Enhanced Oil Recovery (EOR) and Improved Oil Recovery (IOR) Technology in Petroleum Industry

Oil recovery from reservoirs is a complex process influenced by various factors. Generally, only a portion of the total oil present in a reservoir can be extracted using primary recovery methods, typically ranging from 5% to 30%. This leaves a significant amount of oil untapped. However, through the application of advanced techniques such as Enhanced Oil Recovery (EOR) and Improved Oil Recovery (IOR), it becomes possible to increase the amount of oil recovered from a reservoir beyond what is achievable with primary methods.

EOR vs. IOR: A Spectrum of Techniques

Enhanced Oil Recovery (EOR) and Improved Oil Recovery (IOR) represent vital strategies within the petroleum industry aimed at maximizing oil extraction from reservoirs. Both methodologies share the overarching goal of augmenting oil yield but diverge significantly in their methodologies and objectives.

EOR encompasses a spectrum of techniques characterized by the introduction of external substances into the reservoir environment to modify either the properties of the oil or the reservoir rock. This alteration facilitates the movement of oil towards production wells, thereby enhancing recovery rates. Examples of EOR techniques include steam injection, where high-pressure steam is introduced to reduce oil viscosity and improve flow, and chemical injection, where polymers or surfactants are employed to alter fluid behavior and displace trapped oil.

In contrast, IOR techniques are geared towards optimizing the efficiency of existing extraction methodologies without fundamentally altering reservoir characteristics. Water flooding, a common IOR technique, involves the injection of water into the reservoir to push oil towards production wells by displacing it. Similarly, the application of surfactants aids in reducing interfacial tension between oil and water, enhancing oil mobility within the reservoir.

Despite their divergent approaches, both EOR and IOR play crucial roles in extending the productive lifespan of oil reservoirs and maximizing resource recovery. Their implementation underscores the industry’s commitment to innovation and efficiency in meeting global energy demands while navigating increasingly complex geological challenges.

Common Techniques

The world of EOR and IOR encompasses a diverse range of techniques, each with its own unique strengths and applications. Let’s delve deeper into some of the most common methods:

- Thermal Recovery:

- Steam Flooding: This is a well-established EOR technique highly effective for heavy oil reservoirs. Hot steam is injected into the reservoir through injection wells, heating the surrounding rock and oil. The increased temperature reduces oil viscosity, making it flow more freely towards production wells. Steam flooding requires a significant amount of energy and water to generate the steam, making it a relatively expensive technique.

- In-Situ Combustion: This method involves a controlled underground fire within the reservoir. Air or oxygen is injected, and a small portion of the oil is ignited. The combustion process generates heat that mobilizes the surrounding oil, similar to steam flooding. However, in-situ combustion requires careful monitoring to avoid uncontrolled burning and potential environmental damage.

2. Chemical Enhanced Oil Recovery:

- Polymer Flooding: In this IOR technique, specially formulated polymers are added to the injected water. These polymers increase the viscosity of the water, improving its sweep efficiency. This translates to better contact between the injected water and the oil, displacing a greater volume of oil towards producing wells. Polymer flooding is a relatively cost-effective IOR method and can be applied to a wider range of reservoir conditions compared to some other EOR techniques.

- Surfactant Flooding: Surfactants are chemicals that lower the interfacial tension between oil and water. Imagine oil and water as separate beads. Surfactants act like a soap, allowing these beads to merge and become more mobile. This allows previously trapped oil to flow more readily towards producing wells. Surfactant flooding can be particularly effective for lighter oils but can be more expensive than polymer flooding due to the specialized chemicals involved.

3. Gas Injection:

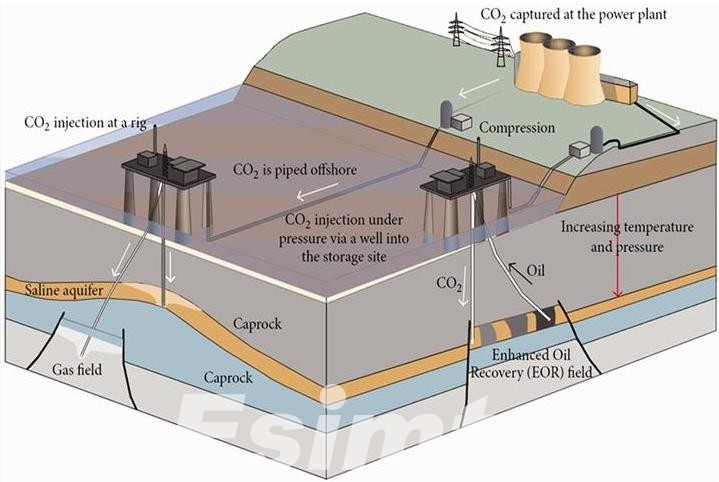

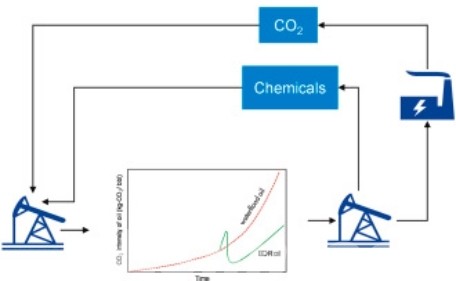

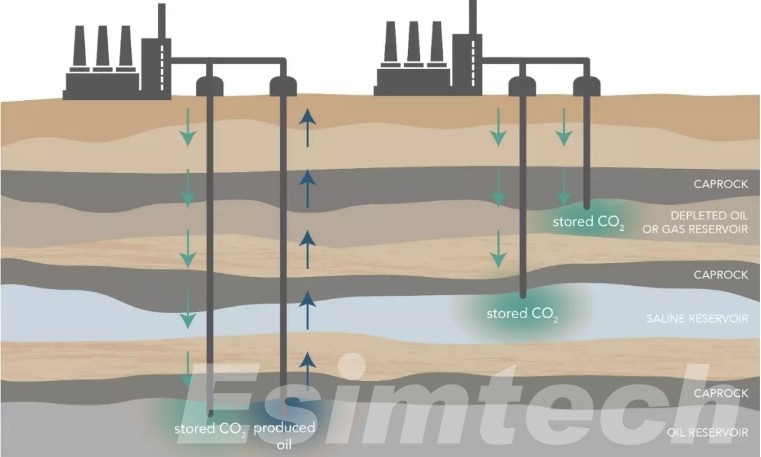

- Miscible Gas Flooding: This EOR technique utilizes miscible gases, typically carbon dioxide (CO2), which can mix with the oil at reservoir conditions. The injected gas reduces the oil’s viscosity and allows it to flow more easily. Additionally, CO2 flooding can have the added benefit of acting as a form of carbon capture and storage (CCS) as the injected CO2 remains trapped underground. However, miscible gas flooding is highly dependent on reservoir pressure and oil properties for successful mixing to occur.

- Water-Alternating-Gas (WAG) Injection: This IOR method involves injecting water and gas alternately into the reservoir. The water helps to maintain reservoir pressure and displace oil, while the gas improves sweep efficiency by reducing the channeling of water through the reservoir. WAG injection offers a cost-effective approach compared to some other EOR techniques and can be applied to a wider range of reservoir conditions.

4. Improved Recovery Techniques:

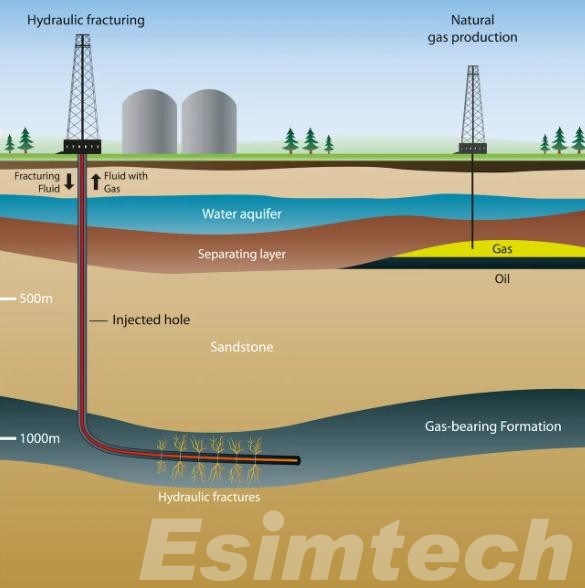

- Waterflooding Optimization: As the name suggests, this IOR method focuses on optimizing the process of waterflooding, the most common secondary recovery technique. Advanced monitoring and modeling techniques are used to design efficient water injection patterns that maximize contact with the remaining oil. Additionally, wellbore stimulation techniques like hydraulic fracturing or acidizing can be employed to improve the flow of injected water and oil production from existing wells.

- Infill Drilling: This IOR strategy involves strategically placing additional wells within an existing oil field. This helps to improve sweep efficiency by increasing the number of drainage points for the remaining oil. Infill drilling can be particularly beneficial for mature fields where the original well spacing may not have been optimized for maximum recovery.

It’s important to note that this is not an exhaustive list, and new EOR and IOR technologies are constantly being developed. The choice of the most suitable technique depends on a thorough evaluation of the specific reservoir characteristics, economic feasibility, and environmental considerations.

Factors Affecting EOR/IOR Selection

Choosing the right EOR/IOR technique for a specific reservoir is a complex decision influenced by a multitude of factors. Here’s a closer look at some key considerations that play a crucial role in the selection process:

1. Reservoir Characteristics:

- Geology: The geological structure of the reservoir, including its heterogeneity (variations in rock properties), presence of faults and fractures, and overall dip angle, significantly impacts EOR/IOR effectiveness. For instance, thermal recovery methods may not be suitable for highly fractured reservoirs due to excessive heat loss.

- Rock Properties: The porosity and permeability of the rock formation determine how easily fluids can flow through it. Tight reservoirs with low permeability may benefit more from chemical EOR methods that improve oil mobility, while highly permeable formations might be better suited for waterflooding optimization techniques.

- Oil Viscosity: The viscosity, or “thickness,” of the oil heavily influences its flow behavior. Heavy oils with high viscosity require techniques that reduce viscosity, such as thermal recovery or solvent injection. Conversely, lighter oils may respond well to waterflooding optimization or gas injection methods.

2. Economic Feasibility:

- Cost of Implementation: Different EOR/IOR methods vary significantly in cost. Advanced EOR techniques like in-situ combustion or complex chemical flooding can be expensive to implement, requiring specialized equipment and expertise. IOR methods, on the other hand, often involve lower upfront costs and can be more readily applied to a wider range of fields.

- Expected Incremental Oil Recovery: The potential increase in oil production due to the EOR/IOR technique needs to justify the investment. A thorough economic analysis is crucial, considering factors like oil prices, project timelines, and operational costs. Techniques with a higher predicted recovery rate might be more attractive, even if the initial investment is higher.

3. Environmental Considerations:

- Water Usage: Some EOR/IOR techniques, particularly waterflooding and polymer flooding, require significant water volumes. In water-scarce regions, alternative methods with lower water footprints might be preferred. Additionally, the proper disposal of produced water after treatment becomes crucial.

- Greenhouse Gas Emissions: Techniques like thermal recovery methods can generate greenhouse gas emissions due to fuel combustion for steam generation. Selecting methods with lower emissions or utilizing carbon capture and storage (CCS) technologies can help mitigate environmental impact.

- Surface Footprint: Some EOR/IOR methods, particularly thermal recovery with extensive steam generation facilities, require a larger surface footprint. This can be a concern in environmentally sensitive areas or densely populated regions.

4. Operational Considerations:

- Reservoir Maturity: The maturity of the reservoir, or the percentage of OOIP already recovered, influences EOR/IOR selection. Mature fields with lower remaining oil volumes might benefit more from targeted and cost-effective IOR techniques. Conversely, younger fields with higher remaining oil saturation might be candidates for more advanced and potentially expensive EOR methods.

- Infrastructure Availability: The existing infrastructure in the field plays a role. Techniques requiring specialized equipment or extensive modifications to existing wells might be less favorable compared to methods that can utilize existing infrastructure with minimal modifications.

- Regulatory Environment: Local regulations governing environmental impact, water usage, and waste disposal can influence the feasibility of certain EOR/IOR methods. Selecting a technique that complies with all regulations is essential.

By carefully evaluating these factors and conducting thorough reservoir characterization studies, oil companies can make informed decisions about EOR/IOR selection. Utilizing reservoir simulation software to model different scenarios and predict the potential outcomes of various techniques further enhances the selection process.

The Role of Simulation Technology for EOR and IOR

Simulation technology stands as a cornerstone in the planning, optimization, and assessment of Enhanced Oil Recovery (EOR) and Improved Oil Recovery (IOR) initiatives. Advanced reservoir simulators serve as indispensable tools, enabling engineers to replicate intricate fluid-flow dynamics within reservoirs, anticipate reservoir responses across diverse operational scenarios, and refine production strategies accordingly. Through the simulation of numerous EOR/IOR scenarios, operators gain insights into the viability, cost-effectiveness, and efficiency of various approaches, ultimately striving to maximize oil recovery while mitigating risks and uncertainties.

These simulations provide valuable data to guide decision-making processes, allowing operators to identify optimal injection rates, injection compositions, and well placement strategies. Additionally, simulators facilitate the assessment of reservoir performance over time, aiding in the identification of potential challenges and the refinement of production plans to ensure long-term viability.

Overall, simulation technology empowers oil and gas companies to make informed decisions throughout the lifecycle of EOR/IOR projects, optimizing resource utilization, enhancing operational efficiency, and ultimately contributing to the sustainable extraction of hydrocarbon reserves.

Conclusion

EOR and IOR technologies are essential tools for maximizing oil recovery and extending the life of existing oil fields. By utilizing a spectrum of techniques, from advanced EOR methods to optimized IOR processes, the industry can ensure efficient resource utilization while minimizing its environmental impact. As technology continues to evolve, we can expect even more innovative EOR and IOR methods to emerge, shaping a more sustainable future for oil production.