Exploring Offshore Production: Technological Advancements, Challenges and How Simulation Used in It

The extraction of valuable resources from beneath the ocean floor, known as offshore production, is a testament to human ingenuity and determination. This method of resource extraction is becoming increasingly important in meeting the world’s increasing energy demands. In this article, we will look at the complexities of offshore production, including technological advancements, environmental concerns, and the critical role of simulation technology in offshore production.

Technological Advances in Offshore Production

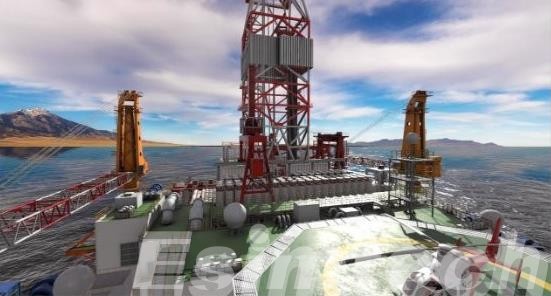

One of the defining characteristics of offshore production is the continuous evolution of cutting-edge technologies. From the early days of fixed platforms to today’s state-of-the-art floating structures, the industry has embraced innovation to unlock energy resources in deeper and more challenging waters.

Modern offshore rigs use advanced drilling techniques such as directional drilling and extended reach drilling to reach reservoirs located kilometers beneath the ocean floor. Automation and robotics have improved efficiency and safety by streamlining operations. The integration of real-time data analytics and artificial intelligence has improved production processes even further.

Environmental Considerations for Offshore Production

While offshore production has significantly contributed to global energy supplies, it has also come under scrutiny due to its environmental impact. Oil spills, habitat destruction, and emissions are all issues that must be addressed. The industry, on the other hand, has responded with strict regulations, technological solutions, and proactive environmental management.

Technological advancements in spill response, such as subsea capping systems and remotely operated vehicles (ROVs), demonstrate the industry’s commitment to minimizing environmental damage. Additionally, ongoing research into cleaner drilling fluids and environmentally friendly rig designs reflects a broader shift toward sustainability.

Challenges of Offshore Exploration and Production

When compared to onshore activities, offshore exploration and production present unique challenges. The harsh marine environment, which includes corrosive saltwater, extreme weather, and the logistical challenges of working in remote locations, necessitates specialized knowledge.

Deep-sea drilling presents difficulties due to high pressure and temperature conditions. Concerns about safety loom large, necessitating stringent training programs and continuous improvement in safety protocols. Despite these obstacles, the industry has an admirable safety record, with ongoing efforts to improve operational security.

How Simulation Technology Used in Offshore Production

Simulation technology has evolved to meet the complex demands of offshore production, from virtual training scenarios to advanced digital twin models.

1. Training and Skill Development

Virtual Reality (VR) and Augmented Reality (AR): Working in challenging and hazardous environments is part of offshore production. Immersive training experiences are enabled by VR and AR technologies, which allow personnel to simulate various scenarios, from routine operations to emergency responses, in a safe and controlled virtual environment. This helps offshore personnel develop and hone their skills without exposing them to real-world risks.

2. Drilling and Reservoir Simulation

Dynamic Well Control Simulation: Dynamic well control scenarios are modeled using simulation tools, allowing drillers and engineers to practice and fine-tune their responses to well control incidents. This improves readiness for unexpected events during drilling operations.

Reservoir Modeling: Engineers can create digital models of subsurface reservoirs using advanced reservoir simulation software. These models aid in the prediction of reservoir behavior, the optimization of well placement, and the maximization of hydrocarbon recovery.

3. Operational Decision Support

Digital Twin Technology: Digital twins are virtual replicas of physical assets or systems. In the offshore production context, a digital twin can represent an entire offshore platform, including its infrastructure, equipment, and operational processes. This technology provides real-time insights, allowing operators to monitor, analyze, and optimize performance.

Integrated Operations Centers: oil and gas simulation tools are employed in integrated operations centers to create a comprehensive view of offshore assets. This centralized monitoring allows for data-driven decision-making, predictive maintenance, and optimization of production processes.

4. Emergency Response and Safety Training

Emergency Response Simulations: emergency training simulator is used to simulate scenarios such as oil spills, fires, and equipment failures during emergency response drills. These drills aid in assessing the effectiveness of emergency procedures and improving the preparedness of response teams.

Evacuation Simulations: In the event of an emergency, offshore personnel may need to evacuate the platform. Evacuation simulations assess evacuation plans, including the use of lifeboats and evacuation routes, ensuring that personnel can safely and efficiently leave the facility.

5. Logistics and Supply Chain Optimization

Supply Chain Simulations: production and transportation simulation in oil and gas are utilized to optimize logistics and supply chain operations, taking into account factors such as transportation, inventory management, and procurement. This helps in minimizing downtime and reducing costs associated with offshore production.

6. Weather and Environmental Impact Analysis

Weather Simulation: Weather conditions have a significant impact on offshore operations. Weather patterns are modeled and predicted using simulation technology, allowing operators to plan and adjust production schedules based on anticipated environmental conditions.

Environmental Impact Assessments: Simulation tools aid in assessing the potential environmental impact of offshore activities, such as oil spills or discharges. This proactive approach helps in implementing measures to minimize environmental damage.

Conclusion

Offshore production is still a vital and dynamic component of the global energy mix. With ongoing technological advancements and a commitment to environmental stewardship, the industry is poised to navigate future challenges, ensuring a secure and sustainable energy future for future generations. As the industry continues to evolve, the integration of advanced simulation technologies will play a key role in enhancing efficiency, safety, and sustainability.