Conventional vs. Unconventional Drilling in Oil and Gas

As the world’s reliance on oil and gas continues, the methods used to extract these resources are constantly evolving. Two distinct approaches dominate the industry: conventional drilling and unconventional drilling. Understanding the key differences between these methods is crucial for navigating the complexities of the oil and gas sector.

Conventional Drilling

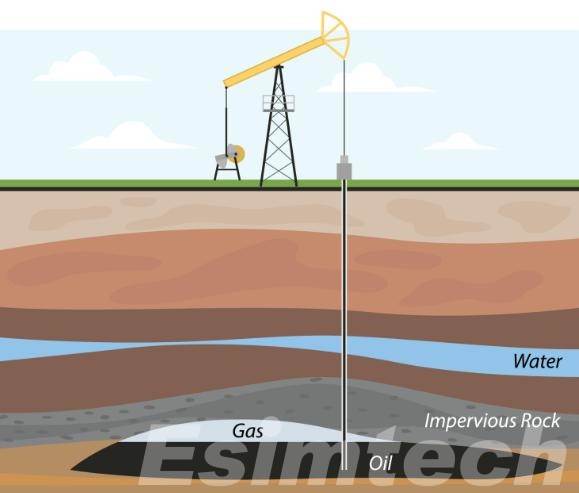

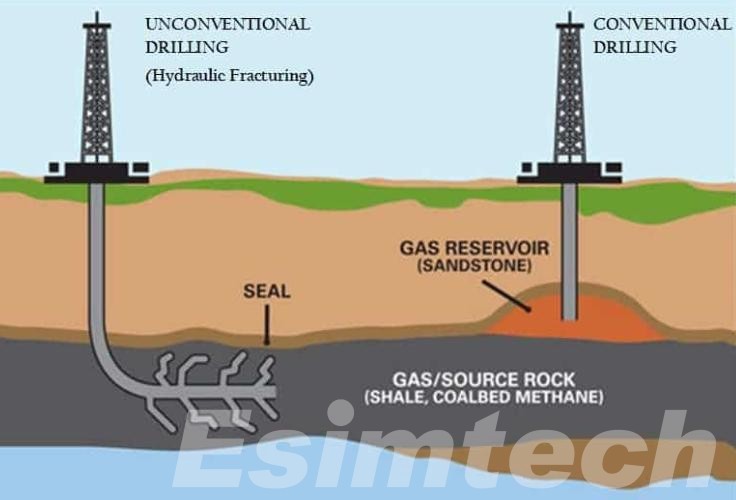

Conventional drilling, the cornerstone of the oil and gas industry for over a century, relies on targeting naturally occurring pockets of oil and gas trapped within porous rock formations. These formations, often sandstone or limestone, have sufficient pore space between rock grains to allow hydrocarbons to accumulate and flow relatively freely. The drilling process itself is relatively straightforward. A drill rig lowers a drill bit attached to a long string of drill pipe into the earth. As the bit excavates, steel casing lines the wellbore, protecting it from collapse and safeguarding freshwater aquifers above the target reservoir. While elegant in its simplicity, conventional drilling is limited by geology.

Easily accessible reserves tend to be depleted first, necessitating exploration for more unconventional sources of oil and gas as global demand persists. However, conventional drilling still plays a vital role in the industry, particularly for mature oil fields where well-established infrastructure exists. It remains a valuable and well-understood technique for extracting resources from these proven conventional reservoirs.

Unconventional Drilling

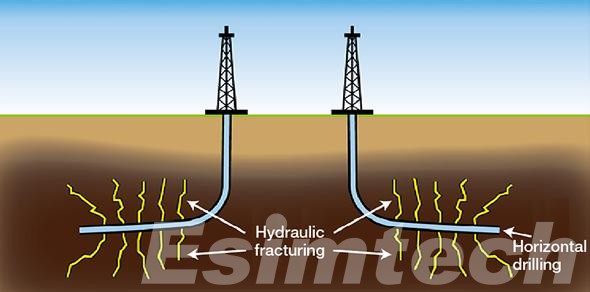

Unconventional drilling tackles the challenge of extracting resources from less accessible or geologically complex formations. These formations, like shale or tight sand, have low permeability, meaning oil and gas cannot flow freely through the rock. Unconventional drilling methods, such as horizontal drilling and hydraulic fracturing (fracking), are employed to unlock these reserves.

- Horizontal Drilling: This technique deviates from the vertical path, creating a long wellbore within the target formation. Imagine a drill bit burrowing sideways for thousands of feet! This maximizes the amount of rock exposed and increases production compared to a straight wellbore.

- Hydraulic Fracturing (Fracking): Fracking involves injecting a high-pressure fluid mixture (water, sand, and chemicals) into the formation to create cracks. Think of it like using a pressurized liquid wedge to split the rock. These cracks allow trapped oil and gas to flow more freely to the wellbore, making extraction possible.

Unconventional drilling has revolutionized the oil and gas industry by providing access to vast reserves that were previously unreachable. However, it’s a more complex and technology-intensive process compared to conventional drilling.

While unconventional drilling offers significant advantages in resource recovery, it’s crucial to acknowledge the ongoing debate surrounding its environmental impact. Concerns exist regarding water contamination from fracking fluids, potential for induced seismic activity, and overall impact on air and water quality. The industry is constantly working on improving practices and developing more sustainable methods to address these concerns.

Conventional vs. Unconventional Drilling: Key Differences

Here we summarize the key differences between conventional and unconventional drilling, diving deeper into some aspects:

| Feature | Conventional Drilling | Unconventional Drilling |

| Target Formations | Easily accessible, porous rock | Less accessible, low permeability formations |

| Wellbore Trajectory | Vertical | Vertical, directional, or horizontal |

| Technology Complexity | Lower | Higher, with techniques like fracking |

| Production Rate | Typically faster initially | Slower initial production, but can be sustained longer |

| Recovery Rate | Lower | Can be higher due to accessing more rock |

| Environmental Impact | Generally considered lower | Potential for water contamination and seismic activity with fracking |

Cost vs. Environmental Impact

The trade-off between cost and environmental impact is a significant consideration when choosing a drilling method.

- Cost: Conventional drilling is generally cheaper due to its simpler technology and faster well completion times. A single vertical well can be drilled and operational relatively quickly. Unconventional drilling, on the other hand, requires more complex techniques and equipment, leading to higher upfront costs. Horizontal drilling necessitates longer wellbores, and fracking adds another layer of complexity and expense.

- Environmental Impact: Conventional drilling typically has a lower environmental footprint. Since it targets shallower depths and requires less land disturbance, the potential for disrupting ecosystems or contaminating groundwater is generally lower. Unconventional drilling, particularly fracking, raises environmental concerns. The large volumes of water used in fracking can strain local water resources, and there is a risk of contamination if the fracking fluids migrate into freshwater aquifers. Additionally, fracking has been linked to increased seismic activity in some regions.

The environmental impact of both conventional and unconventional drilling can be mitigated through responsible practices. Regulatory frameworks and technological advancements can help minimize water usage in fracking, and proper wellbore construction can safeguard against groundwater contamination.

The Future of Oil and Gas Drilling: Innovation and Sustainability

As the industry seeks to meet energy demands while minimizing environmental impact, advancements in drilling technology are crucial. Here are some areas shaping the future of oil and gas drilling:

- Continuous Improvement in Drilling Efficiency: Automation, advanced drilling tools, and real-time data analysis are constantly improving drilling accuracy and speed, reducing costs and environmental impact.

- Development of Closed-Loop Fracking Systems: These systems aim to capture and reuse fracking fluids, significantly reducing water usage and the risk of contamination.

- Research into Alternative Well Stimulation Methods: New techniques are being explored that could unlock unconventional resources without relying on fracking, potentially reducing the environmental footprint.

- Increased Focus on Renewable Energy Sources: As renewable energy technologies become more cost-competitive and efficient, they will play a growing role in the global energy mix, reducing reliance on oil and gas in the long term.

By understanding conventional drilling and unconventional drilling, we gain insight into the methods used to extract vital resources. As technology progresses, the oil and gas industry can strive for a future that balances energy security with environmental responsibility. The path forward lies in embracing innovation, adopting sustainable practices, and transitioning towards a more diversified energy landscape.