Digitalization and Data Analytics in Oil and Gas Drilling

Digitalization and data analytics have emerged as revolutionary factors in the oil and gas industry’s ever-changing landscape, affecting the way drilling operations are carried out. The incorporation of sophisticated technologies increases not only operational efficiency but also safety, cuts costs, and provides vital insights. This article examines the impact of digitalization and data analytics on oil and gas drilling, highlighting technological advancements that are catapulting the industry into a new era of intelligent exploration and extraction, as well as how simulation technology is used for enhancing digitalization and data analytics in oil and gas drilling.

Understanding Digitalization and Data Analytics in Oil and Gas Drilling

Digitalization in Oil and Gas Drilling

- Smart Drilling Systems

Smart drilling systems that use real-time data to optimize drilling processes have emerged as a result of digitalization. These systems integrate sensors and monitoring devices into drilling equipment, providing continuous data streams on variables such as temperature, pressure, and drill bit performance. This real-time data enables operators to make informed decisions promptly, enhancing drilling efficiency and minimizing downtime.

- Automated Drilling Rigs

Automation has emerged as a critical component of digitalization in oil and gas drilling. Drilling rigs that are fully automated using artificial intelligence (AI) and machine learning (ML) algorithms to analyze data and make autonomous decisions. These rigs can dynamically modify drilling parameters in response to subsurface conditions in real time, resulting in better drilling accuracy and overall efficiency.

- Internet of Things (IoT) Integration

The Internet of Things (IoT) is critical to the digitalization of drilling operations. Data is collected and transmitted to a centralized system via sensors and devices distributed throughout the drilling infrastructure. This integrated network enables complete monitoring, predictive maintenance, and drilling process optimization.

Data Analytics Revolutionizing Drilling Operations

- Predictive Maintenance

Predictive maintenance is enabled by data analytics, which analyzes equipment performance data to identify probable breakdowns. By predicting when components may require maintenance, operators can schedule proactive interventions, reducing downtime and extending the lifespan of critical drilling equipment.

- Geospatial Analytics for Site Selection

Advanced geospatial analytics aid in selecting optimal drilling sites. By analyzing geological and geographical data, including seismic surveys and subsurface structures, operators can make informed decisions about where to drill, maximizing the likelihood of successful extraction.

- Real-time Monitoring and Decision-Making

Drilling operators can monitor activities in real time thanks to real-time data analytics. Decision-makers can optimize drilling procedures and ensure safety and efficiency by continuously analyzing drilling parameters, geological data, and equipment performance.

- Reservoir Modeling and Simulation

Data analytics make reservoir modeling and simulation easier by allowing operators to generate digital representations of subsurface formations. Engineers can model multiple extraction scenarios, improving well placement and extraction processes for maximum reservoir recovery, by integrating geological, geophysical, and drilling data.

Key Benefits and Challenges of Digitalization and Data Analytics in Oil and Gas Drilling

Benefits

| Aspect | Description |

| 1. Enhanced Operational Efficiency | Real-time monitoring and optimization of drilling operations. Automation of routine tasks for increased efficiency. |

| 2. Improved Decision-Making | Data-driven insights for informed decision-making. Predictive analytics for risk assessment and mitigation. |

| 3. Cost Reduction | Efficient resource allocation and reduced downtime.Predictive maintenance to minimize equipment failures. |

| 4. Increased Safety | Real-time monitoring of drilling parameters and safety conditions.Early detection of potential issues for proactive intervention. |

| 5. Enhanced Environmental Compliance | -Monitoring and mitigating environmental impacts through data analysis.Compliance with regulations and standards. |

Challenges

| Aspect | Description |

| 1. Data Security and Privacy Concerns | Protection of sensitive drilling data from cyber threats.Ensuring compliance with data privacy regulations. |

| 2. Integration of Legacy Systems | Challenges in integrating new digital technologies with existing infrastructure.Potential disruptions during the transition phase. |

| 3. Skill Gap and Workforce Training | Need for skilled professionals in data analytics and digital technologies. Training existing workforce for the adoption of digital tools. |

| 4. Data Quality and Reliability | Ensuring accuracy and reliability of data for meaningful analysis.Dealing with data inconsistencies and quality issues. |

| 5. Initial Capital Investment | Upfront costs for implementing digitalization and analytics solutions.Balancing short-term costs with long-term benefits. |

How Simulation Technology Used for Digitalization and Data Analytics in Oil and Gas Drilling

Simulation technology is critical in the advancement of digitalization and data analytics in oil and gas drilling. It is a sophisticated tool for developing virtual models that mirror the intricacies of drilling operations, allowing engineers and operators to simulate various situations, analyze data, and make informed decisions.

1. Reservoir Modeling and Simulation

Simulation Technology Contribution

Reservoir Characterization: Simulation models allow for the production of detailed reservoir representations that include geological, geophysical, and petrophysical data.

Fluid Flow Dynamics: Simulations aid in understanding reservoir fluid flow dynamics, anticipating pressure changes, and improving extraction procedures.

Recovery Optimization: Engineers can optimize well placement, drilling procedures, and reservoir recovery tactics by simulating various extraction scenarios.

Benefits

Improved decision-making by visualizing reservoir behavior.

Optimization of well configurations for maximum recovery.

Better understanding of subsurface conditions.

2. Drilling Process Simulation

Simulation Technology Contribution

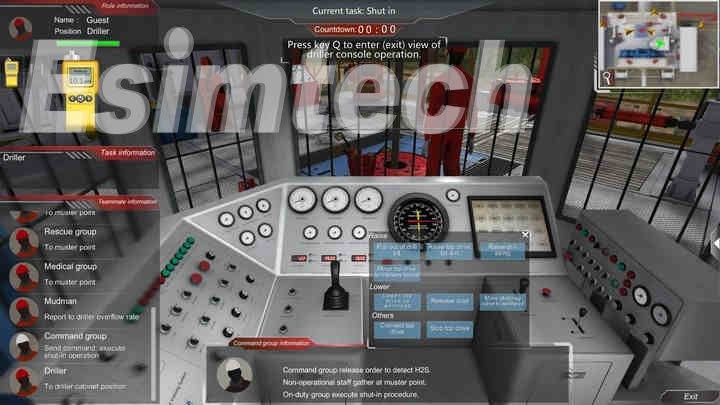

Digital Twin Creation: Simulation creates digital twins of drilling equipment and processes, replicating real-world conditions.

Real-time Parameter Analysis: Drilling simulators allow real-time analysis of drilling parameters such as pressure, temperature, and torque.

Dynamic Drilling Scenarios: Virtual drilling scenarios help identify potential challenges and optimize drilling strategies.

Benefits

Enhanced training for drill operators in a risk-free virtual environment.

Real-time monitoring and analysis for efficient decision-making.

Identification and mitigation of potential drilling challenges.

3. Predictive Maintenance Simulations

Simulation Technology Contribution

Failure Mode Simulations: Based on historical and real-time data, virtual simulations model potential failure modes of drilling equipment.

Maintenance Optimization: Simulations forecast equipment maintenance requirements, allowing schedules to be optimized for minimal downtime.

Condition-Based Monitoring: Continuous simulations enable condition-based monitoring for early detection of equipment issues.

Benefits

Increased equipment lifespan through proactive maintenance.

Reduction in unplanned downtime and associated costs.

Improved overall reliability of drilling equipment.

4. Wellbore Stability and Trajectory Simulation

Simulation Technology Contribution

Geomechanical Simulations: Simulations assess wellbore stability by considering geomechanical factors.

Trajectory Optimization: Virtual simulations aid in the optimization of well paths in order to avoid geological difficulties.

Real-time Adjustments: Simulations give real-time data that can be used to change drilling parameters to maintain stability.

Benefits

Preventing wellbore instability problems.

Well trajectory optimization for effective drilling.

Improved knowledge of subsurface conditions.

5. Integrated Operations and Digital Twins

Simulation Technology Contribution

Integrated Digital Twins: Simulations help to build integrated digital twins that model the complete drilling ecology.

Data Fusion: Simulation technology facilitates the integration of data from many sources, such as sensors and IoT devices.

Cross-Disciplinary Collaboration: Geologists, engineers, and data scientists may collaborate in a single digital environment thanks to digital twins.

Benefits

A full perspective of drilling activities is required for comprehensive decision-making.

Improved cross-disciplinary problem-solving collaboration.

Enhanced data integration and analytics capabilities.

Conclusion

Digitalization and data analytics are ushering in a new era of oil and gas drilling efficiency and intelligence. Smart drilling equipment, automation, IoT, and sophisticated analytics are transforming traditional drilling techniques, providing benefits such as higher operational efficiency, cost savings, and improved safety. The use of simulation technology in the digital revolution of oil and gas drilling is critical. As simulation technology becomes more integrated, its impact on boosting efficiency, lowering costs, and increasing safety in oil and gas drilling operations will become more pronounced.