Electric Wireline vs. Slickline: Choosing the Right Well Intervention Method

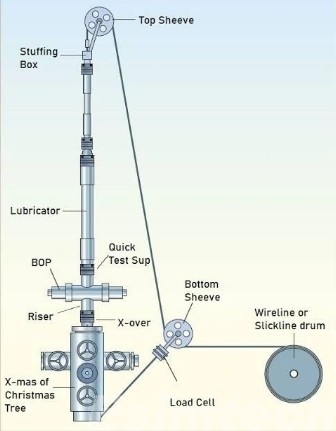

In the oil and gas industry, well intervention is essential for maintaining the performance and productivity of wells over time. Two critical tools used in well intervention operations are electric wireline and slickline. While both techniques involve running a cable or wire into the wellbore, their functions, advantages, and applications differ significantly. Understanding these differences between electric wireline vs. slickline, is essential for selecting the right method for specific well intervention needs.

What is Electric Wireline?

Electric wireline is a type of cable used in the oil and gas industry for downhole operations in wells. It is equipped with electrical conductors that allow the transmission of both power and data signals between the surface and the downhole tools. Unlike slickline, which is purely mechanical, electric wireline enables more sophisticated operations by allowing the operation of downhole tools that require electrical power, real-time data transmission, and continuous monitoring.

Electric wireline is primarily used for well intervention activities that require the deployment, retrieval, or operation of advanced tools and equipment, including logging tools, perforating guns, sensors, and other devices that need electrical power or communication with the surface. These operations might include well logging, pressure and temperature monitoring, formation evaluation, downhole testing, and perforating operations.

Key Features

- Electrical Conductors: Electric wireline includes conductors for transmitting electrical signals to and from downhole tools.

- Real-Time Data: It enables real-time data transmission for operations such as well logging and testing, providing operators with valuable downhole information.

- Advanced Tool Deployment: Electric wireline is designed to deploy and operate more complex downhole tools that require electrical power.

- Dual Purpose: It can be used for both power delivery to downhole tools and for data collection, offering a more comprehensive solution for well intervention.

Applications

- Well Logging: Measuring various parameters like temperature, pressure, and formation characteristics.

- Perforating: Deploying perforating guns to create flow paths in the casing.

- Downhole Testing: Monitoring well conditions such as pressure, temperature, and other environmental factors.

- Tool Deployment: Running sophisticated tools, such as gauges or sensors, that require power and data transmission.

Electric wireline is a crucial tool for operations requiring precise control, monitoring, and real-time feedback, making it indispensable for complex well intervention tasks.

What is Slickline?

Slickline is a type of wireline that is made from a solid steel cable, which is used for mechanical tasks in well intervention operations. Unlike electric wireline, slickline does not have electrical conductors and is purely mechanical, meaning it cannot transmit power or data. It is designed for simpler operations that involve deploying, retrieving, or manipulating downhole tools, but without the need for electrical control or data transmission.

Key Features

- Solid Steel Cable: Slickline is made of strong, flexible steel, which makes it durable and capable of withstanding high tensions and mechanical stress.

- Non-Electrical: It does not contain electrical conductors, so it is used for mechanical operations that do not require power transmission or data communication.

- Simple and Cost-Effective: Slickline is generally more affordable and easier to maintain than electric wireline, as it lacks complex electrical components.

Applications

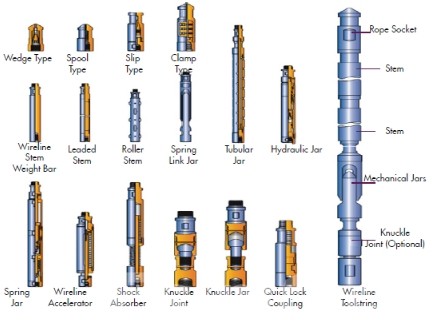

- Tool Retrieval: Slickline is commonly used to retrieve mechanical tools that were previously deployed downhole, such as plugs, valves, and other equipment.

- Valve Manipulation: It is used to open or close downhole valves, such as sliding sleeves or gas lift valves.

- Plug Setting and Retrieval: Slickline can set or retrieve plugs used to isolate sections of the wellbore for pressure testing or other operations.

- Fishing Operations: In case tools or equipment are stuck downhole, slickline can be used for fishing operations to retrieve or remove these objects.

Slickline is well-suited for operations that require simple, mechanical interventions without the need for electrical power or real-time data feedback. Its cost-effectiveness and reliability make it an excellent choice for routine and less complex well intervention tasks.

Key Differences Between Electric Wireline and Slickline

This comparison provides a clear distinction between the electric wireline vs. slickline, aiding in selecting the most suitable well intervention technique based on operational needs.

| Aspect | Electric Wireline | Slickline |

| Definition | Multi-strand, insulated cable with electrical conductors for data transmission and tool control | Single-strand, non-conductive wire used for mechanical well interventions |

| Primary Function | Data acquisition, well diagnostics, and precision interventions | Tool retrieval, valve adjustments, and routine well maintenance |

| Real-Time Data Transmission | Yes, allows real-time communication between surface and downhole tools | No, operates without real-time data feedback |

| Well Depth Suitability | Suitable for deep and complex wells | More effective for shallow and simple wells |

| Cost | Higher due to specialized equipment and personnel | Lower, requiring minimal setup and expertise |

| Tool Deployment Control | High precision, allowing for controlled placement and activation | Limited precision, mainly for basic mechanical operations |

| Resistance to Harsh Conditions | May be affected by extreme temperatures and corrosive fluids | More resistant to high temperatures and aggressive chemical environments |

| Speed of Operation | Slower due to setup complexity and data acquisition | Faster due to simpler deployment and operation |

| Common Applications | Well logging, perforation, plug setting, video inspection, fishing operations | Setting and retrieving downhole tools, removing obstructions, routine maintenance |

Choosing Between Electric Wireline vs. Slickline

The decision to use electric wireline or slickline depends largely on the complexity of the task at hand. Electric wireline is required for operations that involve sophisticated tool deployments, real-time data transmission, and downhole monitoring. Some examples of situations where electric wireline is essential include:

- Running advanced downhole sensors for logging and formation evaluation.

- Perforating the well to create flow channels in the casing.

- Conducting downhole testing for pressure and temperature monitoring.

- Deploying complex tools like multi-phase meters and logging tools.

Slickline, on the other hand, is better suited for simpler tasks that do not require electrical control. Common situations where slickline would be the preferred choice include:

- Retrieving tools that do not require electrical control.

- Manipulating downhole valves or sleeves.

- Setting or retrieving plugs to isolate sections of the wellbore.

- Performing routine maintenance or light mechanical tasks.

In many cases, oil and gas operators may use both systems in different stages of a well intervention program. For example, slickline might be used to set a plug, and then electric wireline could be used to deploy a sensor to monitor pressure in the wellbore. By using both systems effectively, operators can ensure a more efficient, cost-effective, and reliable intervention process.

The Role of Simulation Technology in Optimizing Operations of Electric Wireline and Slickline

This chart provides a clear overview of how oil and gas simulation technology optimizes both electric wireline and slickline operations, helping to improve performance, reduce risks, and enhance cost-effectiveness in well interventions.

| Aspect | Electric Wireline | Slickline |

| Real-Time Performance Prediction | Simulates electrical systems, power transmission, and data flow for tool operation | Simulates mechanical operations like tool retrieval and valve manipulation under various well conditions |

| Tool Deployment and Optimization | Optimizes deployment of electrical tools, ensuring proper functioning in the wellbore | Optimizes deployment of mechanical tools, improving retrieval and operation methods |

| Risk Reduction and Failure Prevention | Identifies electrical or mechanical failures, improving troubleshooting and maintenance | Predicts mechanical failures like line breakage or tool sticking, mitigating risks before operations |

| Enhanced Decision-Making | Helps in determining optimal tool setup, logging timing, and well intervention strategies | Aids in choosing the best technique for mechanical interventions, minimizing downtime |

| Cost and Time Efficiency | Reduces trial-and-error by optimizing operations and improving equipment setup | Cuts down operational costs and time by identifying the most effective retrieval methods |

| Training and Skill Development | Provides training for complex operations like data monitoring and tool deployment under electrical systems | Offers a safe platform for training in mechanical tool deployment and valve manipulation |

| Predicting and Managing Wellbore Conditions | Simulates changing wellbore conditions and their impact on electrical tool performance | Models wellbore pressure and temperature conditions, optimizing tool performance under varying conditions |

| Integrated Simulation Platforms | Allows integration of various electric tools into a unified model for efficient operations | Integrates different mechanical tools in a unified simulation, enhancing decision-making in intervention strategies |

Summary

Electric wireline and slickline serve as essential tools in well intervention, each playing a specific role depending on the complexity of the task. Electric wireline is ideal for complex, data-driven operations that require real-time monitoring and control, while slickline excels in simpler, mechanical interventions that do not require electrical capabilities. The right choice between these two tools depends on the specific needs of the operation, the equipment required, and the level of complexity involved. Understanding the distinct features and functions of electric wireline vs. slackline can ensure that the best tool for the job, leading to more efficient and cost-effective well intervention operations.

Through providing virtual environments to simulate downhole conditions, simulation technology has become a vital tool for optimizing the use of both electric wireline and slickline, allowing engineers to predict tool performance, prevent failures, and optimize intervention strategies for both electric and mechanical operations, which improving efficiency, cost savings, and enhancing safety in well intervention operations.