How Do Semisubmersibles Work

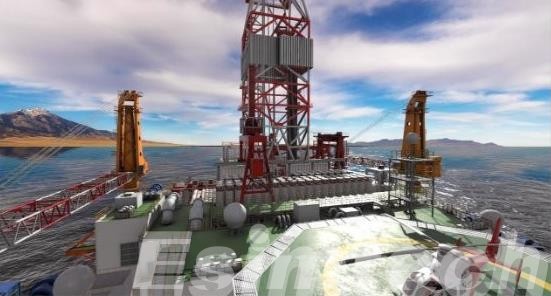

Semisubmersibles are a critical component in the offshore oil and gas industry, providing a stable platform for drilling and production operations in deep waters. This article delves into the function and components of semisubmersibles, their working principles, and how one can learn to operate these sophisticated structures.

Function and Components of Semisubmersibles

Semisubmersibles are a cornerstone of offshore oil and gas operations, providing a stable and versatile platform for drilling and production in deep and ultra-deep waters.

Function of Semisubmersibles

The primary function of semisubmersibles is to serve as a stable platform for drilling, production, and other offshore operations in environments where fixed structures like oil rigs are impractical. Their unique design allows them to operate in deep waters and harsh marine conditions, providing several advantages:

- Stability: Semisubmersibles are designed to minimize movement caused by waves, wind, and currents. Their partially submerged structure provides stability, making them ideal for precise drilling operations.

- Mobility: Unlike fixed platforms, semisubmersibles can be relocated to different drilling sites. This mobility makes them versatile assets for exploration and development in various offshore fields.

- Versatility: Semisubmersibles can support a wide range of activities, including drilling, well intervention, production, and even accommodation facilities for crew members.

- Safety: Elevated decks keep critical operations and personnel above the wave action, enhancing safety in rough seas.

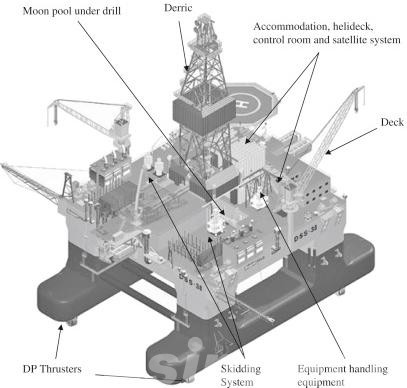

Components of Semisubmersibles

1. Hull

The hull is the core structure that ensures the semisubmersible stays afloat and stable. It comprises two main parts:

- Pontoons: These large, watertight structures are located at the bottom of the hull and provide the primary buoyancy for the platform. By being submerged below the waterline, pontoons reduce the impact of waves and currents, contributing to the platform’s stability.

- Vertical Columns: These columns connect the pontoons to the deck and add buoyancy and stability. The height of the columns elevates the deck above the water surface, minimizing the effects of waves and ensuring a safer operational environment.

2. Deck

The deck is the operational heart of the semisubmersible, housing essential equipment and facilities:

- Drilling Rig: The main structure on the deck, equipped with a derrick, drill string, and other necessary drilling equipment. This is where the primary drilling operations are conducted.

- Crew Quarters: Living accommodations for the crew, including sleeping areas, kitchens, and recreational facilities. These quarters ensure that crew members can live comfortably while working offshore for extended periods.

- Operational Facilities: Offices, control rooms, and other spaces needed for managing the drilling and production processes. These facilities are essential for the day-to-day operations and management of the platform.

3. Ballast System

The ballast system is crucial for maintaining the semisubmersible’s stability and position in the water. It consists of several ballast tanks that can be filled with water or air to adjust buoyancy and balance:

- Ballast Pumps: These pumps move water in and out of the ballast tanks, allowing operators to control the platform’s draft (the depth below the waterline) and stability.

- Control Systems: Automated systems that monitor and adjust the ballast levels to ensure the platform remains stable and level, even in changing sea conditions.

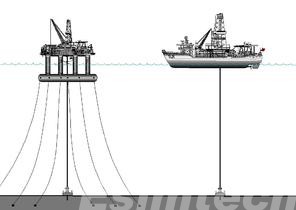

4. Mooring System

The mooring system keeps the semisubmersible anchored in its designated location, essential for stability during drilling operations:

- Anchored Mooring: Uses a network of anchors and chains or cables secured to the seabed. This traditional method provides strong and reliable positional stability, especially in shallower waters.

- Dynamic Positioning (DP): An advanced system that employs thrusters and computer control to maintain the platform’s position without the need for anchors. DP is particularly useful in deepwater environments where traditional mooring is challenging.

5. Drilling Equipment

Drilling equipment is vital for the semisubmersible’s primary function of extracting oil and gas:

- Derrick: The tall structure on the deck that supports the drill string and allows vertical movement during drilling operations.

- Drill String: A series of connected pipes that transmit the rotational power from the surface to the drill bit, facilitating the drilling process.

- Blowout Preventer (BOP): A critical safety device installed on the wellhead. The BOP prevents uncontrolled releases of oil or gas (blowouts) by sealing the well in emergencies.

- Auxiliary Systems

Several auxiliary systems support the semisubmersible’s main operations, ensuring safety and efficiency:

- Power Generation: Typically provided by diesel generators or gas turbines, these systems supply the electricity needed for drilling operations, crew accommodations, and other onboard systems.

- Safety and Emergency Systems: These include lifeboats, fire suppression systems, and emergency communication equipment. They are crucial for protecting the crew and ensuring swift responses to emergencies.

- Navigation and Communication Systems: Advanced navigation systems ensure accurate positioning of the platform, while robust communication systems maintain contact with onshore bases and other vessels, facilitating coordination and safety.

Working Principle Semisubmersibles

The working principle of a semisubmersible revolves around achieving and maintaining stability in a dynamic ocean environment. Here’s a deeper dive into the interplay of forces that keeps these platforms steady:

- Buoyancy Control: As mentioned earlier, the submerged pontoons trap air, generating a natural upward force that counteracts the weight of the platform and keeps it afloat. This concept is similar to how a ship floats, but with a crucial difference. Unlike a ship’s hull displacing water, a semisubmersible’s buoyancy comes from the air trapped within the pontoons.

- Center of Buoyancy (CB) and Center of Gravity (CG): Stability hinges on the delicate balance between two key forces:

- Center of Buoyancy (CB): This is the point where the upward buoyant force acts on the semisubmersible. Imagine it as the center of all the upward lift generated by the pontoons.

- Center of Gravity (CG): This represents the point where the entire weight of the platform, including the working deck, equipment, and personnel, is concentrated.

For optimal stability, the CB and CG need to be in close proximity, ideally with the CB slightly above the CG. This creates a righting moment, meaning that if the platform tilts due to waves or wind, the buoyant force acting at the CB will push back and restore the platform to its upright position.

- Ballast Water System: This ingenious system plays a crucial role in maintaining the CB-CG relationship. By carefully controlling the amount of water in the ballast tanks, the operator can adjust the overall weight and submergence of the platform. Taking on ballast water lowers the CB, bringing it closer to the CG and enhancing stability during operations like drilling. Conversely, expelling ballast water raises the CB relative to the CG, making the platform more buoyant for towing or repositioning.

- Mooring Systems: While buoyancy and ballast water management provide inherent stability, semisubmersibles also rely on mooring systems to maintain their position in the face of currents and waves. These systems can involve:

- Anchor Lines: Multiple anchor lines extend from the platform to the seabed, tethering it to a specific location.

- Dynamic Positioning (DP): This system utilizes advanced thruster technology and positioning software to maintain the platform’s location electronically, even in challenging conditions.

- Environmental Factors: Wind, waves, and currents constantly exert forces on a semisubmersible. The platform’s design and operational procedures consider these factors to ensure stability. For instance, the shape of the pontoons minimizes wave resistance, and computer-controlled systems can adjust ballast or thruster operation to counteract wave-induced movements.

By meticulously managing buoyancy, ballast water, and mooring systems, semisubmersibles achieve remarkable stability, enabling them to function effectively in the ever-changing ocean environment. This intricate interplay of forces is a testament to the ingenuity of marine engineering, allowing humans to tap into the vast resources hidden beneath the sea’s surface.

How to Learn Semisubmersibles Operations

The world of semisubmersible operations is vast and requires specialized knowledge and training. Here are some avenues to explore the ways:

Formal Education and Training Programs

- Maritime Academies and Universities: Many institutions offer accredited programs in Offshore Engineering or Marine Operations that cover the design, function, and operation of semisubmersibles. These programs may include theoretical coursework, simulator training, and even internships on actual rigs.

- Industry Certifications: Depending on your career aspirations, specific industry certifications might be required. Organizations like the International Marine Contractors Association (IMCA) offer certifications in areas like mooring, dynamic positioning, and offshore installations.

Online Resources and Self-Learning

- Interactive Learning Platforms: Several online platforms offer interactive modules or courses on semisubmersibles. These resources can provide a basic understanding of the components, working principles, and operational procedures involved.

- Technical Publications and Industry Websites: Leading oil and gas companies and maritime engineering organizations often publish detailed articles and white papers on semisubmersibles. These resources offer in-depth information on specific aspects of their design and operation.

Oil Rig Drilling Simulation

Oil rig drilling simulations can be a particularly valuable tool for gaining practical experience in a safe and controlled environment. These simulations often replicate the control room of a semisubmersible, allowing users to:

- Practice Well Planning: Users can learn to plan and optimize drilling trajectories considering geological formations and wellbore stability.

- Simulate Drilling Operations: The simulation software might allow users to experience the entire drilling process, including managing downhole pressure, tripping drill pipe, and handling potential wellbore issues.

- Test Emergency Procedures: Simulations can provide a safe platform to practice emergency response procedures in scenarios like blowouts, equipment failure, or severe weather conditions.

Conclusion

Semisubmersibles are a testament to human ingenuity. Their ability to operate in harsh environments has revolutionized offshore exploration and production. By understanding their function, components, and working principles, we gain a deeper appreciation for these technological marvels that unlock the riches hidden beneath the ocean’s surface.