How CCUS Contributes to Emission Reduction in the Oil and Gas Industry

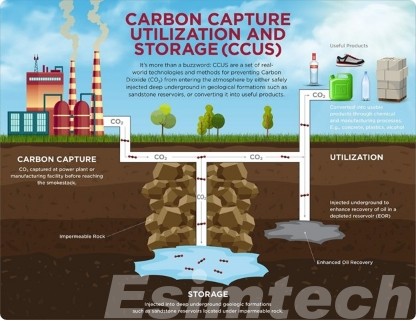

The oil and gas industry, a major contributor to global carbon dioxide (CO₂) emissions, faces growing pressure to reduce its environmental impact. One of the most promising solutions is Carbon Capture Utilization and Storage (CCUS), a set of technologies designed to capture CO₂ emissions from industrial sources, store them safely underground, or repurpose the CO₂ for practical uses. For the oil and gas industry, CCUS not only reduces emissions but also creates new opportunities for efficiency and sustainability.

Understanding CCUS in the Oil and Gas Sector

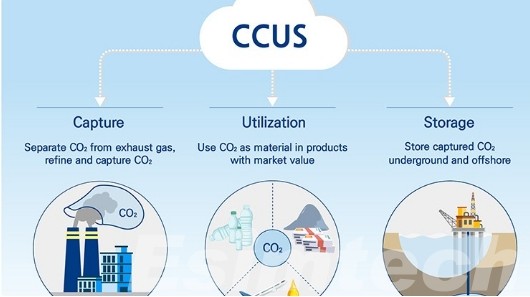

CCUS carbon capture technologies involve three key stages

- Carbon Capture: CO₂ is captured from sources like oil refineries, gas processing plants, and power generation facilities. Technologies such as post-combustion, pre-combustion, and oxy-fuel combustion are commonly used in oil and gas operations to capture CO₂ before it is released into the atmosphere.

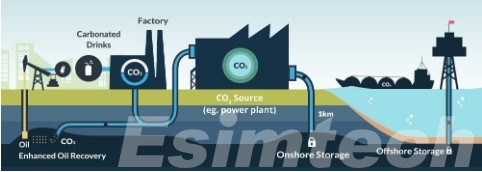

- Utilization: Captured CO₂ can be repurposed for various industrial applications. In the oil and gas industry, Enhanced Oil Recovery (EOR) is a common practice where CO₂ is injected into aging oil reservoirs to boost oil extraction. Additionally, CO₂ is used in the production of synthetic fuels, chemicals, and even construction materials.

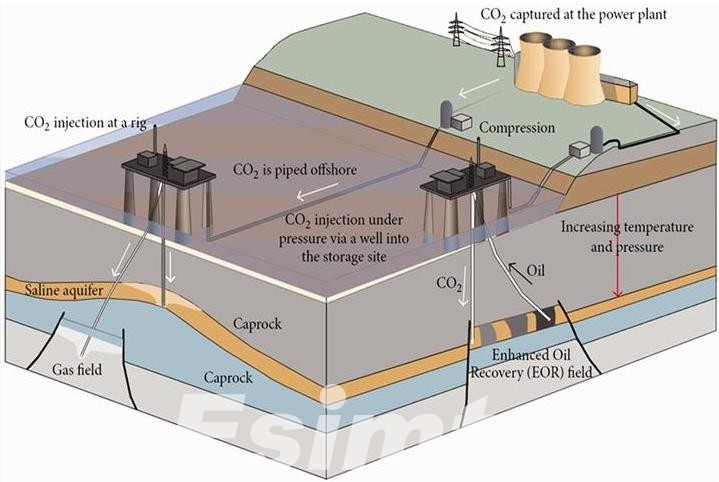

- Storage: If CO₂ cannot be utilized, it is injected deep underground into geological formations, such as depleted oil and gas reservoirs or saline aquifers. This process ensures that CO₂ is stored securely and prevented from re-entering the atmosphere.

Applications of CCUS in the Oil and Gas Industry

The oil and gas sector is well-positioned to adopt CCUS carbon capture technologies due to its extensive experience in managing subsurface reservoirs and large-scale industrial operations.

1. Enhanced Oil Recovery (EOR)

One of the most established uses of CCUS in the oil and gas industry is Enhanced Oil Recovery. In this process, captured CO₂ is injected into mature oil fields to increase pressure and improve the flow of oil. The injected CO₂ helps extract additional oil from reservoirs that would otherwise be left behind after primary and secondary recovery methods.

EOR has a dual benefit: not only does it extend the productive life of oil fields, but it also traps significant amounts of CO₂ underground. This makes EOR a key application for both improving oil recovery and reducing carbon emissions.

2. Decarbonizing Gas Processing

Natural gas production often involves removing CO₂ from the gas before it is sent to market. This process, known as gas sweetening, generates significant amounts of CO₂ that would traditionally be released into the atmosphere. By integrating CCUS into gas processing, companies can capture and store this CO₂, effectively reducing their overall emissions.

3. Carbon Capture from Hydrogen Production

Hydrogen is increasingly viewed as a clean energy carrier, and many oil and gas companies are exploring hydrogen production as part of their energy transition strategies. However, traditional hydrogen production methods, such as steam methane reforming (SMR), generate CO₂ as a byproduct. CCUS can capture the CO₂ produced during hydrogen production, enabling the creation of blue hydrogen, a lower-carbon form of hydrogen.

4. Decarbonizing Refineries and Petrochemical Plants

Oil refineries and petrochemical plants are significant sources of CO₂ emissions. Integrating CCUS into these facilities can capture emissions from combustion processes, hydrogen production, and chemical manufacturing, allowing the oil and gas industry to decarbonize its refining operations while maintaining high production levels.

The Benefits of CCUS used for the Oil and Gas Industry

1. Reduction of Carbon Emissions

The most prominent benefit of CCUS is its ability to drastically reduce CO₂ emissions from oil and gas operations. By capturing CO₂ at various points in the production process and preventing it from entering the atmosphere, CCUS helps mitigate the industry’s impact on global warming. This is especially important as regulatory pressures to reduce emissions continue to increase.

2. Compliance with Regulatory and Climate Targets

With governments around the world implementing stricter emissions regulations and setting ambitious climate targets, CCUS allows the oil and gas industry to comply with these rules. Meeting emissions standards through CCUS helps companies avoid penalties or additional costs associated with carbon taxes. Moreover, companies that adopt CCUS can participate in carbon credit markets, generating financial returns from reducing emissions.

3. New Revenue Streams from CO₂ Utilization

Captured CO₂ can be used in various industrial applications, including the production of chemicals, synthetic fuels, and building materials. This creates new revenue streams from what was once considered waste. CO₂ is also valuable in certain agricultural processes, food preservation, and carbonation, offering diverse utilization options.

4. Maximizing Resource Efficiency

CCUS technologies, particularly in EOR, enable oil companies to extract more resources from existing fields. This reduces the need for new exploration and drilling projects, lowering the environmental and financial costs associated with developing new reserves. Optimizing resource recovery from existing assets is key to the industry’s long-term sustainability.

5. Supporting Energy Transition

As the global energy mix shifts toward renewables, the oil and gas industry is under pressure to reduce its carbon intensity. CCUS is a crucial technology that allows the sector to contribute to the transition while continuing to provide energy. It supports the development of cleaner fuels, such as blue hydrogen, and reduces emissions from core operations, ensuring the industry can adapt to changing energy dynamics.

6. Long–Term Storage of CO₂

For CO₂ that cannot be utilized, CCUS provides a secure and permanent solution for long-term storage in geological formations, such as depleted oil and gas fields or saline aquifers. This prevents CO₂ from re-entering the atmosphere and contributing to climate change over the long term.

7. Job Creation and Economic Growth

Developing and scaling up CCUS infrastructure can create new jobs in engineering, construction, and operations. As CCUS projects expand, they can stimulate economic growth, particularly in regions with significant oil and gas activities. This contributes to a just transition, balancing environmental concerns with economic opportunities.

Challenges and Future Outlook for CCUS Used in the Oil and Gas Industry

This chart highlights the key challenges facing CCUS adoption in the oil and gas industry, along with the potential advancements and trends expected in the future.

| Challenges | Details | Future Outlook |

| High Costs | CCUS projects are capital-intensive, including capture, transportation, and storage. | Costs are expected to decrease as technology advances and economies of scale are achieved. |

| Infrastructure Development | The lack of extensive infrastructure, such as pipelines and storage facilities, hinders deployment. | Investment in new infrastructure and partnerships between industries and governments are needed. |

| Public Acceptance | Concerns over safety and CO₂ leakage can limit public support for CCUS projects. | Building public trust through education and ensuring robust safety measures will be crucial for acceptance. |

| Scaling Up | Current CCUS projects are not yet deployed at a scale that can significantly reduce emissions. | Large-scale projects will require government support, financing, and collaboration across sectors. |

| Regulatory Uncertainty | Inconsistent regulations and lack of clear policies in some regions slow progress. | More countries are expected to adopt clear CCUS policies to meet climate targets and encourage investment. |

| Long-Term Storage Monitoring | Ensuring the integrity of CO₂ storage over the long term poses technical challenges. | Advancements in monitoring technologies will help guarantee the safe and permanent storage of CO₂. |

| Lack of Economic Incentives | Limited financial incentives and revenue models for CCUS make large investments difficult. | Carbon pricing, tax credits, and emissions trading systems will likely grow, improving economic feasibility. |

| Limited CO₂ Utilization Opportunities | Not all industries have readily available markets for utilizing captured CO₂. | Research into new applications for CO₂ utilization will expand the market and boost commercial viability. |

How Simulation Tools Are Used for CCUS in the Oil and Gas Industry

This chart provides an overview of how oil and gas simulation tools are applied to different aspects of CCUS, supporting both technical and economic decision-making.

| Application | Description | Benefits |

| CO₂ Capture Process Optimization | Simulation models evaluate the efficiency of CO₂ capture technologies, such as chemical absorption and membrane separation. | Helps optimize capture systems, reduce energy consumption, and improve CO₂ separation performance. |

| Reservoir Modeling for CO₂ Storage | Simulations assess the suitability of geological formations (e.g., saline aquifers, depleted oil fields) for long-term CO₂ storage. | Ensures safe and permanent storage by predicting the behavior of CO₂ in subsurface conditions. |

| Injection Process Simulation | Simulates CO₂ injection into reservoirs to evaluate the rate, pressure, and distribution of CO₂ in the storage site. | Enhances control over injection processes, minimizes risks of leakage, and ensures efficient storage. |

| Enhanced Oil Recovery (EOR) Planning | Simulation tools model CO₂ injection for Enhanced Oil Recovery, predicting how much oil can be extracted. | Maximizes oil recovery while simultaneously storing CO₂, optimizing both economic and environmental outcomes. |

| Risk Assessment and Leakage Prevention | Models simulate potential risks such as CO₂ leakage and assess the integrity of storage sites over time. | Provides risk mitigation strategies and ensures compliance with safety regulations for long-term storage. |

| Economic Feasibility Studies | Simulates the financial viability of CCUS projects, considering variables such as carbon pricing and operational costs. | Assists in decision-making by evaluating project economics, ensuring cost-effectiveness and profitability. |

| Environmental Impact Assessment | Tools simulate the environmental impact of CCUS projects, including potential benefits in emissions reduction. | Ensures that CCUS projects align with environmental goals and minimize negative environmental consequences. |

| CO₂ Transport Network Design | Simulates optimal routes and methods for transporting captured CO₂ via pipelines or shipping to storage sites. | Improves the efficiency and safety of CO₂ transport, reducing costs and logistical challenges. |

To sum up, carbon capture utilization and storage represents a powerful tool for the oil and gas industry to mitigate its carbon emissions while maintaining energy production. Through applications such as Enhanced Oil Recovery, gas processing, and hydrogen production, CCUS provides a pathway for the industry to decarbonize its operations and align with global climate targets. As advancements in CCUS carbon capture technology continue and costs decline, the role of CCUS in decarbonizing the oil and gas industry will continuously grow.