Fluid Formulations in Well Completion: A Comprehensive Guide

Fluid formulations play a pivotal role in the well completion process, contributing to the efficiency, safety, and productivity of the well. This article delves into the various types of fluids used in well completion, their functions, compositions and the latest advancements in the fluid formulations for well completion as well as how simulation technology is utilized in the formulation and application of fluids for well completion.

Overview of Well Completion

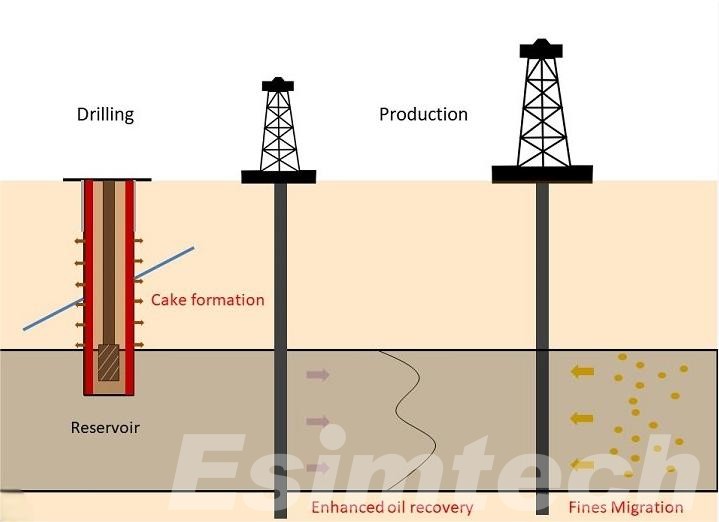

Well completion is the process of making a drilled well ready for production. This involves installing the necessary equipment, perforating the well casing to allow hydrocarbons to flow, and performing other activities to ensure the well’s integrity and productivity. Key goals of well completion include maximizing hydrocarbon recovery, maintaining well stability, and protecting the environment.

Types of Fluids in Well Completion

Fluids used in well completion are specially formulated to perform various tasks such as cleaning the wellbore, maintaining pressure control, preventing formation damage, and enhancing production. The main categories of fluids used in well completion are drilling fluids, completion fluids, and stimulation fluids.

1. Drilling Fluids

Drilling fluids, also known as drilling muds, are used during the drilling phase to facilitate the drilling process. They perform several critical functions, including cooling and lubricating the drill bit, carrying drill cuttings to the surface, and maintaining wellbore stability. The primary types of drilling fluids are:

Water-Based Muds (WBMs)

- Composition: Water as the continuous phase, with clay and other additives.

- Advantages: Cost-effective, environmentally friendly, easy to dispose of.

- Disadvantages: Limited stability at high temperatures and pressures.

Oil-Based Muds (OBMs)

- Composition: Oil is the continuous phase, with water and other additives.

- Advantages: Superior lubricating properties, thermal stability, suitable for challenging drilling conditions.

- Disadvantages: Higher cost, environmental concerns, and complex disposal procedures.

Synthetic-Based Muds (SBMs)

- Composition: Synthetic base fluids, designed to combine the benefits of WBMs and OBMs.

- Advantages: Excellent performance, reduced environmental impact, enhanced wellbore stability.

- Disadvantages: Higher cost compared to WBMs.

2. Completion Fluids

Completion fluids are used after drilling, during the well completion phase. Their primary functions include cleaning the wellbore, balancing formation pressures, and preventing formation damage. Key types of completion fluids include:

Brines

- Composition: Saturated solutions of salts such as sodium chloride (NaCl) or calcium chloride (CaCl2).

- Advantages: High density, stability, and non-damaging to most formations.

- Disadvantages: Potential for corrosion, careful handling required.

Polymer-Based Fluids

- Composition: Water mixed with polymers to enhance viscosity.

- Advantages: Improved suspension of solids, and reduced fluid loss.

- Disadvantages: Potential for formation damage if not properly selected.

Foamed Fluids

- Composition: Gas (e.g., nitrogen or carbon dioxide) dispersed in a liquid phase.

- Advantages: Reduced fluid density, minimized formation damage, enhanced carrying capacity.

- Disadvantages: Complexity in formulation and handling.

3. Stimulation Fluids

Stimulation fluids are designed to enhance the production of hydrocarbons from a well by improving the permeability of the reservoir rock. Hydraulic fracturing, or fracking, is a common method that uses these fluids. Main components of stimulation fluids include:

Proppants

- Composition: Solid particles like sand, ceramic, or resin-coated particles.

- Function: Keep fractures open after the hydraulic pressure is released.

- Advantages: Enhanced hydrocarbon flow, and sustained production rates.

Gelling Agents

- Composition: Polymers or crosslinked gels to increase fluid viscosity.

- Function: Improve the suspension and transport of proppants.

- Advantages: Efficient proppant delivery, and improved fracture propagation.

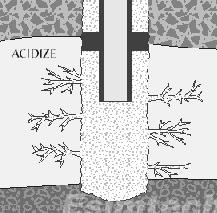

Acids

- Composition: Typically hydrochloric acid (HCl).

- Function: Dissolve rock formations, and enhance permeability.

- Advantages: Increased flow paths, effective in carbonate formations.

- Disadvantages: Potential for corrosion, handling hazards.

Technological Advancements in Fluid Formulations for Well Completion

The field of well completion has seen significant advancements in fluid formulations, driven by the need for improved efficiency, safety, and environmental sustainability. These innovations are transforming how the oil and gas industry prepares wells for production, ensuring better performance and reduced environmental impact.

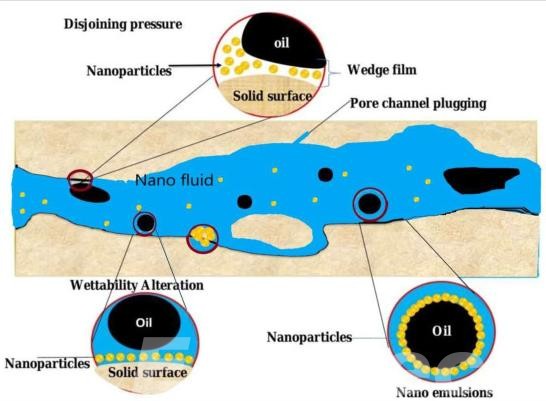

1. Nanotechnology in Fluid Formulations

Nanotechnology has introduced revolutionary changes to well completion fluids. Nanoparticles are engineered to enhance the physical and chemical properties of fluids, offering several benefits:

Enhanced Thermal Stability

Nanoparticles can significantly improve the thermal stability of drilling fluids, making them more effective in high-temperature environments. This is crucial for deep wells where temperatures can exceed the limits of conventional fluids.

Improved Lubricity

Adding nanoparticles to drilling fluids reduces friction between the drill bit and the wellbore, enhancing the drilling efficiency and reducing wear on equipment. This leads to longer-lasting drill bits and lower operational costs.

Strengthened Cement

Nanoparticles can be incorporated into cement slurries to increase their strength and durability. This results in better wellbore sealing, reducing the risk of leaks and improving the long-term integrity of the well.

Enhanced Proppant Conductivity

In hydraulic fracturing, nanoparticles can improve the conductivity of proppants, allowing for better flow of hydrocarbons through the fractures. This leads to higher production rates and more efficient resource extraction.

2. Environmentally Friendly Formulations

The oil and gas industry is under increasing pressure to minimize its environmental impact. Recent advancements in fluid formulations have focused on developing more eco-friendly options:

Biodegradable Polymers

Polymer-based fluids are essential in well completion, but traditional polymers can be harmful to the environment. The development of biodegradable polymers ensures that these fluids break down naturally, reducing their environmental footprint.

Non-Toxic Additives

Replacing toxic chemicals with non-toxic alternatives has been a major focus. This includes using plant-based or synthetic additives that are less harmful to the environment and safer for workers handling the fluids.

Recyclable Fluids

Innovations in fluid formulations have led to the creation of recyclable fluids. These fluids can be reused multiple times, significantly reducing waste and the environmental impact of well completion operations.

3. Real-Time Monitoring and Control

The integration of real-time monitoring technologies with fluid formulations has revolutionized well completion processes. These technologies provide continuous data on well conditions, allowing for dynamic adjustments to fluid properties:

Downhole Sensors

Downhole sensors measure various parameters such as temperature, pressure, and fluid composition in real time. This data helps operators optimize fluid formulations on the fly, ensuring the fluids perform optimally under changing well conditions.

Fiber-Optic Systems

Fiber-optic systems provide real-time monitoring of the wellbore, offering insights into the fluid behavior and well integrity. This allows for immediate adjustments to fluid properties, enhancing the efficiency and safety of well completion operations.

Automated Control Systems

Automated control systems use real-time data to make precise adjustments to fluid formulations. This reduces human error, improves consistency, and enhances the overall efficiency of well completion.

4. Advanced Chemical Formulations

Innovations in chemical formulations have led to the development of advanced fluids with superior performance characteristics:

Smart Fluids

Smart fluids can change their properties in response to specific well conditions. For example, they can adjust their viscosity based on temperature or pressure changes, ensuring optimal performance throughout the well completion process.

Self-Healing Fluids

Self-healing fluids can repair minor damages or leaks in the wellbore, enhancing the long-term integrity of the well. These fluids contain additives that react to damage, forming a seal that prevents further fluid loss or contamination.

High-Performance Brines

Advancements in brine formulations have resulted in high-performance brines that offer superior density control and stability. These brines can be tailored to specific well conditions, providing better pressure control and minimizing formation damage.

Key Ways Simulation Technology is Used in the Fluid Formulations for Well Completion

1. Predicting Fluid Behavior

Computational Fluid Dynamics (CFD)

CFD is widely used to simulate the behavior of fluids under various well conditions. This includes predicting how fluids will flow through the wellbore, interact with the formation, and carry out their intended functions.

- Flow Dynamics: Simulations can predict how drilling and completion fluids will flow through different well geometries and formations. This helps in designing fluids that maintain stability and effectiveness throughout the completion process.

- Thermal Properties: CFD models can simulate temperature changes and their effects on fluid properties, ensuring the fluid maintains its performance in high-temperature environments.

Reservoir Simulation

Reservoir simulation involves modeling the reservoir’s response to different fluid formulations. This helps in understanding how the fluids will interact with the reservoir rock and fluids, and in optimizing the formulation for maximum effectiveness.

- Formation Interaction: Simulations can predict how completion and stimulation fluids will interact with the reservoir rock and fluids. This helps in selecting formulations that minimize formation damage and maximize hydrocarbon recovery.

- Pressure and Saturation: By simulating the pressure and fluid saturation changes in the reservoir, engineers can optimize fluid properties to ensure effective pressure control and fluid displacement.

2. Optimizing Fluid Properties

Rheological Modeling

Rheological models simulate the flow and deformation of fluids under various conditions. This helps in designing fluids with the desired viscosity and flow characteristics.

- Viscosity Control: Simulations can predict how changes in temperature, pressure, and composition will affect fluid viscosity. This ensures that fluids have the appropriate viscosity for efficient wellbore cleaning, proppant transport, and pressure control.

- Gel Strength: For polymer-based and foamed fluids, rheological modeling helps in optimizing gel strength and stability, ensuring effective proppant transport and formation sealing.

Chemical Reaction Modeling

Simulations of chemical reactions between fluid components and formation materials help in optimizing the composition of completion and stimulation fluids.

- Acidizing: Chemical reaction models can predict the interactions between acidizing fluids and reservoir rock. This helps in selecting acid formulations that effectively dissolve rock and enhance permeability without causing excessive damage.

- Crosslinking: For gelling agents, simulations can optimize the crosslinking reactions that control gel formation and stability. This ensures effective proppant transport and fluid loss control.

3. Designing and Testing Fluid Systems

Virtual Wellbore Modeling

Virtual wellbore models simulate the entire well completion process, allowing engineers to test different fluid formulations and strategies in a virtual environment.

- Scenario Analysis: Engineers can simulate various well completion scenarios to identify the best fluid formulations and strategies for different well conditions. This reduces the risk of unexpected issues during actual completion operations.

- Optimization: By testing multiple formulations and strategies, virtual wellbore modeling helps in optimizing fluid systems for maximum efficiency and effectiveness.

4. Reducing Environmental Impact

Environmental Impact Modeling

Simulations can predict the environmental impact of different fluid formulations, helping in the development of more sustainable and eco-friendly options.

- Fluid Disposal: Simulating the behavior of fluids during and after well completion helps in designing fluids that are easier to handle and dispose of, minimizing environmental impact.

- Eco-Friendly Formulations: By modeling the environmental interactions of different fluid components, engineers can develop formulations that reduce toxicity and environmental harm.

Lifecycle Assessment

Simulations can assess the entire lifecycle of well completion fluids, from production to disposal, ensuring that the most sustainable practices are employed.

- Resource Use: Lifecycle assessments help in optimizing the use of resources in fluid formulations, reducing waste and environmental footprint.

- Sustainability Metrics: By modeling the sustainability metrics of different fluid systems, engineers can select the most eco-friendly options for well completion operations.

Conclusion

Fluid formulations are integral to the success of well completion in the oil and gas industry. The careful selection and application of these fluids ensure wellbore stability, enhance production rates, and minimize environmental impact.

Oil and gas simulation technology has become an essential tool for well completion. Through using advanced computational models and simulations, engineers can optimize fluid formulations, predict performance, and address potential issues before they arise in the field.