How Does Gamma Ray Logging Contribute to the Identification of Hydrocarbon Reservoirs

Gamma ray logging is a widely used geophysical method in the oil and gas industry for identifying and characterizing rock formations during the drilling process. This technique plays a crucial role in determining the composition of subsurface formations, particularly in distinguishing between different types of rocks such as shale, sandstone, and limestone, which is essential for evaluating potential hydrocarbon reservoirs.

How Gamma Ray Logging Works

Principle

Naturally occurring radioactive elements like potassium-40, uranium, and thorium are present in varying concentrations in different types of rocks. Shale formations, in particular, tend to have higher concentrations of these elements. As these radioactive isotopes decay, they emit gamma rays, which can be detected and measured.

Key Steps

1. Logging Tool Setup

The gamma ray logging tool, equipped with a gamma ray detector, is lowered into the wellbore either during or after drilling. The tool travels down the well, continuously measuring the gamma radiation emitted by the surrounding rocks.

2. Gamma Ray Detection

As the tool moves through different rock formations, it detects the natural gamma radiation emitted by the surrounding formations. The detector inside the logging tool captures the intensity of gamma rays, which is then converted into electrical signals.

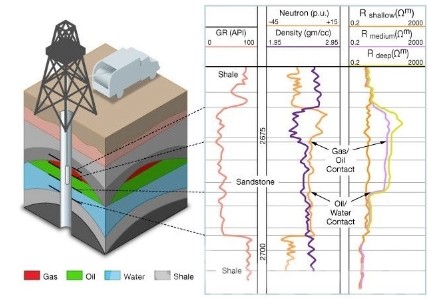

3. Recording Gamma Ray Intensity

The intensity of gamma radiation is recorded continuously as the tool is moved through the wellbore. The data is plotted on a gamma ray log, which displays the variation in gamma ray intensity as a function of depth.

- High Gamma Ray Values: Shale formations typically emit higher levels of gamma radiation due to their higher content of radioactive elements.

- Low Gamma Ray Values: Non-shale formations like sandstone, carbonate, or clean reservoir rocks exhibit lower levels of gamma radiation.

4. Formation Identification

The gamma ray log allows geologists to differentiate between shale (high gamma readings) and cleaner reservoir rocks (low gamma readings). This identification is crucial for determining potential hydrocarbon-bearing zones and correlating rock layers between different wells.

5. Data Interpretation

Geologists analyze the gamma ray log to assess the rock composition, estimate shale content, and identify lithological boundaries. The gamma ray data is often combined with other logs (such as resistivity and porosity logs) for a more comprehensive interpretation of the subsurface geology.

6. Real-Time Data During Drilling

Modern gamma ray logging tools can be used in real-time while drilling, allowing operators to make quick decisions about wellbore placement and direction based on the gamma ray data. This helps avoid drilling into non-reservoir zones and optimizes well positioning for hydrocarbon extraction.

Applications of Gamma Ray Logging in Oil and Gas Exploration

- Lithology Identification: Gamma ray logging is primarily used to differentiate between shale (which has high gamma radiation due to its clay content) and non-shale formations like sandstones or limestones. This helps identify reservoir zones, where hydrocarbons are more likely to be found.

- Shale Content Estimation: Since shales have higher concentrations of radioactive elements, gamma ray logs can be used to estimate the shale content in a particular rock formation. This is particularly important for reservoir quality evaluation, as excessive shale content can negatively impact the reservoir’s permeability and porosity.

- Facies Analysis: Gamma ray logs are used in sedimentary facies analysis to infer depositional environments. Variations in gamma ray levels can indicate changes in the depositional setting, such as the transition from a shale-dominated deep marine environment to a sandstone-rich deltaic environment.

- Well Correlation: By comparing gamma ray logs from different wells, geologists can correlate rock formations across a field or region. This helps in constructing geological models of subsurface structures and understanding the distribution of reservoir rocks.

- Porosity and Permeability Indications: Although gamma ray logs do not directly measure porosity or permeability, the data can be used in combination with other logs to infer these properties. For example, low gamma ray readings in conjunction with high resistivity and porosity logs often indicate clean reservoir rocks with high hydrocarbon potential.

Advantages of Gamma Ray Logging

| Advantage | Description |

| Non-Invasive | Gamma ray logging is a passive technique, requiring no physical contact or sampling of the formation. |

| Real-Time Data | Provides real-time subsurface geological data during drilling, allowing immediate decision-making. |

| Shale and Lithology Identification | Differentiates between shale and reservoir rocks, aiding in accurate formation mapping. |

| Cost-Effective | Low operational costs compared to other logging methods, making it widely used for formation evaluation. |

| Well Correlation | Helps correlate geological layers between different wells, enhancing field-wide geological understanding. |

| Versatile in Various Rock Types | Effective in a wide range of lithologies, from sandstones to carbonates and shales. |

| Minimal Environmental Impact | Non-destructive method with minimal impact on the environment or wellbore integrity. |

| Simple Interpretation | Easy to interpret, offering clear identification of high-radioactivity zones associated with shale. |

Limitations and Considerations in Gamma Ray Logging

This chart highlights some of the key challenges and considerations when using gamma-ray logging in oil and gas exploration, along with approaches to mitigate these limitations.

| Limitations | Description | Impact | Mitigation Approach |

| Shale Content Interference | Gamma ray logging detects radiation primarily from shale but can misinterpret non-shale formations with high natural radioactivity. | This can lead to incorrect identification of rock types and formations. | Combine with other logging tools (e.g., resistivity logs) to differentiate between shale and other radioactive rocks. |

| Tool Sensitivity to Casing | Gamma ray detectors may lose sensitivity in cased wells, affecting the accuracy of measurements. | Results in diminished log precision, especially in older or complex wells. | Use advanced logging tools designed for cased wells, or account for casing impact in data interpretation. |

| Limited Depth of Investigation | Gamma-ray logging only measures radioactivity in the immediate vicinity of the wellbore. | Provides limited information about the larger formation. | Combine with deeper-penetrating tools such as neutron or density logs for a more comprehensive formation analysis. |

| Environmental and Borehole Effects | Temperature, pressure, borehole size, and fluid type can affect gamma ray readings. | Leads to potential measurement inaccuracies in different well conditions. | Calibrate tools to specific well conditions and use correction algorithms to compensate for environmental variations. |

| Radioactive Sources in Drilling Fluid | Drilling fluids containing potassium or other radioactive elements can interfere with gamma ray measurements. | Misinterpretation of results due to contamination from the drilling process. | Monitor drilling fluid composition and remove or account for radioactive materials during logging. |

| Resolution Limitations | Gamma ray logs may lack resolution to detect thin beds or small variations in rock composition. | Misses fine geological details or subtle changes in lithology. | Use high-resolution tools or combine with other high-resolution techniques like micro-resistivity logging. |

| Radiation Safety Concerns | Handling of radioactive materials requires strict safety protocols and regulatory compliance. | Increases operational complexity and costs. | Follow rigorous safety guidelines and use non-nuclear alternatives when feasible. |

| Cost and Complexity | Advanced gamma ray logging tools and techniques can be expensive and require specialized expertise. | Higher operational costs and potential delays if issues arise with the tool or data interpretation. | Conduct cost-benefit analysis and train personnel to ensure efficient use of advanced tools. |

How Simulation Tools are Used for Optimizing Gamma Ray Logging

Oil ans gas simulation tools play a critical role in enhancing the accuracy and efficiency of gamma-ray logging.

1. Pre-Logging Scenario Testing

- Purpose: Simulations are used to model various geological scenarios before logging operations.

- Benefits: This helps in predicting gamma-ray responses in different rock formations and optimizing tool settings for accurate measurements.

2. Calibration and Tool Design

- Purpose: Simulation software is employed to test and calibrate gamma ray logging tools under various conditions.

- Benefits: It ensures the logging tool is properly designed and fine-tuned for different rock types, well conditions, and depths, reducing the need for field testing.

3. Noise Reduction and Signal Processing

- Purpose: Simulation helps develop advanced algorithms for noise filtering and signal enhancement during gamma-ray data acquisition.

- Benefits: This improves data clarity and accuracy, especially in noisy or complex well environments.

4. Formation Evaluation and Interpretation

- Purpose: Simulation tools allow the modeling of geological formations and the corresponding gamma-ray response.

- Benefits: This assists in better interpretation of real-time data, helping geologists and engineers differentiate between lithologies like shale, sandstone, and other reservoir rocks.

5. Optimization of Logging Parameters

- Purpose: Well logging simulation tools are used to optimize tool placement, logging speed, and measurement parameters based on geological conditions.

- Benefits: This improves data acquisition efficiency, minimizing time and costs associated with repeated or inaccurate logging passes.

6. Predictive Modeling for Complex Formations

- Purpose: In complex geological settings, simulation tools predict gamma-ray responses to guide logging operations.

- Benefits: It enhances decision-making by providing insights into expected challenges and optimal tool settings.

7. Post-Logging Analysis

- Purpose: After data is collected, simulation tools assist in analyzing the results against modeled scenarios.

- Benefits: This allows for a more refined interpretation of the gamma-ray logs, improving the accuracy of formation evaluation.

Overall, the ability to distinguish between shale and non-shale rocks of gamma-ray logging, combined with its cost-effectiveness and real-time capabilities, makes it an invaluable tool in both oil and gas exploration and production. Despite its limitations, when used in conjunction with other logging methods, gamma ray logging significantly contributes to the successful identification of hydrocarbon reservoirs. Simulation tools do a great favor in enhancing the precision, efficiency, and effectiveness of gamma ray logging in oil and gas exploration.