How Downhole Tools are Used in Formation Evaluation

Formation evaluation is a critical aspect of oil and gas exploration and production. It involves the assessment of subsurface geological formations to determine their potential to store and produce hydrocarbons. One of the most effective ways to perform formation evaluation is through the use of downhole tools, which provide real-time data and insights into the characteristics of the geological formations. This article explores the different types of downhole tools used in formation evaluation, their functions, and their impact on the industry.

Introduction to Downhole Tools

Downhole tools are instruments that are deployed into the wellbore to gather data on the geological formations encountered during drilling. These tools are essential for understanding the properties of the rock and fluid in the subsurface, which helps in making informed decisions about well placement, completion, and production strategies. The data collected by downhole tools includes information on porosity, permeability, fluid saturation, and formation pressure, among other parameters.

Types of Downhole Tools Used in Formation Evaluation

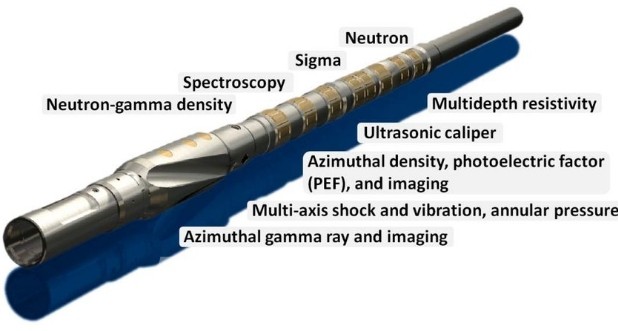

1. Logging While Drilling (LWD) Tools

Function

- Integrated into the bottom hole assembly (BHA) during drilling.

- Logging while drilling Provides real-time data on formation properties such as resistivity, density, porosity, and acoustic velocity.

Types of LWD Tools

- Resistivity Tools: Measure the electrical resistivity of the formation, helping to identify hydrocarbon-bearing zones.

- Density Tools: Use gamma rays to measure the electron density of the formation, which correlates with bulk density and porosity.

- Neutron Tools: Measure hydrogen content, which is indicative of formation porosity.

- Acoustic Tools: Use sonic waves to measure formation acoustic velocity, providing data on rock mechanical properties.

Impact

- Enable real-time decision-making and drilling optimization.

- Reduce non-productive time by providing continuous formation evaluation data.

2. Measurement While Drilling (MWD) Tools

Function

- MWD drilling tools focus on measuring directional parameters of the wellbore such as inclination, azimuth, and toolface orientation.

- Provide information on drilling dynamics, including weight on bit, torque, and vibration.

Impact

- Crucial for directional drilling and precise wellbore placement.

- Maximize hydrocarbon recovery by accurately targeting productive zones and avoiding geological hazards.

3. Wireline Logging Tools

Function

- Deployed into the wellbore on a wireline cable after drilling is completed.

- Wireline logging tools measure a variety of formation properties using electrical, acoustic, nuclear, and magnetic techniques.

Types of Wireline Tools

- Electrical Resistivity Tools: Measure formation resistivity to distinguish between hydrocarbon and water-bearing zones.

- Acoustic Logging Tools: Measure sonic wave travel times to determine formation porosity and mechanical properties.

- Nuclear Logging Tools: Include gamma ray, density, and neutron tools for evaluating lithology and porosity.

- Magnetic Resonance Imaging (MRI) Tools: Provide detailed information on porosity, fluid types, and permeability.

Impact

- Provide high-resolution data for accurate reservoir characterization.

- Essential for comprehensive formation evaluation and reserve estimation.

4. Coring Tools

Function

- Used to extract cylindrical core samples from subsurface formations.

- Provide direct physical evidence of rock and fluid properties.

Types of Coring Tools

- Conventional Coring Tools: Cut a cylindrical sample from the formation and retrieve it to the surface.

- Sidewall Coring Tools: Obtain small core samples from the sidewall of the borehole.

Impact

- Allow for detailed laboratory analysis of rock and fluid properties.

- Provide critical data for understanding reservoir characteristics, including porosity, permeability, and mineralogy.

5. Pressure and Sampling Tools

Function

- Measure formation pressure and obtain fluid samples from the reservoir.

- Used to assess formation fluid properties and pressure regimes.

Types of Pressure and Sampling Tools

- Formation Testers: Measure formation pressure and take fluid samples at different depths.

- Wireline Formation Testing (WFT) Tools: Provide real-time pressure data and fluid samples during wireline logging operations.

Impact

- Provide accurate formation pressure data and fluid samples for reservoir evaluation.

- Essential for understanding reservoir behavior, fluid contacts, and production potential.

6. Borehole Imaging Tools

Function

- Provide high-resolution images of the borehole wall.

- Used to evaluate borehole conditions, fracture identification, and sedimentary structures.

Types of Borehole Imaging Tools

- Optical Imaging Tools: Use cameras and lights to capture visual images of the borehole wall.

- Acoustic Imaging Tools: Use ultrasonic waves to create detailed images of the borehole wall.

Impact

- Enable detailed analysis of borehole conditions and geological features.

- Improve understanding of formation structures and fracture networks.

Various Simulation Technology Used in Downhole Tools for Formation Evaluation

Simulation technology plays a vital role in the design, development, and operation of downhole tools used for formation evaluation in the oil and gas industry. These advanced technologies enable engineers to predict the performance of downhole tools, optimize their design, and improve the accuracy and efficiency of formation evaluation.

1. Finite Element Analysis (FEA)

- Function: FEA is used to simulate and analyze the mechanical behavior of downhole tools under various conditions. It helps in understanding stress distribution, deformation, and potential failure points.

- Applications: Rotor design, structural integrity analysis, material selection, and fatigue analysis.

- Impact: Enhances the durability and reliability of downhole tools by ensuring they can withstand harsh downhole environments.

2. Computational Fluid Dynamics (CFD)

- Function: CFD simulates the flow of fluids around and through downhole tools. It helps in optimizing the design of tools for better fluid dynamics and minimizing flow-related issues.

- Applications: Mud flow optimization, erosion prediction, and hydraulic efficiency improvement.

- Impact: Improves the efficiency of fluid flow through downhole tools, reducing energy consumption and enhancing tool performance.

3. Acoustic and Sonic Modeling

- Function: This technology simulates the propagation of acoustic waves through geological formations and downhole tools. It helps in optimizing the design of acoustic logging tools and interpreting the data they collect.

- Applications: Acoustic logging tool design, sonic wave propagation analysis, and data interpretation enhancement.

- Impact: Increases the accuracy of acoustic logging tools, leading to better formation evaluation and reservoir characterization.

4. Electromagnetic (EM) Modeling

- Function: EM modeling simulates the behavior of electromagnetic fields in and around downhole tools. It is used to design and optimize tools that measure formation resistivity and other EM properties.

- Applications: Resistivity tool design, EM field analysis, and data interpretation improvement.

- Impact: Enhances the accuracy of resistivity measurements, providing better identification of hydrocarbon-bearing zones.

5. Thermal Simulation

- Function: Thermal simulation models the temperature distribution and heat transfer within downhole tools and surrounding formations. It helps in designing tools that can operate effectively in high-temperature environments.

- Applications: High-temperature tool design, thermal stress analysis, and heat dissipation optimization.

- Impact: Ensures the reliable operation of downhole tools in high-temperature conditions, improving their lifespan and performance.

6. Dynamic Simulation

- Function: Dynamic simulation models the real-time behavior of downhole tools during drilling and formation evaluation operations. It helps in predicting tool performance and optimizing operational parameters.

- Applications: Drilling dynamics analysis, tool vibration prediction, and real-time performance optimization.

- Impact: Improves the operational efficiency and safety of downhole tools, reducing the risk of tool failure and operational downtime.

Conclusion

Formation evaluation using downhole tools is a vital component of the oil and gas industry. By providing real-time and high-resolution data on formation properties, these tools enable accurate reservoir characterization, optimize well placement, and enhance hydrocarbon recovery.