How Does Well Acidizing Function Enhancing Well Production

As oil and gas wells age, their production rates naturally diminish due to several factors, such as formation damage from mineral deposits, remnants of drilling mud, or the accumulation of scale. Enter well acidizing, a proven technique designed to efficiently eliminate these obstructions and revive a well’s production capacity.

What is Well Acidizing?

Well acidizing is a well stimulation technique with a long and proven history in the oil and gas industry. It’s a targeted approach that addresses a specific culprit behind declining well production: formation damage.

Formation damage is a broad term encompassing various materials that accumulate within the reservoir rock over time, hindering the flow of oil and gas into the wellbore. These damaging materials can originate from several sources:

- Mineral Deposits: Naturally occurring minerals like calcium carbonate (a key component of limestone) can precipitate from formation fluids and form scale buildup within the rock matrix or near the wellbore.

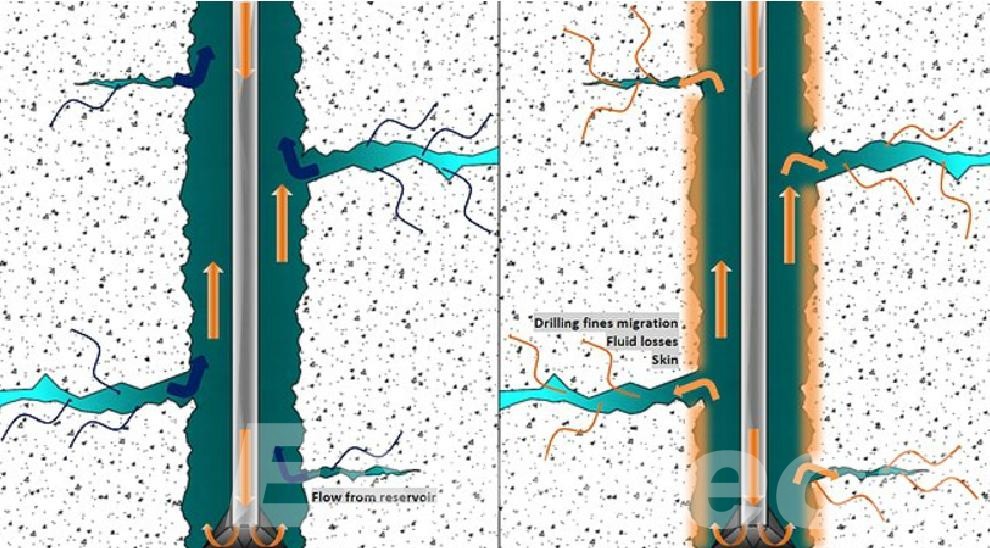

- Drilling Mud Residue: During the well drilling process, mud is used to lubricate the drill bit, cool the wellbore, and maintain wellbore stability. However, some mud residue can inadvertently enter the formation and restrict flow paths.

- Organic Material: Degradation of organic matter present within the reservoir rock can create byproducts that clog pore spaces and hinder fluid flow.

These formation damage materials act like tiny roadblocks within the rock, significantly increasing the difficulty for oil and gas to flow towards the wellbore. This translates to a decline in well production rates.

Well acidizing tackles this challenge head-on by utilizing various acids pumped downhole. The specific type of acid chosen depends on the composition of the formation damage. Here’s a closer look:

- Matching the Acid to the Damage: For instance, hydrochloric acid (HCL) is highly effective in dissolving carbonate minerals commonly found in scale buildup. Organic acids are used for a wider range of scale deposits or formation minerals. In specific situations, hydrofluoric acid (HF) might be considered for particularly stubborn minerals like clays or silica, but due to safety concerns, its use is often limited and requires extra planning and precautions.

By carefully selecting the appropriate acid and ensuring its effective placement within the reservoir, well acidizing treatments can dissolve these formation damage materials, restoring the natural permeability of the rock and enabling oil and gas to flow more freely into the wellbore, leading to a significant increase in production rates.

How Does Well Acidizing Enhance Production?

Well acidizing tackles these damages head-on, enhancing production in several ways:

- Increased Permeability: The primary benefit lies in improved permeability, the rock’s ability to allow fluids to flow through it. By dissolving formation damage, acidizing enlarges existing pores and even creates new pathways within the rock matrix. This enhanced permeability allows oil and gas to flow more freely from the reservoir into the wellbore, significantly increasing production rates.

- Targeted Removal of Blockages: Acid formulations can be tailored to target specific types of damage. For instance, hydrochloric acid effectively dissolves carbonate scale, while organic acids can address a wider range of scale deposits and formation minerals. This targeted approach ensures that the acid attacks the problematic materials without harming the reservoir rock itself.

- Near-Wellbore Cleanliness: Formation damage often concentrates near the wellbore, hindering the crucial connection between the well and the reservoir. Acidizing effectively removes debris like mud residue or scale deposits in this critical zone. This improved wellbore cleanliness allows for better communication between the wellbore and the reservoir, further boosting production efficiency.

- Uniform Treatment: Modern well acidizing techniques utilize specialized pumping systems and diverting agents to ensure a uniform distribution of acid within the targeted formation zone. Diverting agents temporarily block flow paths in undesired zones, directing the acid towards the areas with the most significant formation damage. This ensures that the entire treatment zone benefits from the acidizing process, maximizing its effectiveness in restoring well productivity.

In summary, well acidizing acts like a surgical procedure for wellbore blockages. By dissolving formation damage, increasing permeability, and promoting near-wellbore cleanliness, it effectively removes the chokehold on production, allowing oil and gas to flow more freely and significantly enhancing well productivity. This not only leads to increased output but also helps extend the economic life of mature wells.

What are Well Acidizing Technologies?

Well acidizing relies on a combination of technologies to ensure a safe, effective, and targeted treatment. Here’s a deeper dive into some key technologies:

1. Acid Pumping Systems: Specialized pumps are used to precisely inject the acidizing fluids downhole at the desired pressure and rate. These pumps can be deployed through various means:

- Tubing Pumping: For wells with downhole tubing in place, acid can be injected directly through the tubing string.

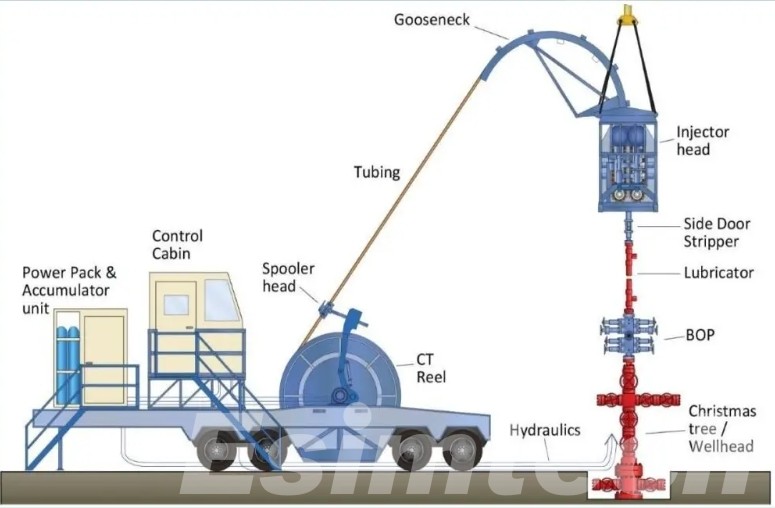

- Coiled Tubing Units: Coiled tubing, a flexible continuous pipe, allows for acid injection without the need for well intervention rigs. This method offers greater wellbore access and maneuverability.

- Nitrogen Lift-assisted Acidizing: In some cases, nitrogen gas can be co-injected with the acidizing fluids. The nitrogen helps lift the acid deeper into the formation and enhances its cleaning effectiveness.

2. Diverting Agents: Reservoir formations can have varying degrees of permeability. To ensure the acid reaches the zones with the most significant formation damage, diverting agents might be employed. These agents come in various forms:

- Mechanical Diverters: These temporary plugs or packers isolate unwanted zones within the formation, directing the acidizing fluids towards the targeted areas.

- Chemical Diverters: These specialized chemicals interact with the formation rock, altering its permeability and directing the acid flow towards the zones with the greatest need.

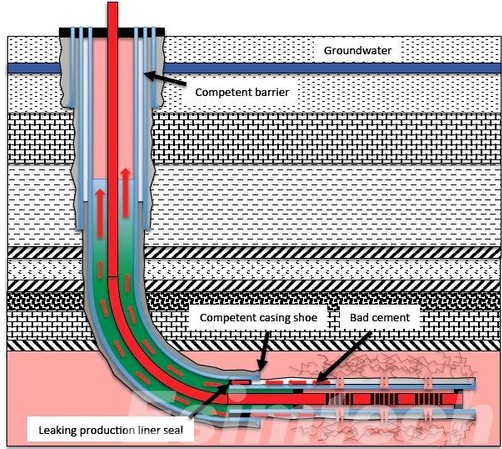

3. Downhole Monitoring Tools: Real-time monitoring plays a crucial role in optimizing the acidizing treatment. Downhole tools like pressure gauges, temperature sensors, and production logging tools provide valuable data on:

- Acid Placement: These tools track the movement of the acidizing fluids downhole, ensuring they reach the targeted zones within the reservoir.

- Treatment Effectiveness: Real-time data on pressure changes and fluid flow helps assess the effectiveness of the acidizing treatment in dissolving formation damage.

- Wellbore Integrity: Monitoring tools can detect any potential issues with the wellbore integrity during the acidizing process, allowing for immediate intervention if necessary.

By leveraging these well acidizing technologies, well intervention specialists can tailor the treatment to achieve optimal results. Precise acid placement, effective diversion techniques, and real-time monitoring ensure a safe, efficient, and targeted approach, maximizing the production-enhancing benefits of well acidizing.

Conclusion

Well acidizing is a powerful well stimulation technique that effectively addresses formation damage and enhances oil and gas production. By dissolving blockages and improving reservoir permeability, acidizing helps restore a well’s productivity potential, leading to increased output and extending the economic life of mature wells.