Effective Strategies for Well Cementing in Offshore and Deepwater Wells

Well cementing is critical in the construction and integrity of oil and gas wells, particularly in deepwater and offshore environments. These challenging settings demand precise engineering and innovative solutions to ensure safety, environmental protection, and operational efficiency. This article explores the key aspects, challenges, and advancements in well cementing for deepwater and offshore wells.

Purpose of Well Cementing in Offshore and Deepwater Wells

The purpose of well cementing in offshore and deepwater wells is crucial to ensure the safety of the well.

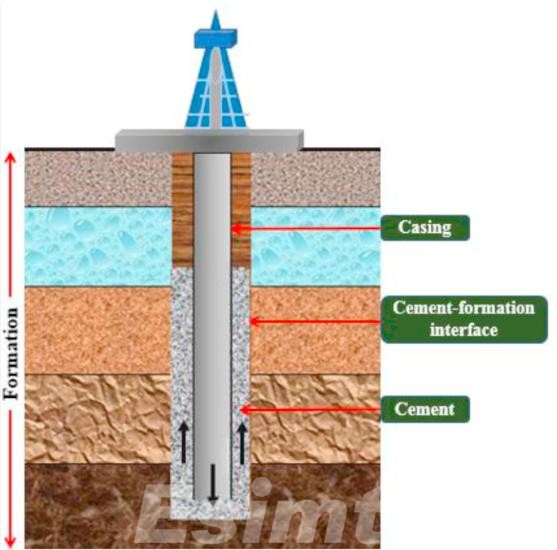

- Zonal Isolation: Prevents the migration of fluids between different subsurface layers. Ensures proper containment of hydrocarbons within the designated zones, avoiding contamination of aquifers or other non-target zones.

- Structural Support: Provides mechanical support to the casing, helping it withstand the pressures and stresses of the deepwater environment. Stabilizes the wellbore, preventing collapses or deformations.

- Well Integrity: Acts as a seal to protect the casing from corrosive formation fluids and external pressures. Cementing maintains the well’s structural integrity throughout its life cycle, from drilling to production and eventual abandonment.

- Pressure Management: Ensures that the well can handle high pressures encountered in deepwater reservoirs. Cementing helps manage pressure changes during production and well interventions.

- Safety Enhancement: Mitigates the risk of blowouts by creating barriers against uncontrolled fluid flow. Contributes to environmental protection by preventing leaks into the surrounding seabed and water column.

- Preparation for Subsequent Operations: Creates a firm foundation for well completion and installation of additional equipment, such as production tubing and wellheads. Enables safe and efficient drilling of deeper sections of the well.

- Well Abandonment: Facilitates safe and permanent plugging of the well at the end of its lifecycle, ensuring no residual risks to the environment or nearby wells.

Challenges of Well Cementing in Deepwater and Offshore Wells

This chart provides a structured overview of the challenges, highlighting their causes and impacts on well cementing operations in offshore and deepwater wells.

| Category | Challenges | Impact |

| HPHT Well Conditions | Extreme pressure and temperature in deep formations. | Requires specialized cement to maintain integrity under stress. |

| Narrow Operational Windows | Small margin between pore pressure and fracture gradient. | Increases the risk of wellbore instability and cement loss. |

| Deepwater Currents | Unstable subsea environments and currents disrupting cement placement. | Affects cementing precision and zonal isolation. |

| Temperature Gradients | Significant differences between seabed and downhole temperatures. | Impacts cement slurry performance and setting time. |

| Weak Formations | Fragile zones that may fracture under cement weight. | Necessitates lightweight or foamed cement solutions. |

| Mud Removal | Ineffective displacement of drilling mud before cementing. | Reduces cement bonding, leading to compromised zonal isolation. |

| Logistical Challenges | Complex offshore operations involving remote and subsea facilities. | Increases time and costs; requires precise planning and execution. |

| Regulatory Compliance | Strict environmental and operational safety requirements. | Demands eco-friendly additives and robust monitoring systems. |

| Environmental Sensitivity | Potential for hydrocarbon leaks impacting marine ecosystems. | Requires self-healing cements and leak detection technologies. |

| Cost Constraints | High costs associated with specialized equipment and materials. | Challenges economic feasibility of offshore cementing projects. |

Advancements in Well Cementing Technologies for Deepwater and Offshore Wells

Innovative technologies adopted for Well cementing in deepwater and offshore environments to address the unique challenges of these settings.

1. Thermal-Resistant and HPHT Cements

Purpose: Designed to endure extreme pressures and temperatures in deep formations.

Features:

- Latex-modified cement for flexibility and durability.

- Silica-enhanced formulations to resist strength retrogression at high temperatures.

Benefits: Ensures long-term integrity under harsh downhole conditions.

2. Foamed Cementing Systems

Purpose: Ideal for use in weak or low-fracture-gradient formations.

Features

- Gas (usually nitrogen) is mixed with the slurry to reduce its density.

- Maintains strength and provides better zonal isolation.

Benefits: Reduces the risk of formation damage and wellbore instability.

3. Self-Healing Cements

Purpose: Automatically repair cracks and restore zonal isolation when exposed to fluids.

Features

- Incorporates reactive additives that expand upon contact with hydrocarbons or water.

- Compatible with HPHT environments.

Benefits: Minimizes the risk of long-term leaks and enhances well safety.

4. Advanced Slurry Design and Simulation Tools

Purpose: Tailors cement properties to specific well conditions.

Features

- Computer-aided design to optimize density, viscosity, and setting time.

- Oil and gas simulation tools can predictive modeling to assess cement behavior during placement and curing.

Benefits: Improves efficiency and reduces operational risks.

5. Real-Time Monitoring and Control Systems

Purpose: Ensures precision in cement placement and identifies potential issues.

Features

- Downhole sensors for temperature, pressure, and fluid flow.

- Real-time data transmission and analysis.

Benefits: Enables proactive adjustments to prevent cement failures.

6. Cementing Additives and Enhancers

Purpose: Improve the performance and adaptability of cement slurries.

Features

- Viscosifiers and retarders to control flow and setting times.

- Eco-friendly additives to comply with stringent regulations.

Benefits: Enhances bonding strength, reduces environmental impact, and adapts to various conditions.

7. Rotary Steerable and Placement Tools

Purpose: Improve the precision of cement placement in complex well trajectories.

Features

Advanced nozzles and tools for uniform slurry distribution.

Zonal isolation packers for effective sealing in challenging zones.

Benefits: Achieves effective cement coverage and minimizes formation damage.

8. Nano-Enhanced Cements

Purpose: Boosts the mechanical and thermal properties of cement.

Features

- Nanoparticles improve strength, permeability, and resistance to wear.

- Enhanced resistance to chemical degradation.

Benefits: Provides long-lasting performance in extreme environments.

9. Digital Twin Technology

Purpose: Simulates real-time well cementing processes for better planning and execution.

Features

- Creates a virtual replica of the wellbore.

- Analyzes multiple scenarios to optimize cementing strategies.

Benefits: Reduces risks, improves efficiency, and enhances decision-making.

Best Practices for Well Cementing in Deepwater and Offshore Wells

This structured chart highlights the best practices in deepwater and offshore well cementing, emphasizing their purposes and benefits for successful operations.

| Category | Challenges | Impact |

| HPHT Well Conditions | Extreme pressure and temperature in deep formations. | Requires specialized cement to maintain integrity under stress. |

| Narrow Operational Windows | Small margin between pore pressure and fracture gradient. | Increases the risk of wellbore instability and cement loss. |

| Deepwater Currents | Unstable subsea environments and currents disrupting cement placement. | Affects cementing precision and zonal isolation. |

| Temperature Gradients | Significant differences between seabed and downhole temperatures. | Impacts cement slurry performance and setting time. |

| Weak Formations | Fragile zones that may fracture under cement weight. | Necessitates lightweight or foamed cement solutions. |

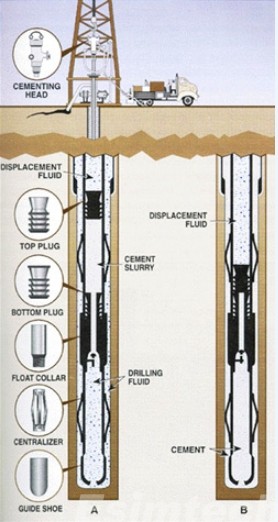

| Mud Removal | Ineffective displacement of drilling mud before cementing. | Reduces cement bonding, leading to compromised zonal isolation. |

| Logistical Challenges | Complex offshore operations involving remote and subsea facilities. | Increases time and costs; requires precise planning and execution. |

| Regulatory Compliance | Strict environmental and operational safety requirements. | Demands eco-friendly additives and robust monitoring systems. |

| Environmental Sensitivity | Potential for hydrocarbon leaks impacting marine ecosystems. | Requires self-healing cements and leak detection technologies. |

| Cost Constraints | High costs associated with specialized equipment and materials. | Challenges to economic feasibility of offshore cementing projects. |

To sum up, well cementing in deepwater and offshore wells is a sophisticated process and is a critical component for the success of exploration and production operations. While challenges abound, advancements in technology and best practices ensure safer, more efficient, and environmentally responsible operations.