How Advancements in Coiled Tubing Technology are Revolutionizing the Oil and Gas Industry

Coiled tubing technology has undergone remarkable advancements in recent years, transforming the oil and gas industry’s approach to well intervention, drilling, and production operations. The evolution of coiled tubing has opened new frontiers in efficiency, safety, and cost-effectiveness. This article explores the significant advancements in coiled tubing technology as well as their implications for the energy sector and how simulation technology used in the optimization of coiled tubing operations.

The Basics of Coiled Tubing in the Oil and Gas Industry

| Aspect | Description |

| Definition | Coiled tubing is a continuous length of steel tubing wound onto a reel, used in oil and gas operations for various downhole applications. |

| Construction | Typically made of high-strength steel alloys to withstand high-pressure and corrosive downhole environments. |

| Diameter | Available in various diameters ranging from 0.75 inches to 2.00 inches, depending on the specific application and well requirements. |

| Length | Coiled tubing lengths can vary widely, commonly ranging from 1,000 to 15,000 feet or more, depending on well depth and operational needs. |

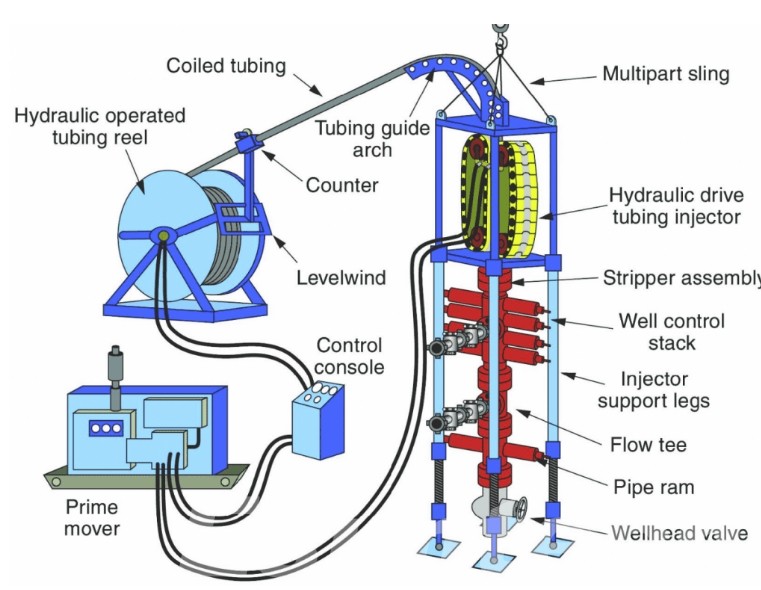

| Deployment | Deployed into the wellbore using a coiled tubing unit (CTU), which consists of a reel, injector, control cabin, and hydraulic power system. |

| Applications | Used for a wide range of applications including well cleanouts, stimulation, acidizing, cementing, drilling, logging, and plug setting. |

| Advantages | Offers faster deployment, reduced rig time, lower cost, improved safety, and increased flexibility compared to conventional tubing methods. |

| Real-time Monitoring | Integrated with sensors and monitoring tools to provide real-time data on downhole conditions, pressure, temperature, and fluid properties. |

| Maintenance and Safety | Requires regular inspection, maintenance, and adherence to safety protocols to ensure integrity and reliability during downhole operations. |

| Industry Standards | Subject to industry standards and regulations such as API specifications and recommended practices governing design, manufacturing, and usage. |

Notable Advancements in Coiled Tubing Technology

1. High-Strength Materials

- The development of high-strength metals and composite materials has enabled the production of coiled tubing strings with higher tensile and burst strengths.

- Advanced materials allow for thinner tubing walls while maintaining structural integrity, resulting in lighter, more flexible coiled tubing that can endure higher pressure and temperature situations.

2. Enhanced Manufacturing Processes

- Manufacturing innovations like as laser welding, precision machining, and non-destructive testing have increased the quality and reliability of coiled tubing.

- These advancements ensure consistent dimensional accuracy, surface finish, and mechanical properties, reducing the risk of defects and failures during operation.

3. Integrated Downhole Tools

- Coiled tubing assemblies now feature a wide range of integrated downhole tools and equipment tailored for specific intervention and completion tasks.

- Advanced downhole tools include logging instruments, milling tools, hydraulic jetting tools, perforating guns, and chemical injection systems, providing operators with versatile capabilities for well maintenance and enhancement.

4. Real-Time Monitoring and Control Systems

- The integration of real-time monitoring and control systems allows operators to remotely monitor downhole conditions and adjust operational parameters in real time.

- Sensors embedded in the coiled tubing string provide data on pressure, temperature, flow rates, and wellbore integrity, enabling proactive decision-making and immediate response to changing downhole conditions.

5. Coiled Tubing Drilling (CTD) Technology

- Coiled tubing drilling (CTD) technology has evolved to enable the efficient drilling of lateral sections, re-entry wells, and sidetracks from existing wellbores.

- CTD systems utilize specialized bottom hole assemblies, including downhole motors, rotary steerable tools, and positive displacement motors, to deliver efficient and cost-effective drilling solutions.

6. Rigless Well Intervention Methods

- Rigless well intervention techniques, such as through-tubing perforation, hydraulic fracturing, and acid stimulation, leverage coiled tubing’s flexibility and mobility to access and intervene in wells without the need for conventional workover rigs.

- These methods offer significant cost savings, reduced environmental footprint, and shorter operational lead times compared to traditional rig-based interventions.

7. Data Analytics and Digitalization

- The integration of data analytics and digitalization tools enables operators to analyze large volumes of well data, optimize operational parameters, and predict equipment performance.

- Predictive maintenance algorithms help identify potential equipment failures before they occur, minimizing downtime and optimizing asset performance.

8. Environmental Considerations

- Advancements in coiled tubing technology have also focused on reducing environmental impact, with the development of biodegradable lubricants, environmentally friendly fluids, and low-emission equipment.

- Rigless interventions and reduced equipment footprint contribute to minimizing disturbance to sensitive ecosystems and habitats.

How Simulation Technology Used in the Optimization of Coiled Tubing Operation

Simulation technology is critical for optimizing coiled tubing operations because it provides operators with vital information about downhole conditions, well performance, and equipment behavior.

1. Wellbore Modeling and Analysis

- Simulation software enables the creation of detailed wellbore models that accurately represent the geometry, formation properties, and completion configuration of the reservoir.

- By inputting data such as well logs, drilling reports, and production history, operators can simulate various scenarios to optimize coiled tubing interventions, such as cleanouts, stimulations, and logging operations.

- Advanced reservoir simulation tools coupled with coiled tubing models allow engineers to predict fluid flow dynamics, pressure changes, and temperature profiles within the wellbore, optimizing operational parameters for maximum efficiency and productivity.

2. Virtual Well Planning and Design

- Coiled tubing simulator allows for virtual well planning and design by simulating the deployment and behavior of coiled tubing strings within the wellbore under various operating conditions.

- Engineers can assess elements including well trajectory, bottomhole assembly design, tubing forces, and hydraulic parameters to guarantee safe and successful coiled tubing operations.

- Through simulation, operators can identify potential issues such as tubing buckling, helical buckling, or differential sticking, allowing for preemptive adjustments to mitigate risks and optimize performance.

3. Hydraulic Modeling and Optimization

- Hydraulic simulation tools simulate fluid flow and pressure distribution within the coiled tubing string and the wellbore, allowing engineers to optimize pumping rates, fluid properties, and nozzle configurations for efficient cleanouts, acid stimulations, or cementing operations.

- By accurately modeling fluid behavior and pressure losses, operators can minimize fluid waste, maintain wellbore integrity, and maximize treatment effectiveness during intervention operations.

4. Torque and Drag Analysis

- Simulation software enables torque and drag analysis to predict the mechanical forces acting on the coiled tubing string as it traverses the wellbore.

- By modeling factors such as friction, bending, and contact with the wellbore, engineers can identify potential areas of high stress or sticking points, optimizing equipment selection and operational parameters to minimize risks of mechanical failure or stuck pipe incidents.

5. Real-Time Monitoring and Control

- Some simulation tools provide real-time monitoring and control, allowing operators to view and evaluate downhole data while coiled tubing operations are underway.

- Real-time simulation feedback helps operators make informed decisions, alter settings quickly, and enhance operating efficiency while maintaining safety and reliability.

6. Training and Education

- Oil and gas simulation technology serves as a valuable training and educational tool for coiled tubing operators and engineers, allowing them to familiarize themselves with complex downhole environments, equipment behavior, and operational challenges in a risk-free virtual environment.

Conclusion

These advancements in coiled tubing technology have revolutionized well intervention, drilling, and production operations, giving operators varied and effective solutions for increasing reservoir productivity while assuring safety, dependability, and environmental responsibility. By utilizing simulation technology in coiled tubing applications, operators may optimize well performance, improving operational efficiency, and reducing hazards, thereby increasing asset productivity and longevity while maintaining safety and environmental stewardship.