservoir Engineering

This chart demonstrates how geomechanics contributes to safer, more efficient, and sustainable reservoir engineering practices, helping engineers tackle operational challenges while maximizing recovery.

| Application Area | Description | Benefits |

| Wellbore Stability Analysis | Analyzing stress and rock properties around the wellbore to prevent collapse during drilling. | Reduces drilling risks, optimizes well placement, and lowers costs. |

| Hydraulic Fracturing Design | Designing hydraulic fracturing networks by understanding stress fields and rock behavior. | Increases production efficiency, improves fracture geometry control. |

| Reservoir Compaction and Subsidence | Assessing the potential for ground subsidence due to fluid extraction and compaction of reservoir rocks. | Protects surface infrastructure and optimizes extraction rates. |

| Sand Production Prediction | Predicting when and where sand particles may dislodge due to changes in pressure and stress. | Minimizes equipment wear and improves production consistency. |

| Enhanced Oil Recovery (EOR) | Using thermal, chemical, or gas injection methods while monitoring geomechanical responses. | Increases recovery rates and prolongs reservoir lifespan. |

| Fault and Fracture Management | Managing fault stability and predicting fracture reactivation during production. | Reduces seismic risks and enhances reservoir safety. |

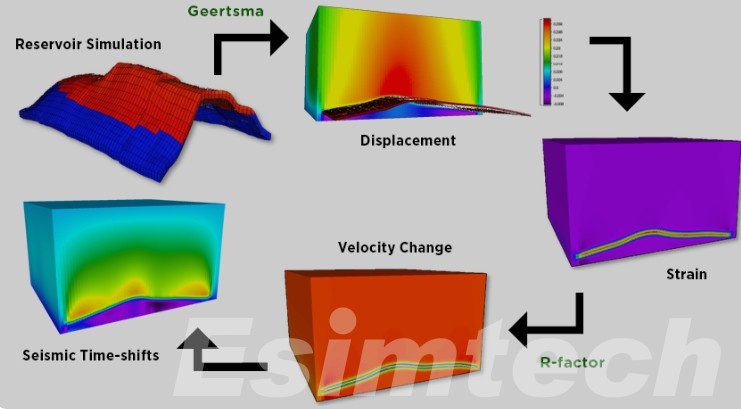

| Reservoir Simulation and Modeling | Integrating geomechanical properties into reservoir models for accurate performance forecasting. | Improves reservoir management and decision-making accuracy. |

| CO₂ Sequestration and Storage | Assessing the feasibility of storing CO₂ safely within geological formations. | Supports sustainable practices and reduces environmental impact. |

| Thermal Recovery Operations | Evaluating rock behavior in thermal recovery methods like steam injection, affecting stress fields. | Enhances recovery from heavy oil reservoirs with controlled stress impact. |

Tools and Technologies in Geomechanics for Reservoir Engineering

Geomechanics in reservoir engineering leverages various tools and technologies that provide insights into rock properties, stress fields, and reservoir behavior under different conditions. These tools facilitate accurate modeling, monitoring, and optimization of drilling, production, and recovery strategies.

1. Well Logging and Core Analysis

- Acoustic/Sonic Logs: Measure the speed of sound waves in the rock formation, providing data on mechanical properties like Young’s modulus and Poisson’s ratio, which are essential for stress and strain analysis.

- Density Logs: Estimate the density of rocks, contributing to stress field calculations and geomechanical modeling.

- Gamma Ray Logs: Detect natural radioactivity to differentiate between rock types and identify potential shale or sandstone formations.

- Core Sampling and Lab Testing: Core samples are collected and analyzed in labs to determine precise rock properties, including compressive strength, porosity, and permeability, providing accurate input for geomechanical models.

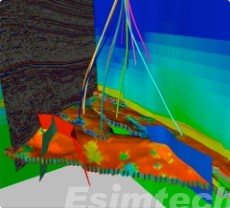

2. 3D Seismic Imaging

- Seismic Surveys: Create 3D models of subsurface formations, showing detailed structural features, fault networks, and stratigraphic layers.

- Seismic Inversion: Converts seismic data into rock property estimates, such as porosity and elasticity, to enhance geomechanical models.

- 4D seismic (time-lapse imaging): Monitors changes in the reservoir over time, which is useful for observing stress and pressure variations due to production or injection activities.

3. Microseismic Monitoring

- Hydraulic Fracturing Monitoring: Captures real-time microseismic events during hydraulic fracturing, helping engineers visualize fracture growth and determine fracture orientation and extent.

- Reservoir Stress Changes: Microseismic monitoring also reveals natural stress changes in response to production or injection activities, which can prevent fault reactivation or compaction issues.

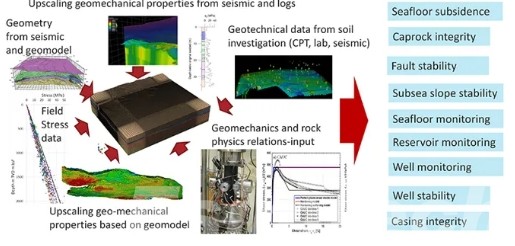

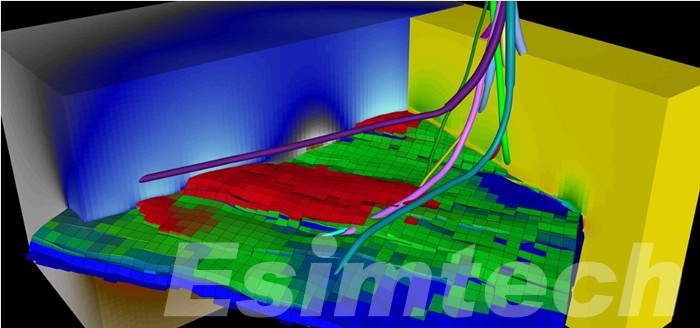

4. Finite Element Analysis (FEA) Software

- Stress-Strain Simulation: FEA software simulates stress and strain within the reservoir, helping engineers analyze wellbore stability, fault activation, and reservoir compaction.

- Fracture Modeling: Simulates hydraulic fracture initiation and propagation, allowing engineers to control fracture geometry and improve production efficiency.

- Reservoir Compaction Analysis: Assesses potential compaction under different production scenarios, helping to avoid excessive subsidence or infrastructure damage.

5. Reservoir Simulation Software with Geomechanics Integration

- Dynamic Simulation Models: Simulate fluid flow, pressure, and rock behavior in the reservoir, allowing for production forecasting and optimization of Enhanced Oil Recovery (EOR) techniques.

- Pore Pressure and Stress Coupling: Simulations that integrate geomechanics and reservoir fluid flow models provide a more accurate prediction of pore pressure changes and their effects on rock mechanics.

- Fault Reactivation Assessment: By simulating stress and pore pressure variations near faults, geomechanical simulations can help avoid unintentional fault slip that could lead to production issues.

6. High-Resolution Downhole Imaging Tools

- Borehole Imaging Tools: Capture images of the wellbore wall, providing detailed data on fractures, faults, and bedding planes.

- Caliper Logs: Measure the diameter of the borehole to detect deformation or collapse zones, aiding in wellbore stability analysis.

- Formation Micro-Imagers (FMI): Deliver high-resolution images of rock texture and fractures, useful for building detailed geomechanical models and understanding fracture networks.

Challenges and Future Directions in Geomechanics for Reservoir Engineering

This chart highlights the need for advanced technologies and integrated solutions to address these challenges, positioning geomechanics to play a significant role in sustainable reservoir engineering practices.

| Challenges | Description | Future Directions | Expected Outcomes |

| Data Integration | Integrating multi-scale data from various sources is complex. | Development of unified data platforms and advanced algorithms for integration. | Seamless data analysis and improved accuracy in geomechanical models. |

| Complex Rock Behavior Modeling | Nonlinear and time-dependent behaviors like creep and plasticity are difficult to model. | Advanced constitutive models and machine learning techniques. | Improved modeling accuracy for complex rock behaviors. |

| Real-Time Monitoring and Analysis | Limited real-time feedback on stress changes during production. | Use of Distributed Acoustic Sensing (DAS) and AI-enhanced data analytics. | Faster decision-making and response to stress-induced changes. |

| Uncertainty in Stress and Pore Pressure | Estimating in-situ stresses and pore pressure is often uncertain. | Enhanced seismic inversion techniques and machine learning predictions. | Reduction in drilling risks and better wellbore stability management. |

| Reservoir Compaction and Subsidence | Production-induced subsidence can lead to infrastructure risks. | Integrated geomechanics-reservoir models and 4D seismic surveys. | Effective prediction and mitigation of subsidence effects. |

| Thermo-Hydro-Mechanical (THM) Coupling | Coupling thermal, hydraulic, and mechanical effects is computationally intensive. | Development of efficient THM simulators and high-performance computing. | More accurate simulations of complex reservoir operations (e.g., EOR). |

| Environmental Impact and Sustainability | Reservoir deformation impacts can affect surface ecology and groundwater systems. | Sustainable reservoir management practices and environmental impact analysis. | Reduction of ecological footprint in resource extraction. |

-1-1024x576_副本.jpg)

In summary, by understanding the mechanical behavior of subsurface formations, reservoir engineers can make informed decisions that maximize production, reduce operational risks, and minimize environmental impact. With ongoing advancements in technology and simulation & modeling techniques in the oil and gas industry, geomechanics will continue to play a critical role in the future of reservoir engineering, supporting the sustainable development of energy resources.