Exploring the Oil Rigs on Land: Key Components, Operation and Technical Innovations

Oil rigs aren’t confined to offshore locations alone. Land-based oil rigs can be found in many places of the world, drilling deep into the Earth’s crust to obtain precious fossil fuels. This article will delve into the intriguing world of oil rigs on land, their operation, and technological innovations for improving the efficiency of land-based oil drilling operations.

What are Oil Rigs On Land

Structures used to extract crude oil and natural gas from beneath the Earth’s surface are known as oil rigs on land. In terms of design, operation, and environmental impact, they differ greatly from offshore oil rigs.

What are the Key Components of Oil Rigs On Land

Derrick

The most visible element of a land-based oil rig is the towering derrick. It supports the drilling equipment structurally and acts as a guide for the drilling components.

Drilling Rig

This is where the equipment for drilling into the Earth is kept. The drilling bit, the drilling mud system, and the power units that power the entire operation are all part of it.

Mud Pumps

Oil drilling produces a considerable amount of drilling debris and heat. Mud pumps circulate drilling mud (a mixture of water, clay, and different chemicals) through the borehole to cool the drill bit, lubricate the drill string, and remove cuttings.

Mud Tanks

These tanks hold the drilling mud, allowing it to be easily recirculated during the drilling process.

Wellhead

The wellhead is the wellbore’s endpoint and offers a secure seal to prevent oil and gas from leaking into the environment.

What is the Operation Process of Oil Rigs On Land

Site Preparation

The contraction procedure of land-based oil rigs begins with the selection of a suitable drilling location, which includes geologic surveys and permitting.

Drilling

Once the rig is in place, drilling commences. The drilling bit is rotated, creating a borehole that can extend thousands of feet into the Earth. Drilling mud is continuously pumped down the borehole to cool the bit, remove cuttings, and maintain wellbore integrity.

Casing Installation

Steel casing pipes are inserted into the borehole to prevent its collapse, isolate geological formations, and protect groundwater from contamination.

Well Completion

After reaching the desired depth, the well is completed by installing cement between the casing and the surrounding rock to create a secure seal.

Production

If the well is productive, oil and gas are brought to the surface using pumps. These resources are then transported for refining, processing, and distribution.

What are Technical Innovations for Oil Rigs On Land

Technical innovations for oil rigs on land have significantly increased the efficiency, safety, and sustainability of land-based oil drilling operations. The necessity to produce oil and natural gas more effectively, comply with environmental rules, and increase safety precautions has spurred these advancements.

Automation and Remote Monitoring

Automated drilling systems: These systems use advanced sensors and software to optimize drilling parameters, reducing human error and improving drilling efficiency.

Remote monitoring: Real-time data from rigs can be transmitted to remote control centers, enabling experts to monitor operations, make adjustments, and respond to issues promptly.

Digital Twin Technology

Drilling digital twin models, such as the 3D drilling and well control simulation systems, assist operators in visualizing and simulating rig performance, making it easier to recognize possible difficulties and optimize drilling processes.

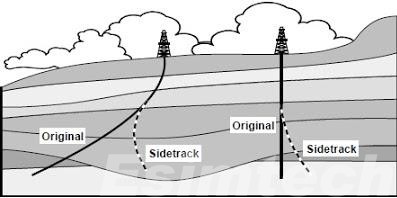

Directional Drilling and Extended Reach Drilling

Advances in drilling techniques, such as horizontal and extended-reach drilling, enable operators to explore previously uneconomical oil resources.

Electrification and Hybrid Power Systems

Transitioning from diesel generators to electrified or hybrid power systems minimizes pollutants, lowers operational costs, and improves energy efficiency.

High-Performance Drilling Equipment

Cutting-edge drill bits, drilling motors, and downhole tools have improved drilling speed, accuracy, and reliability.

Drilling Fluid and Cuttings Management

Drilling fluids that are environmentally friendly, such as synthetic-based muds or vegetable-based oils, lessen the environmental impact of drilling operations.

Underbalanced Drilling

This technology involves maintaining reservoir pressure during drilling, enhancing safety and reservoir recovery rates.

Advanced Sensors and Data Analytics

Sensors provide real-time data on drilling parameters, equipment conditions, and environmental conditions. Data analytics help optimize drilling processes and equipment maintenance.

Borehole Sealing and Well Control Systems

Enhanced well control technology improves safety and minimizes the risk of blowouts and oil spills.

Modular Rig Designs

Modular rig designs allow for quicker rig setup and dismantling, reducing downtime and transportation costs.

Eco-Friendly Drilling Fluids

Environmentally friendly drilling fluids, such as synthetic-based muds or vegetable-based oils, reduce the environmental impact of drilling operations.

Solar and Wind Power Integration

Some land-based rigs are integrating renewable energy sources like solar panels and wind turbines to power non-drilling operations, reducing the rig’s carbon footprint.

Drone Technology

Drones are utilized to improve operational efficiency and safety by conducting airborne surveys, environmental monitoring, and safety inspections.

Wellbore Imaging Tools

LWD (Logging While Drilling) and MWD (Measurement While Drilling) advanced imaging systems give real-time subsurface data to improve drilling trajectories and increase reservoir contact.

Advanced Cementing and Wellbore Isolation

Innovations in cementing technology improve wellbore integrity and reduce the risk of leakage and environmental contamination.

Hydraulic Fracturing Technologies

Multi-stage fracking and micro-seismic monitoring are two innovations in hydraulic fracturing procedures that improve oil and gas recovery from unconventional sources.

Conclusion

Oil rigs on land are an essential component of the global energy economy. They are critical in the extraction of the fossil fuels that power our contemporary society. While they provide economic benefits and help to ensure energy security, the environmental challenges and regulatory duties associated with land-based drilling make it a contentious issue. As the oil and gas evolves, technological innovations will be important in meeting the world’s energy demands while avoiding environmental concerns.